Bmouthboyo

Keen to Learn

- Messages

- 41

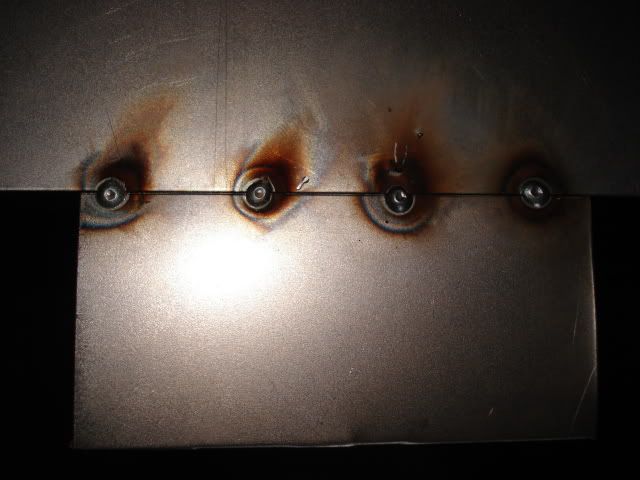

So today I laid my first few beads with my Snap on MIG 130 Turbo on CO2 gas. 0.6mm wire on 1mm steel (bit grubby).

Found it took a while to get the settings to stop blowing through the steel. Even on the lowest (30 amp) it was very hard to lay a continuous bead without blowing through.

I ended up just using the stop start technique which seemed to produce some much more acceptable welds with OK penetration. Do do this I had to up the wire speed to 4/5.

I then tin snipped a bit of the corner out and tack welded it in.

Penetration not so good.

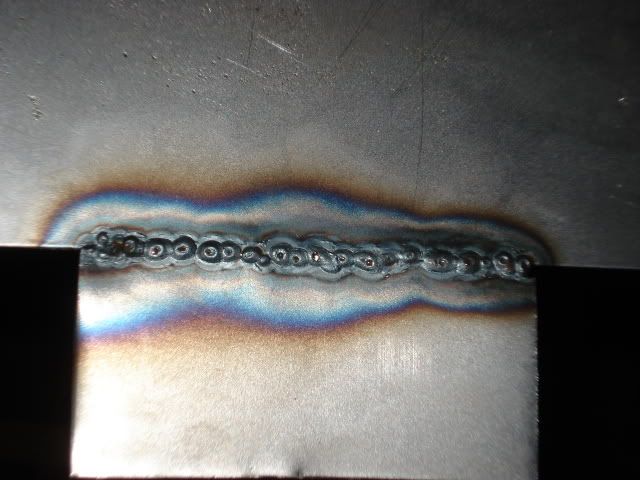

Then stop start welded around.

Again not great penetration

Finally ground back and tell tail signs of lack of penetration.

Can anyone advise how I improve this? Higher wire speed? or leave torch on each tack for longer?

Feel like I learnt a lot from only an hour playing about. Looking forward to practising some more, and reporting back soon.

Found it took a while to get the settings to stop blowing through the steel. Even on the lowest (30 amp) it was very hard to lay a continuous bead without blowing through.

I ended up just using the stop start technique which seemed to produce some much more acceptable welds with OK penetration. Do do this I had to up the wire speed to 4/5.

I then tin snipped a bit of the corner out and tack welded it in.

Penetration not so good.

Then stop start welded around.

Again not great penetration

Finally ground back and tell tail signs of lack of penetration.

Can anyone advise how I improve this? Higher wire speed? or leave torch on each tack for longer?

Feel like I learnt a lot from only an hour playing about. Looking forward to practising some more, and reporting back soon.

I am hopefully picking some steel up next week but I had this laying about in the garage so could resist.

I am hopefully picking some steel up next week but I had this laying about in the garage so could resist.