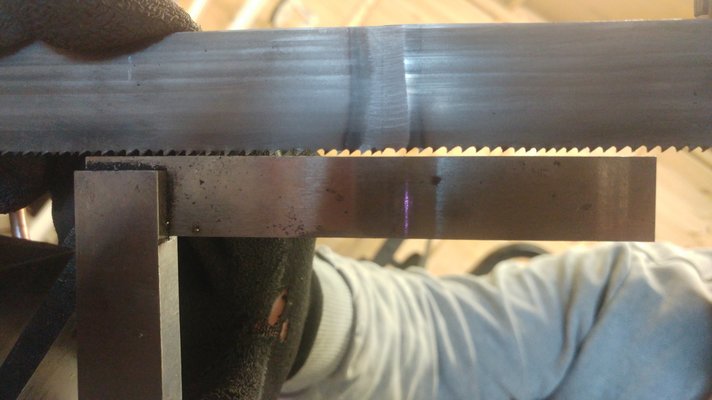

Well of course i grant you only the op knows how much he will be using the saw. But mild steel will not wear at all well if the saw is used reasonable regularly. It will get swarf dragged via the guide and will prematurely wear, good guides are vital to a saw that cuts well as i'm sure you know. Experience tells me machines always bugger you about when you least need them to bugger you about and when you have deadlines to meet. In this case go to use it and he will be getting horrible troublesome cuts then you have to mess about making a new soft guide that will fail again. I would rather make it right once every 5 years than make it wrong 5 times every year, just my personal preference.

Looking at that other thread about this saw it looks like a guide body and brazed in carbide insert, which would not be that expensive to get made by a wire cutters (if you know which ones to use) Make the body out of BDMS and use Gauge plate drilled and tapped insert hardened it and leave fully hard for this application or as said get a carbide one cut, done for life then. May even be able to get one of the shelf if he knows who made the saw.

Looking at that other thread about this saw it looks like a guide body and brazed in carbide insert, which would not be that expensive to get made by a wire cutters (if you know which ones to use) Make the body out of BDMS and use Gauge plate drilled and tapped insert hardened it and leave fully hard for this application or as said get a carbide one cut, done for life then. May even be able to get one of the shelf if he knows who made the saw.