Ali

Member

- Messages

- 1,939

- Location

- Cheshire

Hi Guys,

A member on a motorcycle forum I use has been building a seriously cool 'prism' type chopper tank, and is having some problems. I told him how helpful you lot are and he's asked me to call on your advice .

.

I won't post a link to the other forum as I'm not sure about the rules here on links.

Anyway, here's what he's building:

The sheet metal part goes to plan. He has the steel folded up by someone with a press brake, then tacks it together:

Then welds up the seams:

Then he carefully cuts out a channel in the base of the tank, and fits a tunnel so that the tank sits correctly on the backbone of the bike frame. To make the tunnel, he's built this extremely nifty tool:

Awesome.

The tunnel then gets fitted & welded in:

Here's a close up of his Tig skills - he says he's a beginner, but he knows what he's doing...

So far, despite all odds there hasn't been any major issues with the sheet metal, which I believe he has welded without filler. NOW the problems.

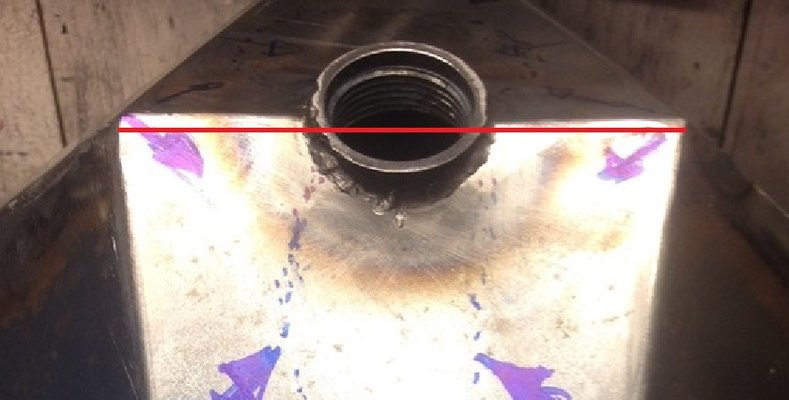

A filler neck needs to be fitted to the tank - got to get fuel in there somehow, right? This is a threaded tube, not sure the dimensions, but we're probably talking about a wall thickness of 3-5mm looking at the pictures. This requires a little more heat to weld in, which is where the shrinkage occurs to the sheet metal.

He admits he went for it a little on this bit, as it was going well.

Here is the shrinkage:

A member on a motorcycle forum I use has been building a seriously cool 'prism' type chopper tank, and is having some problems. I told him how helpful you lot are and he's asked me to call on your advice

.

.I won't post a link to the other forum as I'm not sure about the rules here on links.

Anyway, here's what he's building:

The sheet metal part goes to plan. He has the steel folded up by someone with a press brake, then tacks it together:

Then welds up the seams:

Then he carefully cuts out a channel in the base of the tank, and fits a tunnel so that the tank sits correctly on the backbone of the bike frame. To make the tunnel, he's built this extremely nifty tool:

Awesome.

The tunnel then gets fitted & welded in:

Here's a close up of his Tig skills - he says he's a beginner, but he knows what he's doing...

So far, despite all odds there hasn't been any major issues with the sheet metal, which I believe he has welded without filler. NOW the problems.

A filler neck needs to be fitted to the tank - got to get fuel in there somehow, right? This is a threaded tube, not sure the dimensions, but we're probably talking about a wall thickness of 3-5mm looking at the pictures. This requires a little more heat to weld in, which is where the shrinkage occurs to the sheet metal.

He admits he went for it a little on this bit, as it was going well.

Here is the shrinkage:

whether it was leaded carbon steel or 303 stainless which has a load of sulphur in it. A fairly common way to deal with their nastyness it turn the juice up a bit and stuff more wire in there to combat their tendancy to uncut. If he did that...

whether it was leaded carbon steel or 303 stainless which has a load of sulphur in it. A fairly common way to deal with their nastyness it turn the juice up a bit and stuff more wire in there to combat their tendancy to uncut. If he did that...