Got a reasonably sized job coming up, for which I can justify a new welder (involves walking to site with kit, so want a smaller, lighter welder). Does anyone have any experience with a dual voltage welder? Like https://www.weldingsuppliesdirect.c...xts-163-dual-voltage-mma-welding-machine.html is there any reason not to go for a dual voltage machine - I do a fair bit of site work, so not everywhere has easy access to 240v, and some sites don't allow 240v at all. However, I have always managed before, so it isn't a deal breaker either way, I just thought it might add some flexibility for me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

110v welder

- Thread starter Osu817

- Start date

Tom Orrow L

Member

- Messages

- 2,781

- Location

- Shropshire, UK

Hi  There's no disadvantage to getting a dual voltage welder. Just remember that if you have a lower input voltage you'll need a higher input current i.e. the Parweld XTS 163 DV you linked will run on a 16A 230V plug but if you switch to 110V you'll need to stick it on a 32A supply. Also, most dual voltage machines will have a limited output on 110V. Usually you'll be able to run a 3.2MM electrode on it though.

There's no disadvantage to getting a dual voltage welder. Just remember that if you have a lower input voltage you'll need a higher input current i.e. the Parweld XTS 163 DV you linked will run on a 16A 230V plug but if you switch to 110V you'll need to stick it on a 32A supply. Also, most dual voltage machines will have a limited output on 110V. Usually you'll be able to run a 3.2MM electrode on it though.

If you do decide to go for that unit use coupon code PARWELD10 for 10% off

There's no disadvantage to getting a dual voltage welder. Just remember that if you have a lower input voltage you'll need a higher input current i.e. the Parweld XTS 163 DV you linked will run on a 16A 230V plug but if you switch to 110V you'll need to stick it on a 32A supply. Also, most dual voltage machines will have a limited output on 110V. Usually you'll be able to run a 3.2MM electrode on it though.

There's no disadvantage to getting a dual voltage welder. Just remember that if you have a lower input voltage you'll need a higher input current i.e. the Parweld XTS 163 DV you linked will run on a 16A 230V plug but if you switch to 110V you'll need to stick it on a 32A supply. Also, most dual voltage machines will have a limited output on 110V. Usually you'll be able to run a 3.2MM electrode on it though.If you do decide to go for that unit use coupon code PARWELD10 for 10% off

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,653

- Location

- Southampton

There usually is at least one disadvantage to a dual voltage machine. Most will have less output on 110v input than a dedicated 110v only mma inverter.

A Kemppi Minarc 151 and a few other dedicated 110 volt only inverters can achieve 150 amp output. Most of the other dual voltage units are between 110 and 120 amp output. This is sometimes not enough to run a 3.25 rod, especially when you factor in voltage drop from long extension leads which will reduce the inverters performance still further.

Check the efficiency of whatever machine you buy, and take note of what the output drops down to when powered from a 110v supply.

The Parweld 163DV does have 140 amp output on 110v input but there are plenty of others that don’t. Bear in mind it will be drawing all of 32 amps to achieve that so 4mm2 extension leads and decent 5 kva transformers will be a necessity if you want to go long distances from the wall socket.

A Kemppi Minarc 151 and a few other dedicated 110 volt only inverters can achieve 150 amp output. Most of the other dual voltage units are between 110 and 120 amp output. This is sometimes not enough to run a 3.25 rod, especially when you factor in voltage drop from long extension leads which will reduce the inverters performance still further.

Check the efficiency of whatever machine you buy, and take note of what the output drops down to when powered from a 110v supply.

The Parweld 163DV does have 140 amp output on 110v input but there are plenty of others that don’t. Bear in mind it will be drawing all of 32 amps to achieve that so 4mm2 extension leads and decent 5 kva transformers will be a necessity if you want to go long distances from the wall socket.

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,653

- Location

- Southampton

I don’t by any means class that Parweld 163DV as Industial grade. I’ve just run three 3.25mm 6013s back to back testing a machine replaced under warranty and the mains lead and the supplied stick and earth cables are hot to the touch. Everything about the machine is costed down to the bare minimum. I’d shudder to think what they would feel like after half a packet of rods has been run. Take from that what you will.

Ubique

Member

- Messages

- 2,473

- Location

- East Midlands

That's shocking. How has that got any kind of certification with such a basic error?

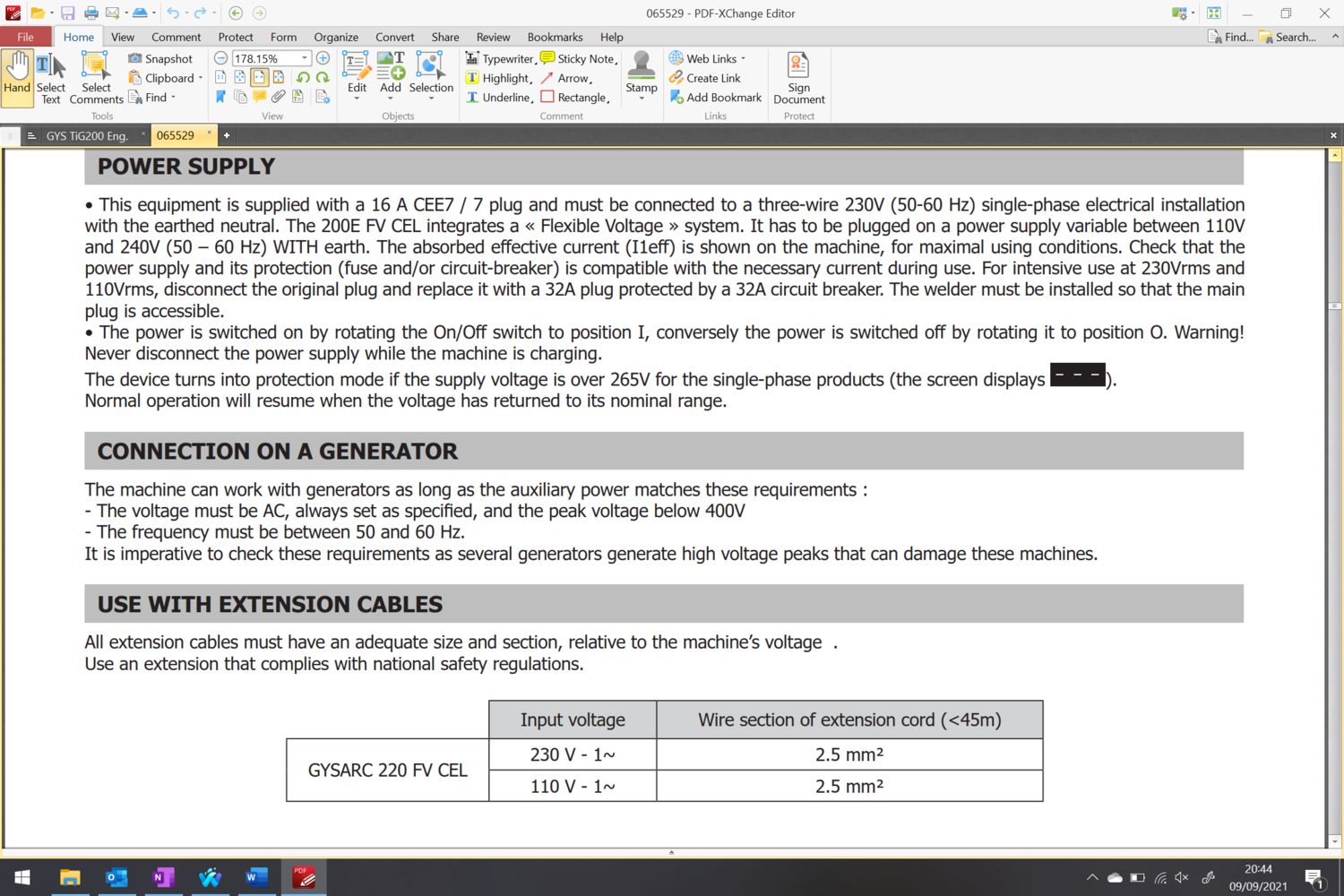

ETA - a page from GYSARC 220 FV CEL The machine is fitted with 2.5mm HO7RN-F

That's the one a mate of mine throws in the back of his LR for site jobs, along with a selection of extension cables.

ETA - a page from GYSARC 220 FV CEL The machine is fitted with 2.5mm HO7RN-F

That's the one a mate of mine throws in the back of his LR for site jobs, along with a selection of extension cables.

Ubique

Member

- Messages

- 2,473

- Location

- East Midlands

That's why I avoided using those letters, easily confused with 'China Export'. Proper Certification - for example UL, ASTA, ENEC etc. the LVD is (IMO) pointless. Even the Kitemark is making a comeback, although IIRC, only for cables at the moment.

Munkul

Jack of some trades, Master of none

- Messages

- 7,758

- Location

- Cumbria

We love our lorch micorstick at work. Got 3 QR leads for it that plug straight into the unit, 110v 16a and 32a, and 240v 16a. Gets used quite a bit around site. Just a pain when some of the fixed transformers are under 2kw I think, so they don't run 3.2s without tripping. A good transformer will run 3.2s on the 16a lead just fine.

Tom Orrow L

Member

- Messages

- 2,781

- Location

- Shropshire, UK

Aye, I’d agree with Jim. It’s certainly not industrial grade. My personal choice is the GYS E200FV MMA.

Many thanks for all your help and knowledge. I will have a think about which way I want to go - probably just going to stick with 240v for the time being: I don't generally trust other people's extension leads etc, so having to add a 5kva transformer to my kit defeats the light weight options of these smaller MMA units. Good to know what I am looking at if I need to get a 110v in the future though.