You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

tig, mig, stick most penotration?

- Thread starter brendan h

- Start date

From my expierence (in order from the deepest penetration to the lowest...) for the mild steel base material:

1) spray MIG,

2) flux cored gas shielded MIG,

3) gasless MIG,

4) 6011,

5) TIG with some normal amperage settings,

6) 6013,

7) short arc MIG,

Maybe I am wrong somewhere so I would be glad to be corrected...

1) spray MIG,

2) flux cored gas shielded MIG,

3) gasless MIG,

4) 6011,

5) TIG with some normal amperage settings,

6) 6013,

7) short arc MIG,

Maybe I am wrong somewhere so I would be glad to be corrected...

- Messages

- 6,309

impossible to anwser really especially as one of those process should be in volts instead of amps...

Flux cored improves MIG pen volt for volt.

and a 6011 will pen more than a 6013, but its made for stoving not everyday use.......

TIGs a clean controlled weld, and can be very controlled to pen just right through the joint...

A skilled operator makes the process work for them...

Flux cored improves MIG pen volt for volt.

and a 6011 will pen more than a 6013, but its made for stoving not everyday use.......

TIGs a clean controlled weld, and can be very controlled to pen just right through the joint...

A skilled operator makes the process work for them...

- Messages

- 6,309

sorry but what is stoving?

and why is mig used in volts and not amps?

stoving is a positional pipe weld, Its a term used by old boiler makers (hence stove) but pipe welders nicked the technique, Its basically down hand welding, cellulose rods (6011) are used to achieve pen.....

MIG is constant voltage rather than amps, when you adjust a plant you change the OCV (volts), the amps will change with the wire speed and wire type size etc.....

- Messages

- 6,309

Is there a thread anywhere, where we are given a definition and a use for different types of rods, such as "cellulose rods (6011)" "are used to achieve pen(etration)"

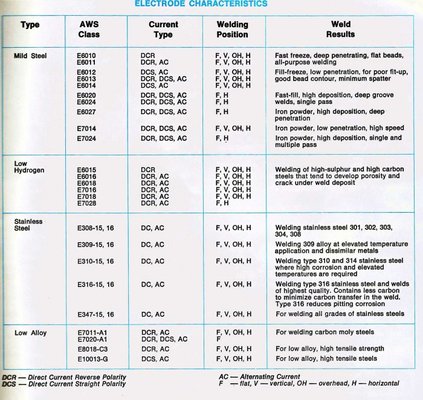

I have a chart of all the basics "not just basic electrodes BTW", I could copy and paste if that'l be any help....

madkayaker

Pro sparkey Pro Welder

- Messages

- 13,655

Please Snowy