Maker

Most folk just call me; Orange Joe

- Messages

- 10,640

- Location

- Keeler crater

This stuff? It's to be worth a shot for the price.

Would petrol do, I've got some of that.A drop of diesel can work too.

I could get some of this tomorrow. If it doesn't work as a lubricant, I could set fire to it to heat it up.

I think I've got an empty of 3 in 1 kicking about. As for heating I've got an electric heat gun and a stupid little Dremel blow torch. Are torches available that fit onto big propane tanks?(13KG type things)I like to have some in an ex '3 in 1' oil can for dribbling onto seized parts.

Heat is usually the answer btw, don't tell me you don't have a heat source in your workshop?

Btw, you asked about brokenbiker - he left, I can't remember why

.

.That's often what happens regardless, if/when it was caused when joining the chain sometimes the outer plates/links will bend far enough for the chain to come apart (or jam things before it lets go completely when the bike has gears), sometimes the damage caused when a pin is forced in results in the chain snapping. If yours let go with a cleanish break nowhere near the pin holes in the outer or inner plates then small, worn sprockets and not enough slack for the chain to skip is probably the causeWhenever the chain broke, it wasn't that a pin came out and separated the chain, the actual link snapped between the pins.

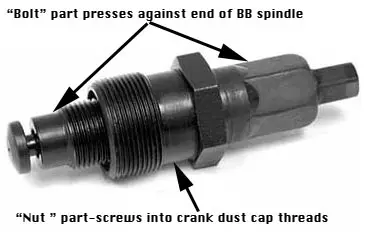

With you, the business end of many crank extractors is a bit mickey mouse in this respect as are the adaptor bushings for different styles of BB spindle. I used to make my own, either a top hat slug to drop into the end of the crank or modify a spare bolt by grinding it's head down. The modified bolt trick only works properly if the extra has a free moving bushing in the end like this styleIt's a steel crank on a steel 48 spline axle. The extraction thread on the crank is fine, it's the bolt hole in the axle that's knackered, the end of the crank puller is only a little bit bigger than the bolt so it pressed its way into the hole and pulled the threads off for the first few mm, leaving a great big burr inside. I'll try heat today hopefully. There isn't a spider on it, it's only a 28 tooth sprocket so it fits directly on. There's no way it's coming off with the crank arms on. It's a 2 piece crank so the crank arm on the sprocket side is permanently attached to the axle. It's the other crank arm that's now stuck so if I make some kind of puller ring, it won't be in the way of anything.

That's the thing I'm after, I'll ask my dad if he knows of one stashed away somewhere. I've got everything but oxygen now (hoses, regulators, flashback arrestors and torches) but in all honesty, I'm scared of trying it out by myself.

Sounds like I'm right to be scared then. I wasn't planning on using it without someone experienced showing me how, I may as well just sell it though.

The top hat thing in that pic is the adaptor for octalink bottom brackets, for the Park tools extractor above it the button in the end is swapped for different sizes. Personally i'd be trying to clean up the end of the BB axle as mentioned earlier and then making a sleeve/bushing to give it something solid to bear against. Plenty of plusgas etc in the meantime and then see if it moves without needing stupid amounts of heaving. If it doesn't then it's time for some heatThe second one is exactly the one I've got, the bit on the end is the same size as the bolt from the bike so it worked its way down the hole.