Cris B

Every day welding is a school day

- Messages

- 512

- Location

- Sefton

Cheers Chipper.

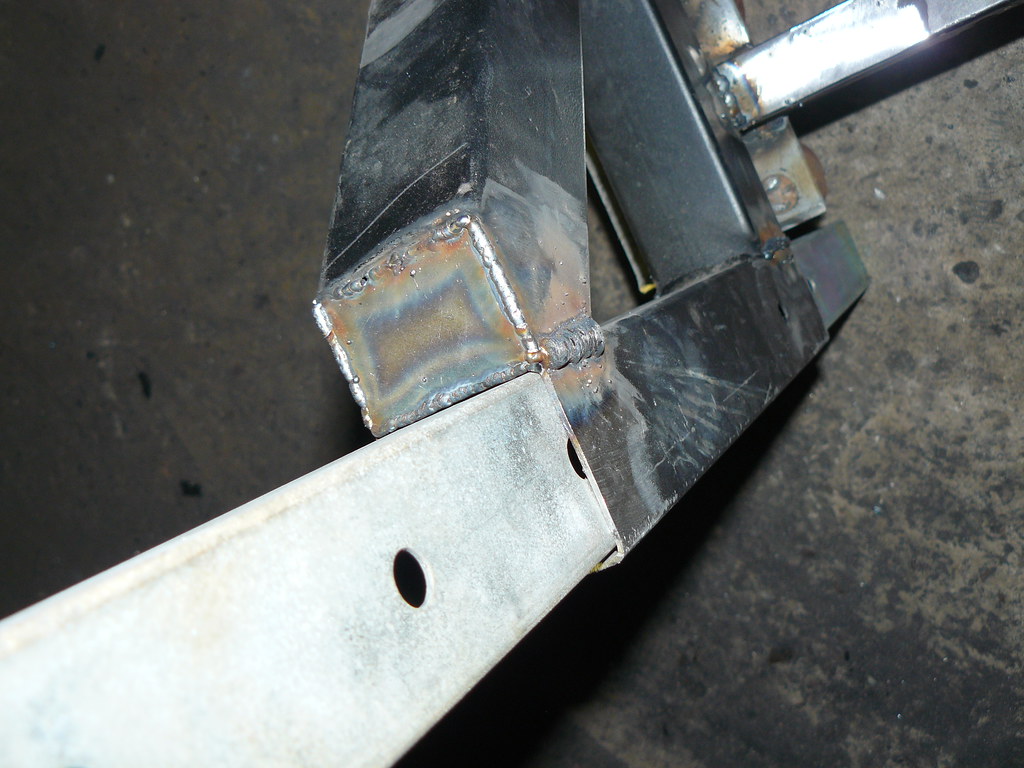

Managed a few more hours his afternoon on the car. Using cardboard I templated repairs sections for the internal chassis rail gusset and then the chassis rail top. I’ll let the photos do the talking…

Still plenty of work to do in getting these to a stage where they can be fitted to the car.

Managed a few more hours his afternoon on the car. Using cardboard I templated repairs sections for the internal chassis rail gusset and then the chassis rail top. I’ll let the photos do the talking…

Still plenty of work to do in getting these to a stage where they can be fitted to the car.

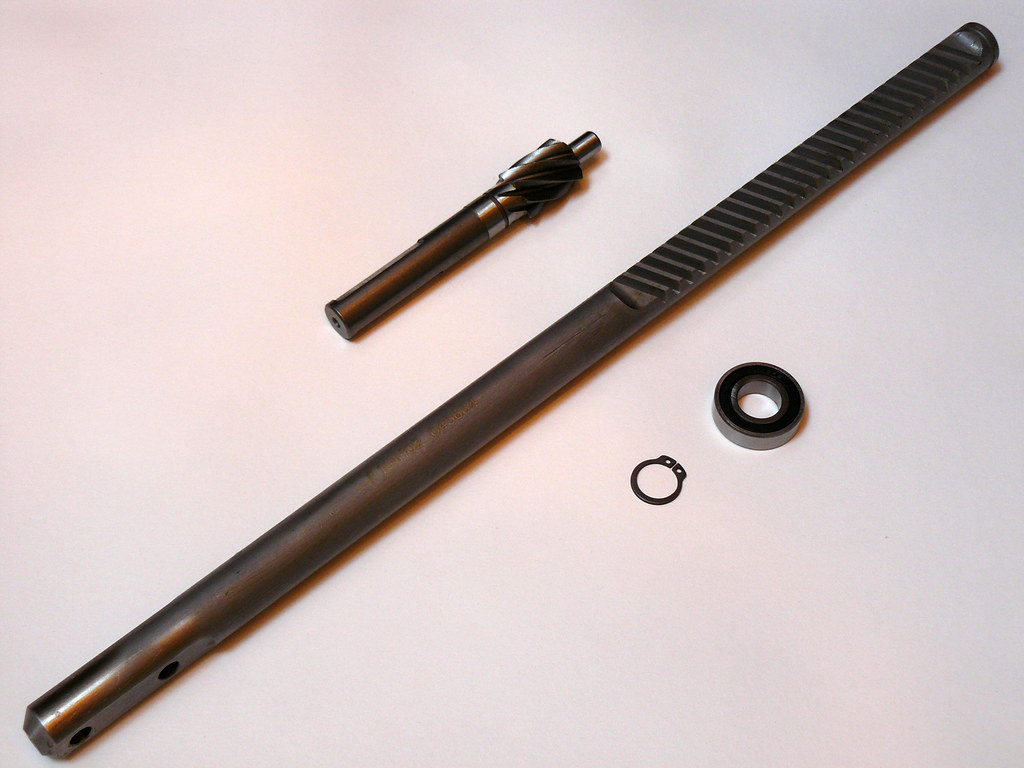

I hope it isn't as bad as it looks...

I hope it isn't as bad as it looks...