You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brain Cloud

- Thread starter Seano

- Start date

Seano

Member

- Messages

- 1,884

- Location

- Devon

Circumference is... Pi x Diameter

So that would be Pi x 250 then wyn...

chunkolini

celebrity artiste

- Messages

- 9,671

- Location

- Swansea

to get the circumference multiply it by three (well 3.142)

I usually go over by about 10-15% and trim the ends off.

I usually go over by about 10-15% and trim the ends off.

Seano

Member

- Messages

- 1,884

- Location

- Devon

to get the circumference multiply it by three (well 3.142)

I usually go over by about 10-15% and trim the ends off.

Multiply what by Pi chunko ? the dia ?

chunkolini

celebrity artiste

- Messages

- 9,671

- Location

- Swansea

Yes diameter x3.

I was very doubtful when a stage building mate of mine told me.

Pi R squared + area

2Pi r = circumference or Pi D

I think,

I had to test it with a piece of string.

Simple. or I am stupid.

I was very doubtful when a stage building mate of mine told me.

Pi R squared + area

2Pi r = circumference or Pi D

I think,

I had to test it with a piece of string.

Simple. or I am stupid.

wyn

Member

- Messages

- 3,759

- Location

- Cardiff

So that would be Pi x 250 then wyn...

No, if you are after a 500mm diameter ring it's Pi x 500 =1571mm long you would need to cut and then roll it into a ring.

Seano

Member

- Messages

- 1,884

- Location

- Devon

Yes diameter x3.

I was very doubtful when a stage building mate of mine told me.

Pi R squared + area

2Pi r = circumference or Pi D

I think,

I had to test it with a piece of string.

Simple. or I am stupid.

Not stupid at all chunko, when you dont use it everyday you do lose it, cheers for info chunko and wyn.....

so by that reckoning to produce an arc it would be Pi x 1/2 dia depending on what size circumference would make the complete circle..... I think that makes sense

so by that reckoning to produce an arc it would be Pi x 1/2 dia depending on what size circumference would make the complete circle..... I think that makes sense

- Messages

- 13,576

- Location

- England

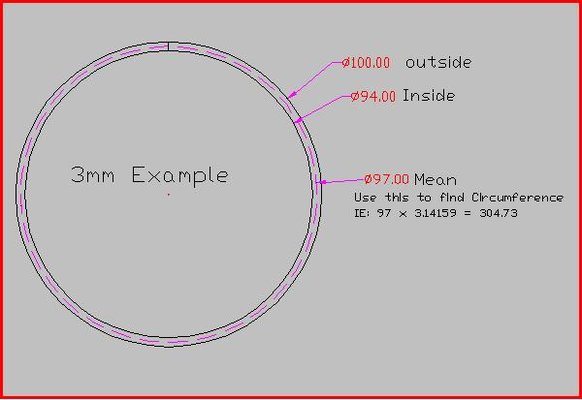

Whats the ring from..... you need to work on the mid line of the material for rolling really....

If i wanted to roll a 1000mm OD ring from 20sq,

you need pi x 980

If you have a pi button, use it, on big numbers it can make a few mm difference.....if not, 3.142 would do.

Then I normally would take a couple of mm off to allow for where the edges might not quite come perfect, and a gap for welding....

Id cut it about 3077

If i wanted to roll a 1000mm OD ring from 20sq,

you need pi x 980

If you have a pi button, use it, on big numbers it can make a few mm difference.....if not, 3.142 would do.

Then I normally would take a couple of mm off to allow for where the edges might not quite come perfect, and a gap for welding....

Id cut it about 3077

Seano

Member

- Messages

- 1,884

- Location

- Devon

No, if you are after a 500mm diameter ring it's Pi x 500 =1571mm long you would need to cut and then roll it into a ring.

This is where I get annoyed with my wife, as in engineering terms when we talk of O/D we mean actually mean the total circumference, but we just naturally call it the O/D, now the figue you have just given me is what I came up with first, but she (being a maths teacher) in a prison mind, swore blind I was wrong, I'm glad you have affirmed my sanity.....

Seano

Member

- Messages

- 1,884

- Location

- Devon

Whats the ring from..... you need to work on the mid line of the material for rolling really....

If i wanted to roll a 1000mm OD ring from 20sq,

you need pi x 980

If you have a pi button, use it, on big numbers it can make a few mm difference.....if not, 3.142 would do.

Then I normally would take a couple of mm off to allow for where the edges might not quite come perfect, and a gap for welding....

Id cut it about 3077

Is that to allow for the shrinkage on the inside Karl ? guess it only comes with experience and use, how much would that change if using flat or round ?

- Messages

- 13,576

- Location

- England

You just need to work on the centre line, (or near as) regardless of flat or round, box, plate....

So you 500mm ring, if its 500 OD and from 50x10 flat....

You'd want 1537 (with a few extra mm removed)

If your 500mm ring is 500 OD and from 50x20, youd want about 1506.

Now if you were rolling wide sections its fractionally different, but with big stuff you need to leave long to allow for rolling anyway.

But the centre line method is close enough for just about everything i have ever done.

So you 500mm ring, if its 500 OD and from 50x10 flat....

You'd want 1537 (with a few extra mm removed)

If your 500mm ring is 500 OD and from 50x20, youd want about 1506.

Now if you were rolling wide sections its fractionally different, but with big stuff you need to leave long to allow for rolling anyway.

But the centre line method is close enough for just about everything i have ever done.

chunkolini

celebrity artiste

- Messages

- 9,671

- Location

- Swansea

Why is your wife in prison?

Seano

Member

- Messages

- 1,884

- Location

- Devon

Why is your wife in prison?

Because she teaches crims Chunko, maths,engrish and It.

This is where I get annoyed with my wife, as in engineering terms when we talk of O/D we mean actually mean the total circumference, but we just naturally call it the O/D, now the figue you have just given me is what I came up with first, but she (being a maths teacher) in a prison mind, swore blind I was wrong, I'm glad you have affirmed my sanity.....

Not sure I understand this.I don't think this terminology would be any different in maths or engineering terms.

O/D is outside diameter which is not the total circumference it is the measurement across the widest bit of the circle.

So 2*Pi*r or Pi*d

Paul.

Moderator

- Messages

- 7,047

- Location

- Northampton. UK

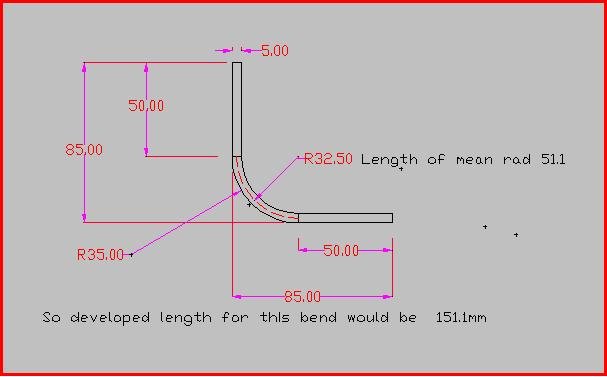

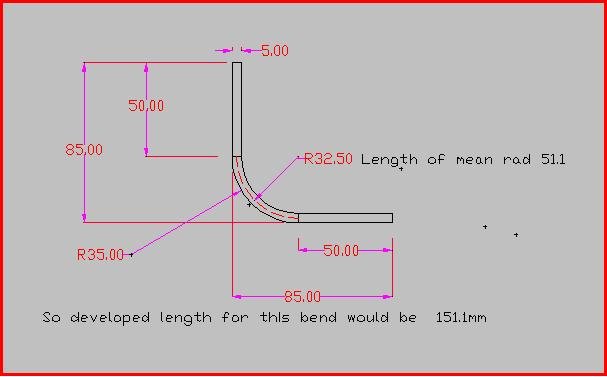

I use this example, which helps my laddies understand.....

Where have I seen that before,

glad its of use.

glad its of use.Rrunnach

Member

- Messages

- 1,133

- Location

- Scotland

Where have I seen that before,glad its of use.

TBH, I can't remember where I sourced drg, was it from yourself, if so, saved me time from drawing out on whiteboard?

Cheers....

Paul.

Moderator

- Messages

- 7,047

- Location

- Northampton. UK

Yes I did it a couple of years ago when the same question was asked

http://www.mig-welding.co.uk/forum/showthread.php?t=16795&highlight=diameter

This any use to you?, shows how to use the mean Dia to develop bend lengths,

http://www.mig-welding.co.uk/forum/showthread.php?t=16795&highlight=diameter

This any use to you?, shows how to use the mean Dia to develop bend lengths,

- Messages

- 14,815

- Location

- UK

Yes I did it a couple of years ago when the same question was asked

http://www.mig-welding.co.uk/forum/showthread.php?t=16795&highlight=diameter

This any use to you?, shows how to use the mean Dia to develop bend lengths,

View attachment 33155

Don't mind if i nick that and stick it on the pressbrake do you?