You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

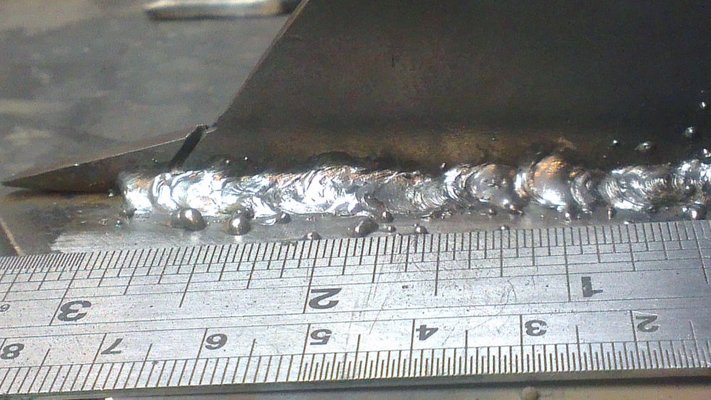

Too much splatter?

- Thread starter cma

- Start date

- Messages

- 14,790

- Location

- UK

Pure C02 is not great - you will get an instant improvement by using such as BOC Argoshield Light.

Weld looks cold and travel speed a bit erratic. Bit of practice will soon put that right.

PS It's spatter, not splatter

Weld looks cold and travel speed a bit erratic. Bit of practice will soon put that right.

PS It's spatter, not splatter

ooopps sorry, cant weld and can't spell either, sorry

Co2 will be staying as I have a huge bottle I use for home brew too so serves dual purpose. Perhaps once it's out I might get some argoshield.

I can't recall the setting I was using at the time. But I recall a bit less wire caused it to go all wrong, so perhaps I need to go up a power setting.

Thanks for the tips.

Co2 will be staying as I have a huge bottle I use for home brew too so serves dual purpose. Perhaps once it's out I might get some argoshield.

I can't recall the setting I was using at the time. But I recall a bit less wire caused it to go all wrong, so perhaps I need to go up a power setting.

Thanks for the tips.

- Messages

- 14,790

- Location

- UK

Try leaving the wire speed as it is and turn the power up a notch. It takes a bit of practice to get the relationship between power, wire feed and travel speed correct. You will probably knacker a few tips trying but it soon becomes second nature.

Tman

Mobile mechanic

- Messages

- 137

- Location

- Durham

Try wire speed on lowest setting then increasing while you weld until the popping stops and you get a sizzling sound. This is how you should set the wire speed on all power settings. Try going up a power or two does look a bit cold. co2 is fine stick with it.

BrokenBiker

Member

- Messages

- 12,739

- Location

- Newport, South Wales

it looks like the weld hasn't sunk into the parent metal, so to speak. Not a great deal of penetration im guessing and maybe lack of fusion in places, but as said above keep at it. Keep playing and try different power settings.When you say "it looks cold" what does that mean? how does a "hot" one look in comparison?

- Messages

- 14,790

- Location

- UK

When you say "it looks cold" what does that mean? how does a "hot" one look in comparison?

Not the best weld pictures, but the only ones on me phone.

Your looking for a smooth, consistent width and throat thickness along the length of the weld, the edges of the weld need to fuse into the parent metal.

Tman

Mobile mechanic

- Messages

- 137

- Location

- Durham

Looks like it is sitting on top of the plate knock up the power a bit and you will see the bead sink deeper into to the plate. It will look a bit flatter as it will have penetrated more into the base metal. This will be a much stronger weld.When you say "it looks cold" what does that mean? how does a "hot" one look in comparison?

Last edited:

pedrobedro

Man at Matalan

- Messages

- 13,089

- Location

- CX near Chesterfield

Too much splatter, lay off the curries  Get your nozzle closer to the work piece and keep it consistent, use both hands to steady the gun.

Get your nozzle closer to the work piece and keep it consistent, use both hands to steady the gun.

Get your nozzle closer to the work piece and keep it consistent, use both hands to steady the gun.

Get your nozzle closer to the work piece and keep it consistent, use both hands to steady the gun.Jan

Member

- Messages

- 881

- Location

- Rotherham, South Yorks

Don't forget that cleanliness of the metal at the point you are welding is just as important - if not more so - than technique. Any rust, oil or paint will prevent full fusion and introduce contaminants to the weld puddle so that it will be weakened.

- Messages

- 14,790

- Location

- UK

Don't forget that cleanliness of the metal at the point you are welding is just as important - if not more so - than technique. Any rust, oil or paint will prevent full fusion and introduce contaminants to the weld puddle so that it will be weakened.

Not always. It is good practice to remove mill scale, grease and dirt before MAG/MIG welding, but in industry, in practice, it rarely happens. Burning through the millscale does 'soak up' some power, but with our 400-500 amp sets it can easily be compensated for. When using a set that is on it's limit for the material thickness being welded, it is essential that the steel is cleaned back to bright.

madkayaker

Pro sparkey Pro Welder

- Messages

- 13,678

Not the best weld pictures, but the only ones on me phone.

Your looking for a smooth, consistent width and throat thickness along the length of the weld, the edges of the weld need to fuse into the parent metal.

View attachment 41700 View attachment 41701

New lorch Paul?

- Messages

- 14,790

- Location

- UK

New lorch Paul?

Not ours. It's a separate wire feed unit on loan.

madkayaker

Pro sparkey Pro Welder

- Messages

- 13,678

Figured it was

Jan

Member

- Messages

- 881

- Location

- Rotherham, South Yorks

Not always. It is good practice to remove mill scale, grease and dirt before MAG/MIG welding, but in industry, in practice, it rarely happens. Burning through the millscale does 'soak up' some power, but with our 400-500 amp sets it can easily be compensated for. When using a set that is on it's limit for the material thickness being welded, it is essential that the steel is cleaned back to bright.

As I suspect that by far the vast majority of hobby only MIGers will have boxes with anything from 150 amps down to possibly 90 amps I think that cleanliness is everything for such as we. Last night I cranked my SIP 130 to warp factor 6 and, with the well cleaned test pieces set well apart, I ran a stitch along a 6" run. Despite the mild steel being around 6mm thick the 0.6 gas wire (keep meaning to get some 0.8 stuff) achieved between 90% & 100% penetration although fusion may not have extended as deep. Had this been an actual welding job with any strain on the joint I would have considered welding up both sides or chamfering the edges first, but it was just an experiment to see what might be possible.

- Messages

- 14,790

- Location

- UK

Anything critical, lifting points etc i would clean the millscale off. The welds do look very much prettier when the millscale has been taken off.