TonyWilk

2-Pint Welder

- Messages

- 114

I've got a MAO's Electric, branded 'Highweld', TIG/Plasma cutter.

Zero info on the plasma cutter in the "manual", but after reading a few posts here (and reducing one tip to slag ) I've happily diced up some 3mm stainless and it seems to work just fine.

) I've happily diced up some 3mm stainless and it seems to work just fine.

Then, after reading several other posts on here, I got a bit confused... should the tip be in constant contact with the piece you are cutting ?

Since my torch has one connection to (-)/air, a 2-pin connection for the switch and the return (+) clipped on the piece, I guess it has to be in contact to work.

In practice that seems the case... have I got it right or am I missing something ?

Yours,

Tony Wilk

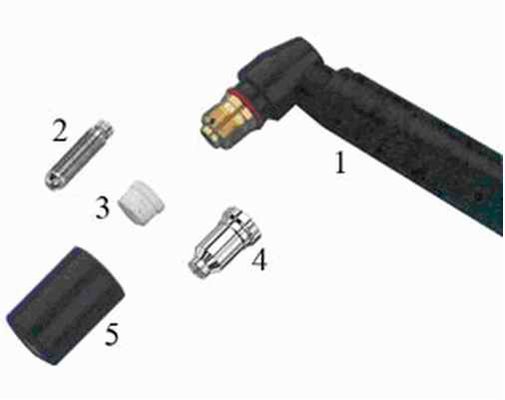

I believe the torch is an "SG-51" type with bits that look like this:

Zero info on the plasma cutter in the "manual", but after reading a few posts here (and reducing one tip to slag

) I've happily diced up some 3mm stainless and it seems to work just fine.

) I've happily diced up some 3mm stainless and it seems to work just fine.Then, after reading several other posts on here, I got a bit confused... should the tip be in constant contact with the piece you are cutting ?

Since my torch has one connection to (-)/air, a 2-pin connection for the switch and the return (+) clipped on the piece, I guess it has to be in contact to work.

In practice that seems the case... have I got it right or am I missing something ?

Yours,

Tony Wilk

I believe the torch is an "SG-51" type with bits that look like this:

.

.