BrokenBiker

Member

- Messages

- 12,510

- Location

- Newport, South Wales

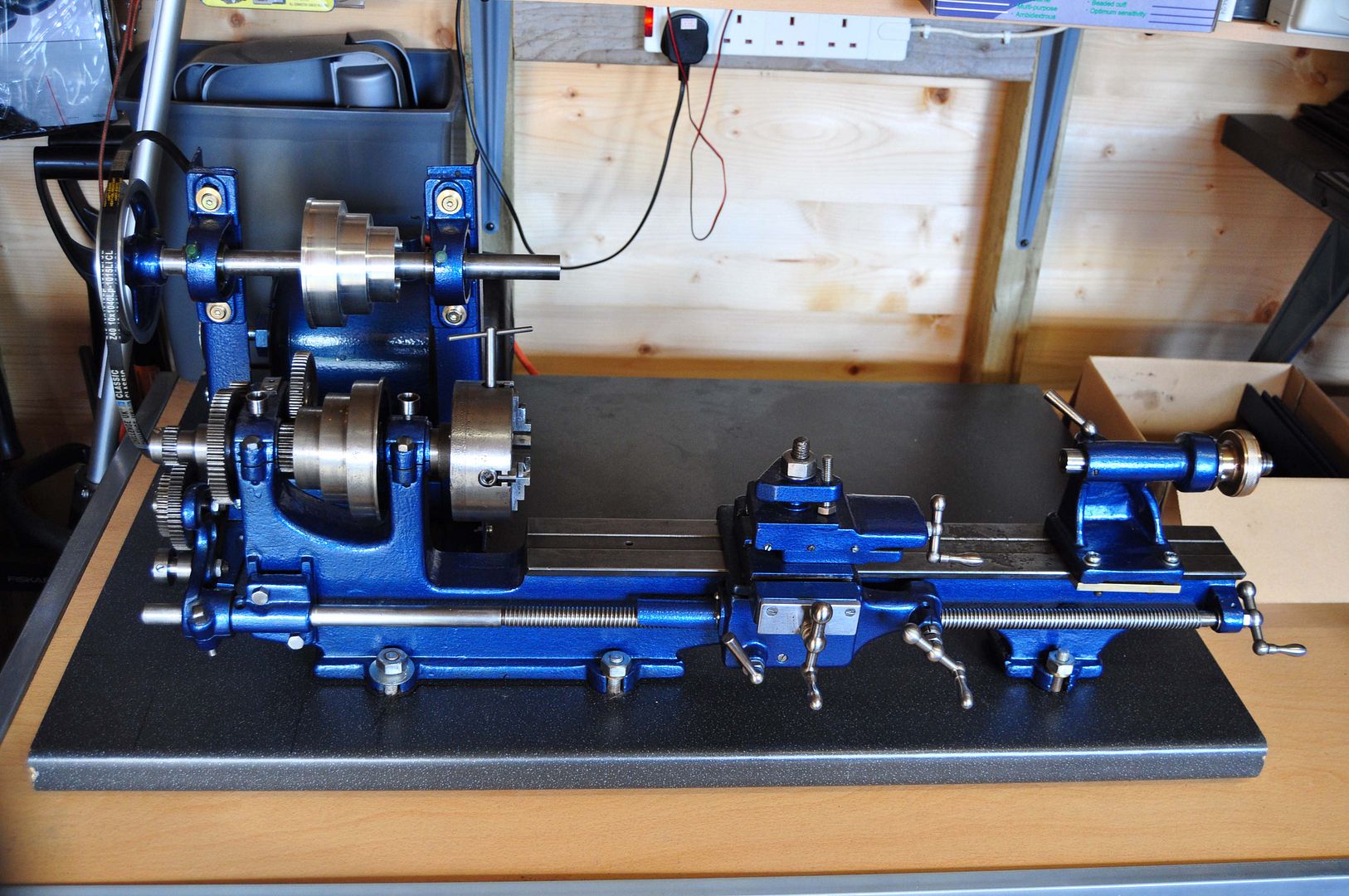

right, granted it has taken me a while since collecting the RandA lathe from cyberprog, but I am now in a position to get it going properly, however ive run into problems.

I have had it running using the old belts, but they are now too far gone to be repaired. I bought new belts when I got the lathe but have only just put them on. its 3 ply flat belt, the same dimensions as the original leather, joined with alligator lacing strips.

now to the problem. if there is any slack at all the motor slips on its belt and the belt starts to burn, the belts have to be seriously tight and if I tension the belts enough that they will spin the chuck, no matter what pulley configuration I use, or back gear, the whole machine vibrates like a cement mixer, and then as soon as I try and put a cut on the chuck stalls and the belts slip again. even on a 2 thou cut on brass.

I am getting really frustrated with this, the machine is mounted on a very heavy wooden table, its more of a job to move the table than it is to move the shed, yet this lathe shakes and rattles it to the point where it moves across the floor.

I have checked all bearings and bushes and everything is like new apart from the grease, which was removed and then replaced with very good quality chain and gear wax.

with the old belts it was ok, I never tried doing any serious turning with it but it did cut and was stable and quiet.

any ideas in what is going wrong here, id like to get it sorted as it looks to be a good little lathe providing I can stop it trying to pull itself off the bench

I have had it running using the old belts, but they are now too far gone to be repaired. I bought new belts when I got the lathe but have only just put them on. its 3 ply flat belt, the same dimensions as the original leather, joined with alligator lacing strips.

now to the problem. if there is any slack at all the motor slips on its belt and the belt starts to burn, the belts have to be seriously tight and if I tension the belts enough that they will spin the chuck, no matter what pulley configuration I use, or back gear, the whole machine vibrates like a cement mixer, and then as soon as I try and put a cut on the chuck stalls and the belts slip again. even on a 2 thou cut on brass.

I am getting really frustrated with this, the machine is mounted on a very heavy wooden table, its more of a job to move the table than it is to move the shed, yet this lathe shakes and rattles it to the point where it moves across the floor.

I have checked all bearings and bushes and everything is like new apart from the grease, which was removed and then replaced with very good quality chain and gear wax.

with the old belts it was ok, I never tried doing any serious turning with it but it did cut and was stable and quiet.

any ideas in what is going wrong here, id like to get it sorted as it looks to be a good little lathe providing I can stop it trying to pull itself off the bench

, but I have plenty of belt left to have another go. I'll probably end up getting one of the thin flat Betalon belts from

, but I have plenty of belt left to have another go. I'll probably end up getting one of the thin flat Betalon belts from  so do some research on it ist

so do some research on it ist