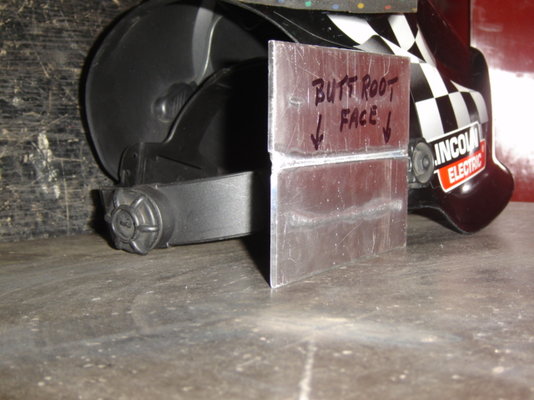

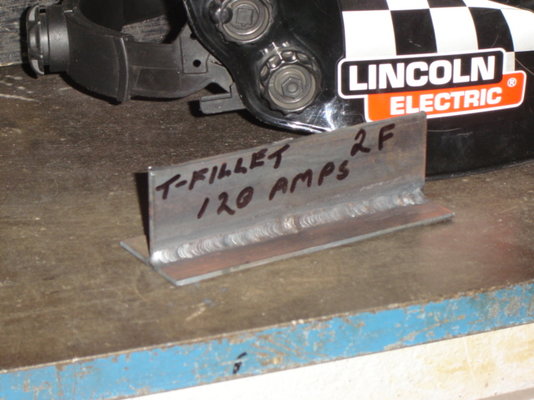

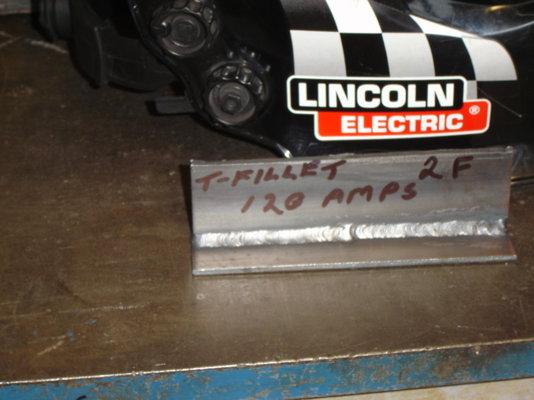

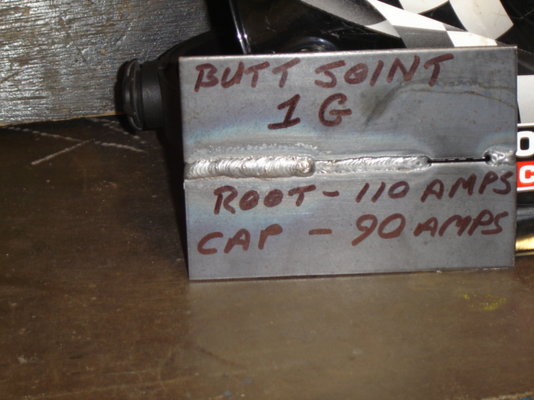

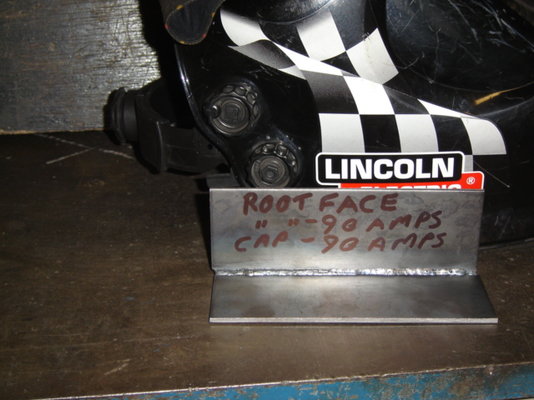

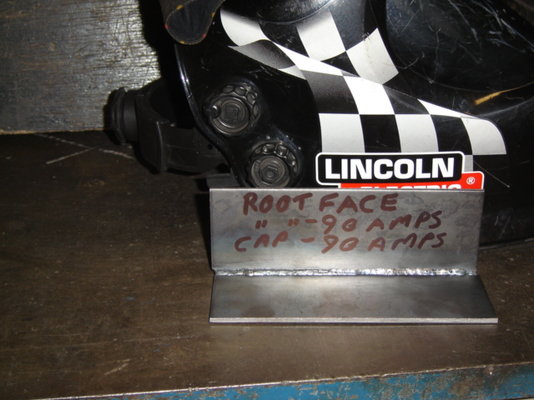

Preparing today for block two session starting very soon. Welding up exemplars with details written on each one, thought it would be a good idea to share around with other budding tiggers.

Plant: Lincoln Electric 3 phase Invertec 305T AC/DC Inverter.

Tungsten: Ceriated 2.4 dia.

Gas: Argon @ 10 LPM.

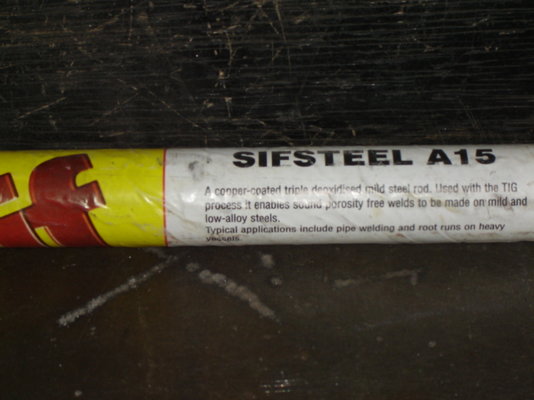

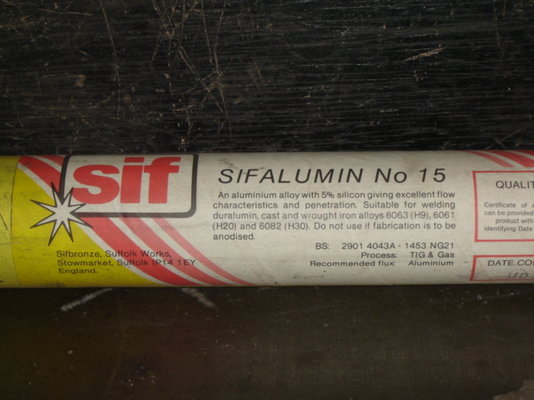

Rods: See pic for spec.

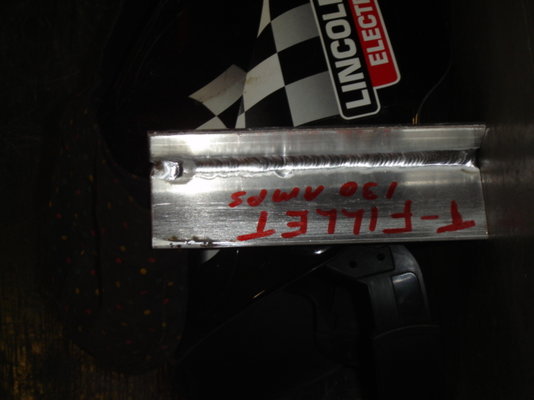

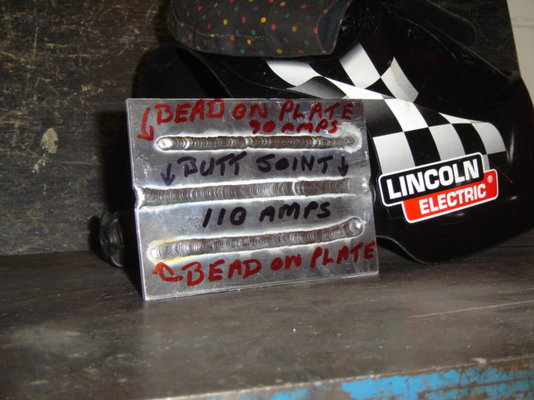

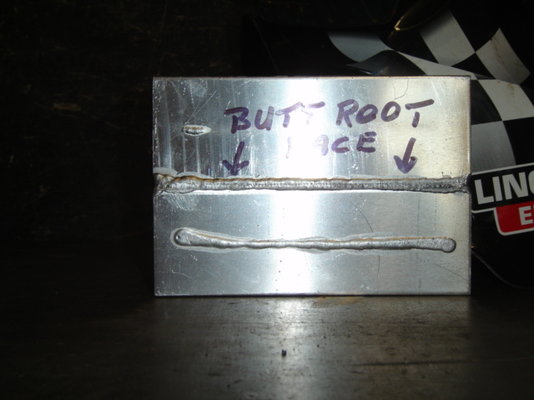

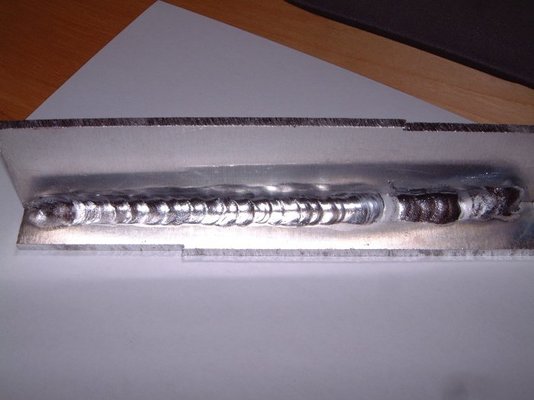

LCS Corner & Butt joints: Root run using 1.6 dia filler, Capped using 2.4 dia. Remainder of LCS joints: 1.6 dia filler rod.

Al/Al: All joints made with single pass using 2.4 dia filler. Butt gapped @ 2.4mm, corner gapped @ 1.5mm. Same for LCS Butt & Corner.

Gaps and amp settings are what I work with, others may do different, all down to preference really!

Malcolm, feel free to tidy up pics and, select/delete using your judgement on picture quality.

Cheers...............

Oops, can only upload ten, more to come........

Plant: Lincoln Electric 3 phase Invertec 305T AC/DC Inverter.

Tungsten: Ceriated 2.4 dia.

Gas: Argon @ 10 LPM.

Rods: See pic for spec.

LCS Corner & Butt joints: Root run using 1.6 dia filler, Capped using 2.4 dia. Remainder of LCS joints: 1.6 dia filler rod.

Al/Al: All joints made with single pass using 2.4 dia filler. Butt gapped @ 2.4mm, corner gapped @ 1.5mm. Same for LCS Butt & Corner.

Gaps and amp settings are what I work with, others may do different, all down to preference really!

Malcolm, feel free to tidy up pics and, select/delete using your judgement on picture quality.

Cheers...............

Oops, can only upload ten, more to come........

-

filler1.JPG129.9 KB · Views: 667

filler1.JPG129.9 KB · Views: 667 -

sample2.JPG143.1 KB · Views: 682

sample2.JPG143.1 KB · Views: 682 -

sample3.JPG143.7 KB · Views: 675

sample3.JPG143.7 KB · Views: 675 -

sample4.JPG155.9 KB · Views: 862

sample4.JPG155.9 KB · Views: 862 -

sample5.JPG147.9 KB · Views: 662

sample5.JPG147.9 KB · Views: 662 -

sample6.JPG122.9 KB · Views: 662

sample6.JPG122.9 KB · Views: 662 -

sample7.JPG142.6 KB · Views: 655

sample7.JPG142.6 KB · Views: 655 -

sample8.JPG144.7 KB · Views: 652

sample8.JPG144.7 KB · Views: 652 -

sample9.JPG153.2 KB · Views: 659

sample9.JPG153.2 KB · Views: 659 -

sample10.JPG158.4 KB · Views: 628

sample10.JPG158.4 KB · Views: 628

, to make things sligthly easier, BigJoe can feed the wire using his BigToe

, to make things sligthly easier, BigJoe can feed the wire using his BigToe

1.707x material thickness?

1.707x material thickness?

Great!!!

Great!!!