You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing - is this viable?

- Thread starter rtcosic

- Start date

Dev

8th generation, Weyland type

- Messages

- 1,405

Hold hard there! Did you just draw and render that??

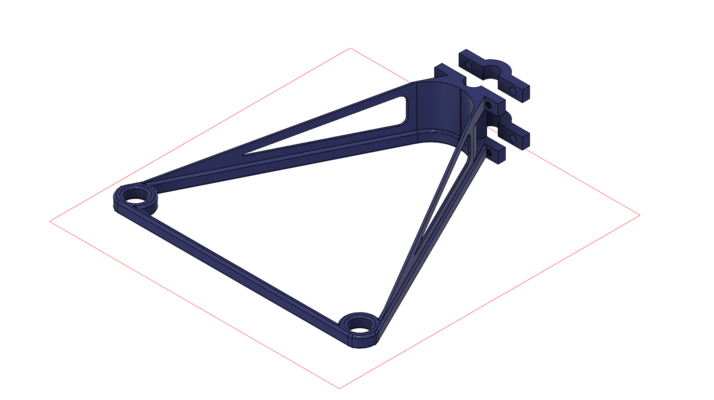

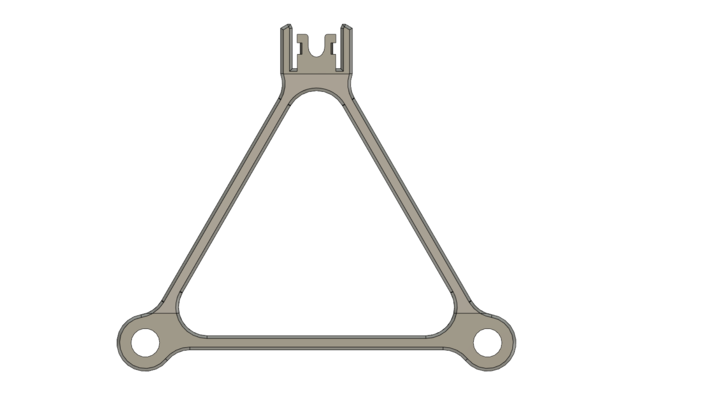

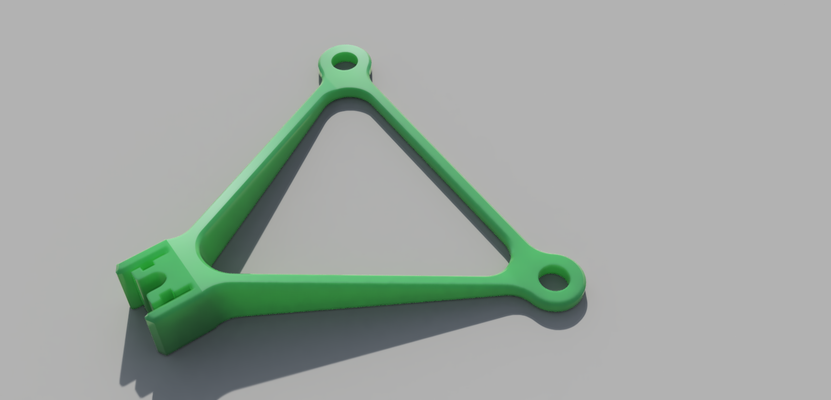

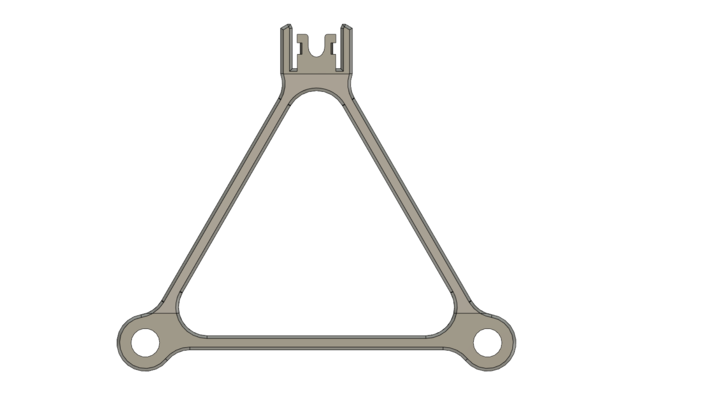

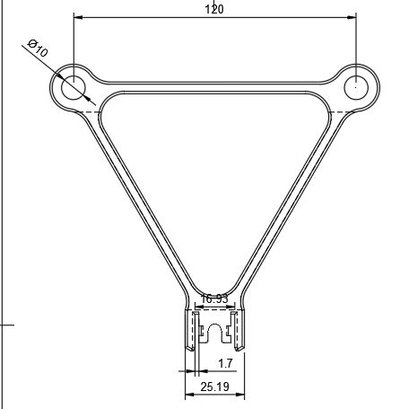

yeah that’s a quick model based on your photo and a couple of assumptions - estimated the distance between the eyes as 120mm and the eyes themselves are 9mm, I think, maybe 10 - I can’t remember and I don’t have it front of me.

I've never seen one in the flesh - do you actually have one?

No, just pinched the pic from

http://passapcanada.com/

spares link

https://sewknit.ca/knitting-machines/passap/passap_machine_parts

tflnemesis

Member

- Messages

- 649

If you are wanting strength PETG is the filament to print them in.

I have had quite a bit of success copying plastic parts and printing new, mate of mine has all new window hinges and catches in his caravan printed by me. Just a shame all I had was red PETG .

.

I could fab that up in fusion and have it printing within a couple of hours easy. The main problem will be getting the measurements right, but thats easy enough if you have a complete original.

I have had quite a bit of success copying plastic parts and printing new, mate of mine has all new window hinges and catches in his caravan printed by me. Just a shame all I had was red PETG

.

.I could fab that up in fusion and have it printing within a couple of hours easy. The main problem will be getting the measurements right, but thats easy enough if you have a complete original.

mike os

just a little insane.....

- Messages

- 9,652

- Location

- North Wales

Mainly titanium... but also some copper when thermal conductivity is not the prime concernWhat metal do you print with?

Impressive...Mainly titanium... but also some copper when thermal conductivity is not the prime concern

rtcosic

Forum Supporter

- Messages

- 3,011

- Location

- Warwickshire

No, just pinched the pic from

http://passapcanada.com/

spares link

https://sewknit.ca/knitting-machines/passap/passap_machine_parts

The Passap machines were very popular in Canada and there was a world-renowned specialist there who has since retired.

That spares supplier's website is a little misleading. It lists every spare part originally on Passap's parts list. But when you look at the individual item many are 'out of stock' despite displaying a price.

yeah that’s a quick model based on your photo and a couple of assumptions - estimated the distance between the eyes as 120mm and the eyes themselves are 9mm, I think, maybe 10 - I can’t remember and I don’t have it front of me.

If I measure the item more accurately would you refine the drawing?

mike os

just a little insane.....

- Messages

- 9,652

- Location

- North Wales

You don't want to see the invoicesImpressive...

rtcosic

Forum Supporter

- Messages

- 3,011

- Location

- Warwickshire

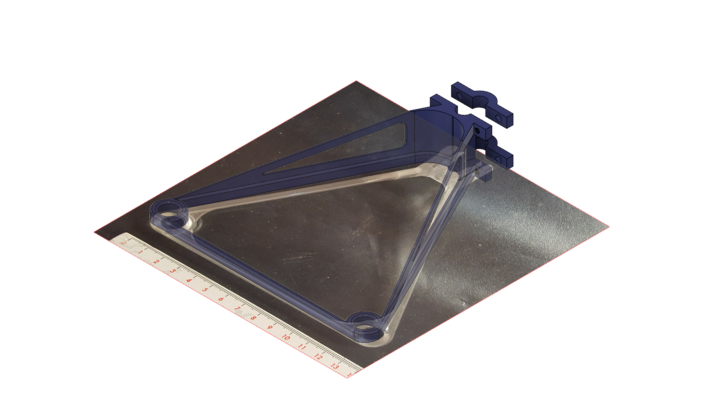

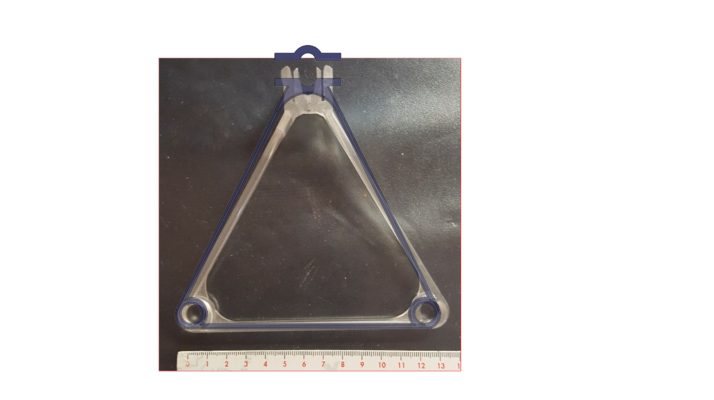

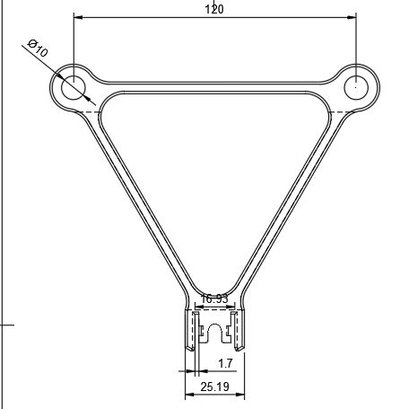

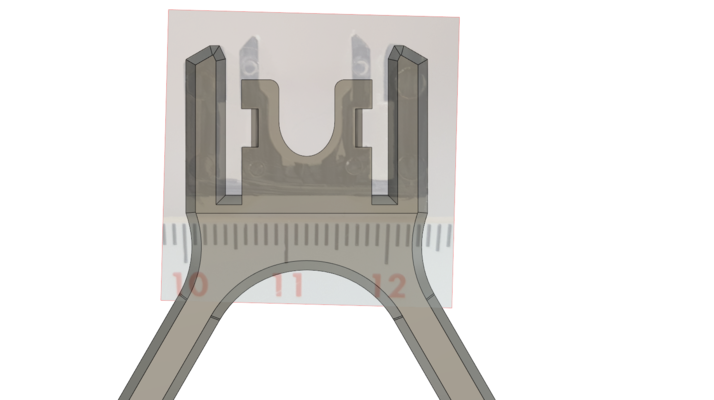

Some Photographs and my effort at a dimensioned SketchUp drawing:

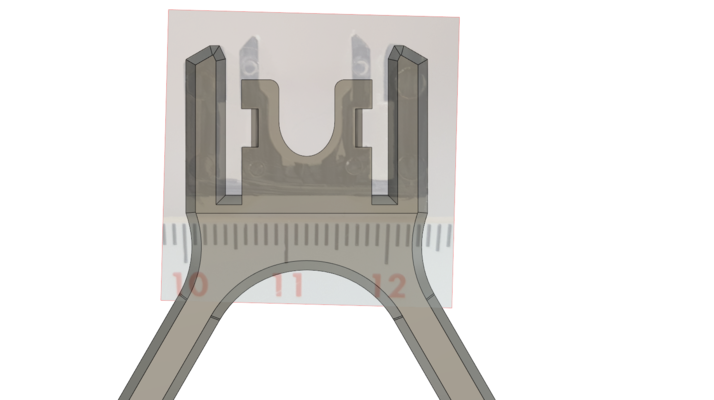

Cross Section. Black marker on clear plastic, looking at the underside:

View media item 10948

The Mast. A U shaped extrusion c. 1.2 mm thick. Pressed lips to engage in the slot on the plastic:

View media item 10949

A loose cable runs inside the extrusion :

View media item 10947

An attempt at dimensioned drawing:

View media item 10952

The slots to engage with the lips is 18mm deep measured from the bottom. The centre line of the legs is also at 18mm from the bottom. The triangulation runs underneath.

Measure yourself thusly, PM an address and a jumper may appear as if by magic:

View media item 10951

Cross Section. Black marker on clear plastic, looking at the underside:

View media item 10948

The Mast. A U shaped extrusion c. 1.2 mm thick. Pressed lips to engage in the slot on the plastic:

View media item 10949

A loose cable runs inside the extrusion :

View media item 10947

An attempt at dimensioned drawing:

View media item 10952

The slots to engage with the lips is 18mm deep measured from the bottom. The centre line of the legs is also at 18mm from the bottom. The triangulation runs underneath.

Measure yourself thusly, PM an address and a jumper may appear as if by magic:

View media item 10951

I bet I don't..lolYou don't want to see the invoices

Dev

8th generation, Weyland type

- Messages

- 1,405

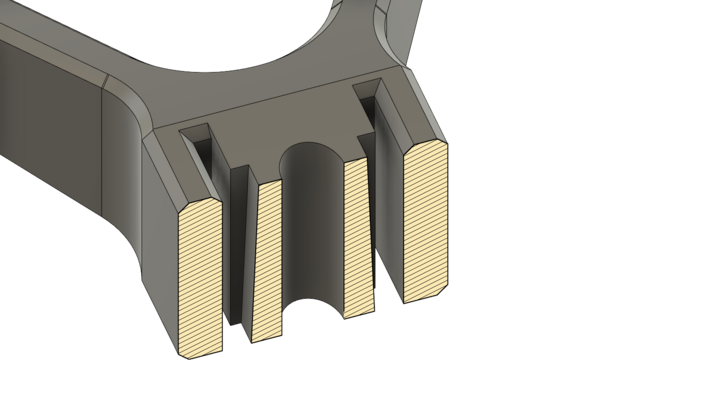

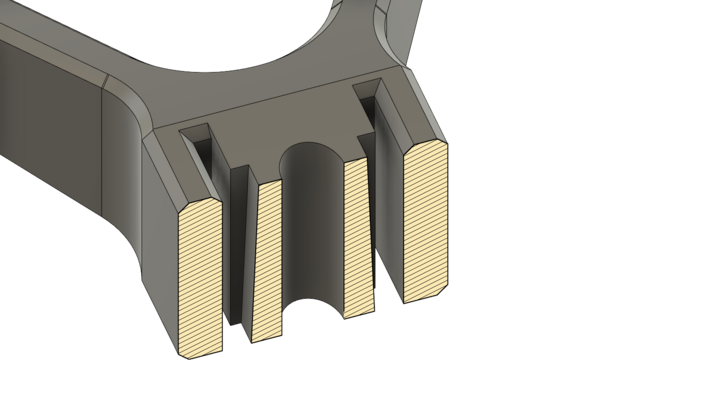

Alright here's an attempt - The weakness is still the internal clamp but I've made it thicker, hopefully the cable still fits. If it were me I'd do away with holding it internally and clamp on the outside of the mast - less elegant, but less fragile too. I've made the gap 1.7mm but put a 2 degree taper on the inside of the part that makes with the lugs. What do you reckon?

rtcosic

Forum Supporter

- Messages

- 3,011

- Location

- Warwickshire

The originals break their 'arms' due to 'impact damage' - they get knocked about when moving the machine, walking past it etc. They are also over 30 years old and UV gets to them eventually even indoors.

They don't fail due to any in-service loads.

They don't fail due to any in-service loads.

rtcosic

Forum Supporter

- Messages

- 3,011

- Location

- Warwickshire

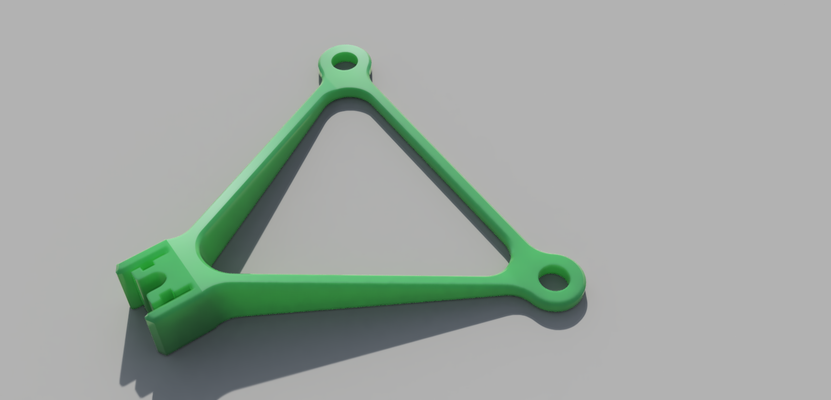

The slots should be 'blind' and be about 18mm long with about a 10mm closed length to sit on the projections in the mast, but the printed arms are an 'interference' fit, aren't under any material load other than their own weight so.......................

View media item 10966

they work fine!

Happy SWMBO, except having washed the jumper - as is normal - it's shrunk. It's quietly 'resting' with a little tension on it to try to persuade it back to the planned dimensions. The knitting equivalent of percussive persuasion of a distorted weldment.

Edit: didn't 'proofread' the photo - the clever phone has focussed on the wrong yarn guide.

View media item 10966

they work fine!

Happy SWMBO, except having washed the jumper - as is normal - it's shrunk. It's quietly 'resting' with a little tension on it to try to persuade it back to the planned dimensions. The knitting equivalent of percussive persuasion of a distorted weldment.

Edit: didn't 'proofread' the photo - the clever phone has focussed on the wrong yarn guide.