You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

50mm x 40mm Mild steel

- Thread starter ukracer

- Start date

Tried no where yet I cocked up and ordered 4 bearings the same size. Turns out one of the 3 is actually a 6304. So I need to go back out in the morning to get one.Have you tried Acton bright steel?

I will be going near the place I use for steel and will phone for a price before I go. But I can investigate a few more places to make sure I am not paying over the odds.

Is hot rolled worse or better for my application, that's the question.Looking at the price list, m-machine metals have 40 x 60 hot rolled at about half that? Also have 40 x 50 bright flats, but they're similar to the price you already have..

It's to make T2 size Dickson Tool Holders. I could do with another 10.

pressbrake1

Forum Supporter

- Messages

- 5,284

Wouldn’t use mild steel, mild steel I’d call mild steel for a reason. Or put it another way I’d use mild steel if I had a bit in stock but if I was going to spend money I’d get something more suitable.Is hot rolled worse or better for my application, that's the question.

It's to make T2 size Dickson Tool Holders. I could do with another 10.

Sometimes it’s cheaper and easier to source round then cut it into square

Agroshield

Member

- Messages

- 4,764

Please correct me if I am wrong, but I assume you are going to cut off 100mm slices of the 40 x 50 bar to make the toolholders.

Most things I have seen making these holders cut off 50mm slices from a 100 x 40+ bar.

There are some advantages to doing it this way as you can gang mill all the back dovetail features into the big bar before cutting it down.

The overall dimensions of a T2 are shown as 40 x 50 and if you buy stock to these same dimensions, it will need at least a skim to bring it square and parallel.

Most things I have seen making these holders cut off 50mm slices from a 100 x 40+ bar.

There are some advantages to doing it this way as you can gang mill all the back dovetail features into the big bar before cutting it down.

The overall dimensions of a T2 are shown as 40 x 50 and if you buy stock to these same dimensions, it will need at least a skim to bring it square and parallel.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,371

- Location

- Don't ask questions

I've been planning on doing this for years, need a few round tuits before I finally get there though.Most things I have seen making these holders cut off 50mm slices from a 100 x 40+ bar.

There are some advantages to doing it this way as you can gang mill all the back dovetail features into the big bar before cutting it down.

And I agree with PB and Brad, get some posh steel if you want them to last.

- Messages

- 21,575

- Location

- Birmingham

No mate. Trying to research what I am supposed to be asking for now my cheap basic Mild Steel on size has been thoroughly trashed. Lol

Just checked them out. It would seem logical to buy it ready cut as they add 5mm to the size to allow for out of square.

40 X 50 x100 is £11 plus vat per chunk. And does not seem to go down in price for extra quantity.

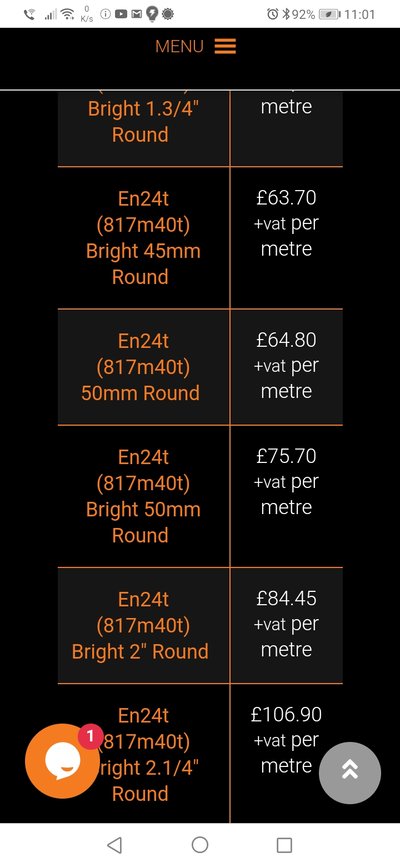

Yeah it does seem like round is cheaper but I don't know the different use of Bright or the other listed.Wouldn’t use mild steel, mild steel I’d call mild steel for a reason. Or put it another way I’d use mild steel if I had a bit in stock but if I was going to spend money I’d get something more suitable.

Sometimes it’s cheaper and easier to source round then cut it into square

- Messages

- 21,575

- Location

- Birmingham

Just checked them out. It would seem logical to buy it ready cut as they add 5mm to the size to allow for out of square.

40 X 50 x100 is £11 plus vat per chunk. And does not seem to go down in price for extra quantity.

Once you know what you want, it may be worth phoning them for a price?, websites give you an idea of prices, but a chat may get you a better price.

Please correct me if I am wrong, but I assume you are going to cut off 100mm slices of the 40 x 50 bar to make the toolholders.

Most things I have seen making these holders cut off 50mm slices from a 100 x 40+ bar.

There are some advantages to doing it this way as you can gang mill all the back dovetail features into the big bar before cutting it down.

The overall dimensions of a T2 are shown as 40 x 50 and if you buy stock to these same dimensions, it will need at least a skim to bring it square and parallel.

Not yet.Have you tried Acton bright steel?

Well....looking at what I wrote you would assume that. BUT my original plan was for 100 X 40 for the reason you suggest. Slicing of 50mm and doing dovetail in one go is appealing but I was trying to price 50 X 40 versus 100 X 40 as the larger stuff is less prevalent on eBay and size for size more expensive (this was mild steel though.)Please correct me if I am wrong, but I assume you are going to cut off 100mm slices of the 40 x 50 bar to make the toolholders.

Most things I have seen making these holders cut off 50mm slices from a 100 x 40+ bar.

There are some advantages to doing it this way as you can gang mill all the back dovetail features into the big bar before cutting it down.

The overall dimensions of a T2 are shown as 40 x 50 and if you buy stock to these same dimensions, it will need at least a skim to bring it square and parallel.

As for finished dimension. It's not that critical on the tool holder side and I hate the idea of paying more and cutting it away when the crucial measurements are the dovetail side anyway.

Agroshield

Member

- Messages

- 4,764

...EN16 as a minimum, EN24 would be better, then they could be hardened...

What advantage does hardening confer on a toolholder please? They will need a lot more attention to preventing stress risers on the internal corners of the tool clamping pocket if they are to be hardened. Possibly the critical surfaces will need to be ground after hardening to remove distortion. For anything other than production work, it probably is not worth it.

It might also be useful to discuss the machinability of EN16 & EN24 compared to a lesser steel and other available heat treatment processes (e.g. nitriding) if a tough skin is thought desirable.

The wear on mine is limited to the opening and closing of the round plunger that locks it to the dovetail (tool change) and very occasional opening and closing of the capscrews that secure the tool.

Agroshield

Member

- Messages

- 4,764

...was trying to price 50 X 40 versus 100 X 40 as the larger stuff is less prevalent on eBay

The advantage of going for a bigger lump is that it opens up the option of a plasma or flame cut piece out of S275 or S355 plate.

Yeah I like the sound of that. Let's discuss ease of machining.What advantage does hardening confer on a toolholder please? They will need a lot more attention to preventing stress risers on the internal corners of the tool clamping pocket if they are to be hardened. Possibly the critical surfaces will need to be ground after hardening to remove distortion. For anything other than production work, it probably is not worth it.

It might also be useful to discuss the machinability of EN16 & EN24 compared to a lesser steel and other available heat treatment processes (e.g. nitriding) if a tough skin is thought desirable.

The wear on mine is limited to the opening and closing of the round plunger that locks it to the dovetail (tool change) and very occasional opening and closing of the capscrews that secure the tool.

The only dealing I have with stress risers is my wife.