Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,523

- Location

- France, Brittany.

Evening, my lathe is up and running, and all is good,(thanks to everyones previous help), however, and there's always a however, I have a dual speed electric motor, which was originally attached to some 1940's or 50's electrics which have long since been replaced (within the last 25 years ???) by a modernish electrical cabinet with nice push buttons attached to the lathe.

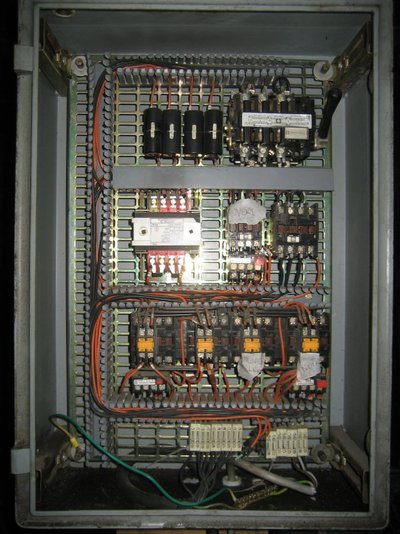

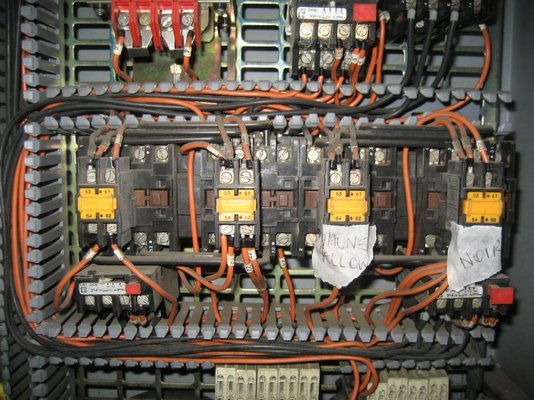

The electrical cabinet is untouched and works fine however when the lathe was moved originally, the cable going to the button box had two or three wires yanked out, these wires controlling the high speed windings on the motor. Photos to come. I have changed alot of the old wires from the control box to the button box and to the motor. No problems here, the problem is I've no idea where these three wires should go. I've had two 'sparkies' pop by become hugely confused and given up.

What works.... I've got the low speed back and fwd, the lube pump on and off, and when I push the 'contactors' for the high speed back and fwd that works, but the latching system is not working as the wires are out and I don't want to risk damaging the system as obviously it's well done and logically it's just the three wires which are needing a home.

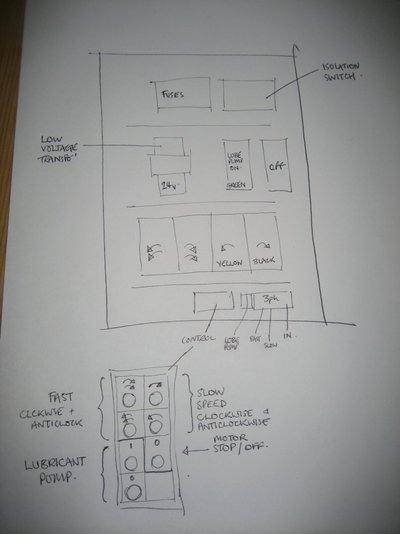

Here's what I understand.... from top to bottom, top right: Isolation Switch, top left: fuses, middle left high to low voltage transformer for the control system kicking out 22 volts in my shed. After that we have the four contactors on the bottom, the two on the right which work and the two on the left which just seem to be missing the impulsion to work. The contactor middle middle right is for the lube pump and I think the contactor middle far right is the stop on the latching system.

What I don't understand...... these contactors are electromagnets which when powered up make a switch close to power the motor.... are these contactors fired on low voltage or 400v? I remember at school very vaguely latching circuits but it's all well vague. Is there as such latching circuits involved or do these clever contactors do it all???? I don't know.

I would be nice to have my little console of buttons working, BUT I have come up with another solution if it's just too complicated to fix, I was thinking I could just bolt a female 3ph socket to my control box and when needing to swap between high and low I could just plug the relevant windings in. This is one solution however it would be nice to have it 'all' working.

I have a pretty good understanding of electrics and chasing things round fuseboxs with my multimeter, but this has got me, and with it plugged in I'm getting so confused by not really being able to understand how it works. So I'm throwing this open if anyone has any constructive ideas fire away, and I've tried following all the wires some of which are numbered but with no success. Anyway here's some photos.

Thanks in advance, yo ho ho.

The electrical cabinet is untouched and works fine however when the lathe was moved originally, the cable going to the button box had two or three wires yanked out, these wires controlling the high speed windings on the motor. Photos to come. I have changed alot of the old wires from the control box to the button box and to the motor. No problems here, the problem is I've no idea where these three wires should go. I've had two 'sparkies' pop by become hugely confused and given up.

What works.... I've got the low speed back and fwd, the lube pump on and off, and when I push the 'contactors' for the high speed back and fwd that works, but the latching system is not working as the wires are out and I don't want to risk damaging the system as obviously it's well done and logically it's just the three wires which are needing a home.

Here's what I understand.... from top to bottom, top right: Isolation Switch, top left: fuses, middle left high to low voltage transformer for the control system kicking out 22 volts in my shed. After that we have the four contactors on the bottom, the two on the right which work and the two on the left which just seem to be missing the impulsion to work. The contactor middle middle right is for the lube pump and I think the contactor middle far right is the stop on the latching system.

What I don't understand...... these contactors are electromagnets which when powered up make a switch close to power the motor.... are these contactors fired on low voltage or 400v? I remember at school very vaguely latching circuits but it's all well vague. Is there as such latching circuits involved or do these clever contactors do it all???? I don't know.

I would be nice to have my little console of buttons working, BUT I have come up with another solution if it's just too complicated to fix, I was thinking I could just bolt a female 3ph socket to my control box and when needing to swap between high and low I could just plug the relevant windings in. This is one solution however it would be nice to have it 'all' working.

I have a pretty good understanding of electrics and chasing things round fuseboxs with my multimeter, but this has got me, and with it plugged in I'm getting so confused by not really being able to understand how it works. So I'm throwing this open if anyone has any constructive ideas fire away, and I've tried following all the wires some of which are numbered but with no success. Anyway here's some photos.

Thanks in advance, yo ho ho.