You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SLS pipe leaking - repair options?

- Thread starter JOEPRO

- Start date

JOEPRO

Member

- Messages

- 5,175

- Location

- UK

they were brazed on , so they will un braze the same way , the straight one looks like a re usable hydraulic fitting anyway

Thanks, the banjo fitting is also re usable its plently strong still just pitted in some areas.

I would have to note the clocking of that pointed fitting to be sure the original hose doesnt end up misalingned.

braze is over 800 , silver solder about 650 and solder about 400

I braze things ,,, its stronger and what Im used to doing ,,,

brazing , soldering and silver soldering is all much of a muchness ,,, before you go brazing on the ends , make sure you can get the pipe bent first ,,, leave a few inches on each end you can trim it to length and put the ends on after you get the fit right cleanliness is vital ,,, and dont feed too much braze into thee joint and fill the pipe by mistake ,,, easily done theres something funny about the straight fitting , looks like a reuseable hydraulic fitting , but the braze is odd ,,, but you could get a standard hydraulic fitting swaged onto the rubber if needed ,,,, is it 8mm pipe or 10

I braze things ,,, its stronger and what Im used to doing ,,,

brazing , soldering and silver soldering is all much of a muchness ,,, before you go brazing on the ends , make sure you can get the pipe bent first ,,, leave a few inches on each end you can trim it to length and put the ends on after you get the fit right cleanliness is vital ,,, and dont feed too much braze into thee joint and fill the pipe by mistake ,,, easily done theres something funny about the straight fitting , looks like a reuseable hydraulic fitting , but the braze is odd ,,, but you could get a standard hydraulic fitting swaged onto the rubber if needed ,,,, is it 8mm pipe or 10

JOEPRO

Member

- Messages

- 5,175

- Location

- UK

what condition is the rubber part in , you could get the whole thing made up maybe ,,, just thinking outloud ,,,

The rubber hose all seems in good condition. Id rather just renew the leaking solid pipe

Be very careful with the banjo, i was recently caught out by a pitted one.Thanks, the banjo fitting is also re usable its plently strong still just pitted in some areas.

I would have to note the clocking of that pointed fitting to be sure the original hose doesnt end up misalingned.

seemed ok but ended up with fuel pi$$in everywhere from a pinhole

Given the condition of the rest of it I think it would be foolish not to fit new hoses.

As for the brazing - you need to heat up those fittings to red heat and hold them there whilst you feed the brazing rod and pull the braze down into the joint.

That takes quite a lot of heat. It will greatly help if you can knock up a temporary forge to encapsulate the heat. Firebrick is ideal but paving brick or patio slabs work too if you don't hold the heat directly on them.

As for the brazing - you need to heat up those fittings to red heat and hold them there whilst you feed the brazing rod and pull the braze down into the joint.

That takes quite a lot of heat. It will greatly help if you can knock up a temporary forge to encapsulate the heat. Firebrick is ideal but paving brick or patio slabs work too if you don't hold the heat directly on them.

JOEPRO

Member

- Messages

- 5,175

- Location

- UK

Be very careful with the banjo, i was recently caught out by a pitted one.

seemed ok but ended up with fuel pi$$in everywhere from a pinhole

I see these ones look correct and ill try to order these to NI

Type 9081 Weld on Metric Banjo Soldered or Brazed

Type 9081 Weld on Metric Banjo suitable to use with metric pipe Fitting has to be soldered or brazed These Connectors are USED for Air Water Gas Oil

That way one or both banjo fittings can be renewed.

Given the condition of the rest of it I think it would be foolish not to fit new hoses.

As for the brazing - you need to heat up those fittings to red heat and hold them there whilst you feed the brazing rod and pull the braze down into the joint.

That takes quite a lot of heat. It will greatly help if you can knock up a temporary forge to encapsulate the heat. Firebrick is ideal but paving brick or patio slabs work too if you don't hold the heat directly on them.

Ill take it to RT autoparts and see what they say RE new hose. I dont know if the male fitting in my photos is standard. I guess if they dont have that they could use other fittings to create a new hose section if I bring them the new kunifer pipe sections pre bent and the new banjo fittings brazed on.

I see these ones look correct and ill try to order these to NI

Type 9081 Weld on Metric Banjo Soldered or Brazed

Type 9081 Weld on Metric Banjo suitable to use with metric pipe Fitting has to be soldered or brazed These Connectors are USED for Air Water Gas Oilwww.advancedfluidsolutions.co.uk

That way one or both banjo fittings can be renewed.

Ill take it to RT autoparts and see what they say RE new hose. I dont know if the male fitting in my photos is standard. I guess if they dont have that they could use other fittings to create a new hose section if I bring them the new kunifer pipe sections pre bent and the new banjo fittings brazed on.

Before brazing anything I would bolt on the banjos and dry assemble the whole thing with the kunifer pre bent and your rubber hose tightened up.

With everything clipped in place make clear alignment marks between the pipe and the fittings so that you can braze it in the correct orientation.

JOEPRO

Member

- Messages

- 5,175

- Location

- UK

Before brazing anything I would bolt on the banjos and dry assemble the whole thing with the kunifer pre bent and your rubber hose tightened up.

With everything clipped in place make clear alignment marks between the pipe and the fittings so that you can braze it in the correct orientation.

That will work for one banjo yes but not the other one as the rubber hose will melt. (One banjo is very close to the hose) The second banjo i can align on the car before the hose gets crimped so I will braze both before the new hose

jo1010

Member

- Messages

- 454

- Location

- West Berkshire, uk

@indykid yes, "explosion" is a bit excitable...just trying to get across that a hydraulic burst can be very damaging (to human tissues if nearby) ...and can go with a bang if a component suddenly fails....

Re line pressures ...I was thinking about design pressures and those systems can take 200 bar...

Re line pressures ...I was thinking about design pressures and those systems can take 200 bar...

jo1010

Member

- Messages

- 454

- Location

- West Berkshire, uk

Hydraulics can go with a bang and it all depends on what's near them when they failwhy would it be like an explosion ,,,, thats got me curious ,,,

jo1010

Member

- Messages

- 454

- Location

- West Berkshire, uk

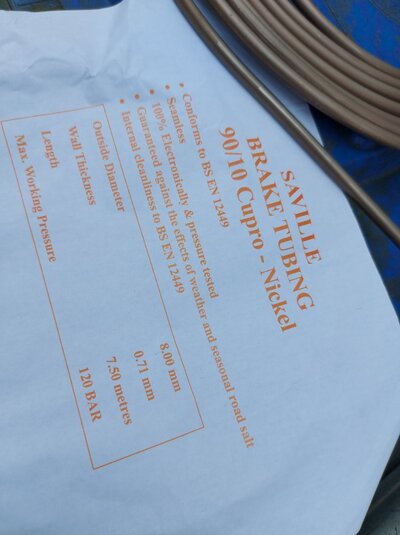

Brazing is the way to go.....just a thought about kunifer if your still thinking of that...the wall thickness is going to limit the max pressure it can handle. There's no doubt it will "work" everything else being equal in normal operation...... just remember that the system is designed at higher max pressure than the kunifer will take......the alternative?....trying to hand bend steel pipe in complicated runs is a pita....

Practically, I'd probably do the same as you though

Practically, I'd probably do the same as you though

Last edited:

Ah , I thought the incompressibility of fluids would have prevented exactly that , as in why fluids used in vessel pressure testing to avoid such things happening , all you get is a squirt .Hydraulics can go with a bang and it all depends on what's near them when they fail

JOEPRO

Member

- Messages

- 5,175

- Location

- UK

Brazing is the way to go.....just a thought about kunifer if your still thinking of that...the wall thickness is going to limit the max pressure it can handle. There's no doubt it will "work" everything else being equal in normal operation...... just remember that the system is designed at higher max pressure than the kunifer will take......the alternative?....trying to hand bend steel pipe in complicated runs is a pita....

Practically, I'd probably do the same as you though

The kunifer tubing I have is rated for 120 bar. I believe it will be fine and im using it.

If it bursts then Ill know it was not fine

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

I assume, an 8 mm OD pipe would be 0,008 m.While I appreciate your concern on gut feel, it feels a touch sensationalist in the context of some maths (also 200 bar is knocking on 3000psi).

Google reckons silver solder will develop somewhere between 70 and 250MPa in shear depending on silver content. Feels about right, so assume worst case, but consider both. Assuming an 8mm OD pipe and some decent high silver solder, that means you need a joint length somewhere between 1.6mm and 5.7mm. That's to react 200bar, which exceeds the 190bar PRV set pressure, not the 50bar normal operating pressure.

I'd be quite confident of making a fully wetted 8-10mm long silver solder joint, but if you're concerned, make some test pieces and section them to make sure you can do it repeatably.

View attachment 522317

Standard disclaimer - this is merely opinion, not advice.

That just pop into my eyes, haven't checked or calced the other columns.

Cunningham's law in action!I assume, an 8 mm OD pipe would be 0,008 m.

That just pop into my eyes, haven't checked or calced the other columns.

Good spot. I was definitely testing you. That'll teach me for doing Engineering at the wrong end of the day and quite a safety factor then....

I'd probably try Kunifer as well, but design pressure for even 1mm thickness 8mm steel pipe is 333bar-The kunifer tubing I have is rated for 120 bar. I believe it will be fine and im using it.

If it bursts then Ill know it was not fine

View attachment 522364

The issue isn't likely to be static pressure, it'll be the shock pressures if you hit something hard.