Ratty

Putting the She in Sheds

- Messages

- 1,775

Ok folks, found a little time last night to try out the welder (and my ability to weld with a mig! first time since my 2 day course so be gentle) on some 1.5mm plate. Managed a few reasonable straight welds on the flat so tried some fillet welds (is that the right term?)

I can't work out how to put text under each pic so here is the explanation..

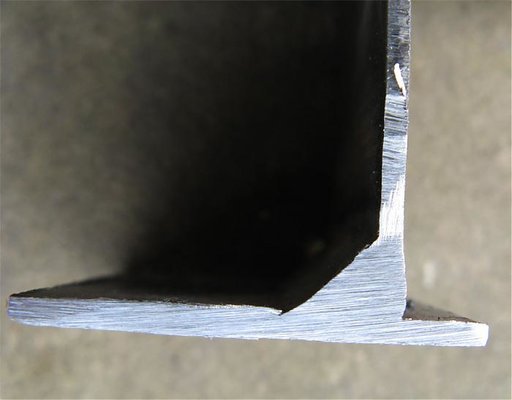

1. Three short runs (1, 2, 3,) which didn't join up too well but looked ok I thought till I turned the piece round and found none had really penetrated..(2)

3. Had another go with the dial cranked up, again the reverse side not so impressive (4) first had a huge blob of weld on the other side and second blew a hole. Think I was moving too slowly as 3rd and 4th were better and achieved some penetration tho' still patchy.

I'm a bit in the dark about what sort of gas flow I'm getting, the reg has no gauge (and the near invisible lines are in PSI and not LPM - anyone know how to convert?) and the one on the argomiser (also in psi) didn't appear to be working. (see pics in my thread 'Gauges') although I later discovered it was when I used the argomiser key to turn up the flow.

Talked to weldequip as I was about to buy a new set of gauges and reg to replace the ancient set-up on the bottle and he talked himself out of a sale! Thanks for your advice and time w'eq, much appreciated. I shall persevere with what I have until I understand how it works.

Anyway, any feedback much appreciated and if anyone knows anything about argomisers and what they should be set at for max benefit please let me know!

and if anyone knows anything about argomisers and what they should be set at for max benefit please let me know!

I can't work out how to put text under each pic so here is the explanation..

1. Three short runs (1, 2, 3,) which didn't join up too well but looked ok I thought till I turned the piece round and found none had really penetrated..(2)

3. Had another go with the dial cranked up, again the reverse side not so impressive (4) first had a huge blob of weld on the other side and second blew a hole. Think I was moving too slowly as 3rd and 4th were better and achieved some penetration tho' still patchy.

I'm a bit in the dark about what sort of gas flow I'm getting, the reg has no gauge (and the near invisible lines are in PSI and not LPM - anyone know how to convert?) and the one on the argomiser (also in psi) didn't appear to be working. (see pics in my thread 'Gauges') although I later discovered it was when I used the argomiser key to turn up the flow.

Talked to weldequip as I was about to buy a new set of gauges and reg to replace the ancient set-up on the bottle and he talked himself out of a sale! Thanks for your advice and time w'eq, much appreciated. I shall persevere with what I have until I understand how it works.

Anyway, any feedback much appreciated

and if anyone knows anything about argomisers and what they should be set at for max benefit please let me know!

and if anyone knows anything about argomisers and what they should be set at for max benefit please let me know!

No worries! I've decided I'm going to make learning the migatronic - and how to mig weld - my route to working out what it is I actually need - more power or less..would tig be better..shall I go for 3 ph..where will I be using it most (i.e. if I need to install 3 ph sockets the best place top put them) etc. Then if I want to sell it in a few months and upgrade I will have some knowledge of it and can sell with a clear conscience.

No worries! I've decided I'm going to make learning the migatronic - and how to mig weld - my route to working out what it is I actually need - more power or less..would tig be better..shall I go for 3 ph..where will I be using it most (i.e. if I need to install 3 ph sockets the best place top put them) etc. Then if I want to sell it in a few months and upgrade I will have some knowledge of it and can sell with a clear conscience.

I think it's my apple sulking. I'll try again later..off to eat

I think it's my apple sulking. I'll try again later..off to eat

you will be able to do overhead and other positional welding, nae tother a baw. Play with the amps and speed feeds and your laughing.

you will be able to do overhead and other positional welding, nae tother a baw. Play with the amps and speed feeds and your laughing.