You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grooving in the lathe.

- Thread starter aametalmaster

- Start date

They can be had for around a fiver.

http://www.ebay.co.uk/itm/V-belt-pu...K_BOI_FarmingEquipment_RL&hash=item19cab636a1

This ones bigger http://www.ebay.co.uk/itm/Multi-V-g...K_BOI_FarmingEquipment_RL&hash=item19cab64f10

4 step larger £21 http://www.ebay.co.uk/itm/Multi-V-g...K_BOI_FarmingEquipment_RL&hash=item19cab64f10

All within 30 secs.

http://www.ebay.co.uk/itm/V-belt-pu...K_BOI_FarmingEquipment_RL&hash=item19cab636a1

This ones bigger http://www.ebay.co.uk/itm/Multi-V-g...K_BOI_FarmingEquipment_RL&hash=item19cab64f10

4 step larger £21 http://www.ebay.co.uk/itm/Multi-V-g...K_BOI_FarmingEquipment_RL&hash=item19cab64f10

All within 30 secs.

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,077

- Location

- North West with water on 3 sides

Well there you go, all finished and ready to go with the right bore and pulley sizes, all in 30 secs. Why bother doing it yourself eh when you can just buy it yourself. This is still a DIY forum hopefully.

yep and 90% of what we all do can be purchased for a fifth of the price but thats no fun...i myself would rather use a tenners worth of leccy and consumables and stand in my workshop all day makin summit that can be bought with a click click ....crazy bunch arnt we

yep and 90% of what we all do can be purchased for a fifth of the price but thats no fun...i myself would rather use a tenners worth of leccy and consumables and stand in my workshop all day makin summit that can be bought with a click click ....crazy bunch arnt we

I was just admiring that! Out of interest, how long did it take to make that piece, looks like quite a lot of material removed.

I'm actually genuinely answered in the answer to the above question. I fall on the side of the fence that I'm more interested in how to make something rather than buying it.

The thing is with the stuff you make, you make it suit exactly the need you have. Most off the shelf stuff isn't quite what you wanted.

aametalmaster

Member

- Messages

- 763

- Location

- Salem Ohio USA

cant beat a good old collet chuck for holding stock stuff

I made that ER 40 collet chuck also as well as the sq tool block. Yes i know you can buy them ready made but its a lot more fun making something than sitting there watching tv all night. Well come to think about it no one had made an ER40 chuck for a lathe ER32 was the largest that you could buy off the shelf ...Bob

aametalmaster

Member

- Messages

- 763

- Location

- Salem Ohio USA

I'm actually genuinely answered in the answer to the above question. I fall on the side of the fence that I'm more interested in how to make something rather than buying it.

The thing is with the stuff you make, you make it suit exactly the need you have. Most off the shelf stuff isn't quite what you wanted.

I prob have a good hour in it from start to finish. That includes the keyway and tapping the set screw hole...Bob

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,077

- Location

- North West with water on 3 sides

I made that ER 40 collet chuck also as well as the sq tool block. Yes i know you can buy them ready made but its a lot more fun making something than sitting there watching tv all night. Well come to think about it no one had made an ER40 chuck for a lathe ER32 was the largest that you could buy off the shelf ...Bob

did you really...looks a great job mate

aametalmaster

Member

- Messages

- 763

- Location

- Salem Ohio USA

did you really...looks a great job mate

Yes and here are some pics. I have a yahoo SB Lathe group with lots of cool metal working pics if anyone is interested in joining. Lots to look at.

http://groups.yahoo.com/group/southbend10k/

http://groups.yahoo.com/group/southbend10k/photos/album/1721405650/pic/list Collet chuck pics.

It took a little time to figure it all out and i didn't have any drawings to look at i just knew what i wanted...Bob

-

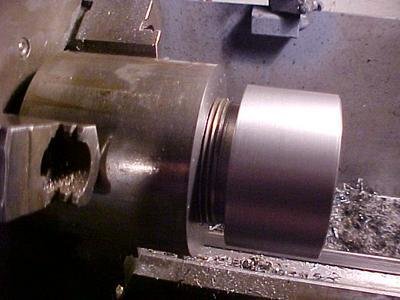

1 chuck body.jpg17.3 KB · Views: 311

1 chuck body.jpg17.3 KB · Views: 311 -

2 chuck body threaded for spindle.jpg27.2 KB · Views: 326

2 chuck body threaded for spindle.jpg27.2 KB · Views: 326 -

3 inside taper cut.jpg15.8 KB · Views: 320

3 inside taper cut.jpg15.8 KB · Views: 320 -

4 trying collet.jpg17.3 KB · Views: 316

4 trying collet.jpg17.3 KB · Views: 316 -

5 threading body for nose cap.jpg18.8 KB · Views: 332

5 threading body for nose cap.jpg18.8 KB · Views: 332 -

6 threaded body and taper.jpg19.5 KB · Views: 317

6 threaded body and taper.jpg19.5 KB · Views: 317 -

7 boring nose hole for threading.jpg13.2 KB · Views: 331

7 boring nose hole for threading.jpg13.2 KB · Views: 331 -

8 nose taper cut and hole bored.jpg14.9 KB · Views: 334

8 nose taper cut and hole bored.jpg14.9 KB · Views: 334 -

9 nose threaded.jpg17.3 KB · Views: 325

9 nose threaded.jpg17.3 KB · Views: 325 -

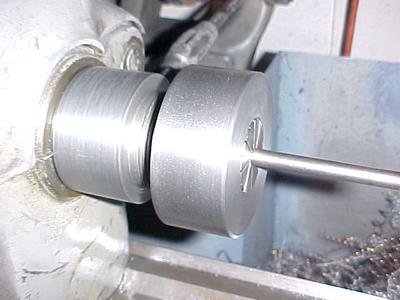

10 collet body screwed inside nose.jpg19.4 KB · Views: 319

10 collet body screwed inside nose.jpg19.4 KB · Views: 319 -

11 done but needs shaping.jpg17.7 KB · Views: 332

11 done but needs shaping.jpg17.7 KB · Views: 332 -

12 after shaping to suit.jpg27.6 KB · Views: 320

12 after shaping to suit.jpg27.6 KB · Views: 320

aametalmaster

Member

- Messages

- 763

- Location

- Salem Ohio USA

What tool was you using in the lathe? I hate parting off/groving on my small lathe.

It was just a 1/4" sq HSS tool bit ground with some side clearence on both sides and some rake on the top. The cross slide gibs were snugged a little too. The cutter was on centerline with the spindle. Hope this helps...Bob