dpmstevens

New Member

- Messages

- 4

- Location

- London UK

Hi,

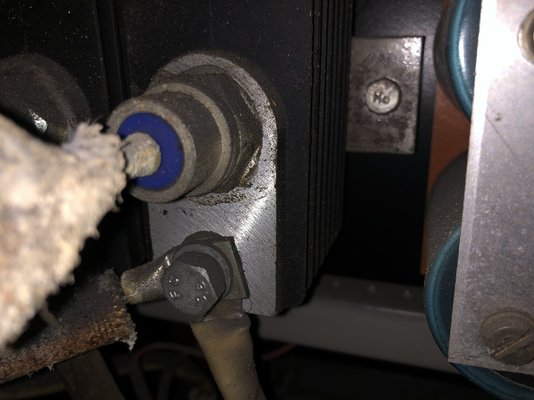

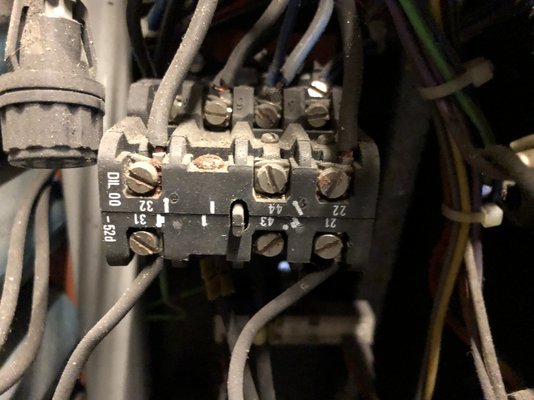

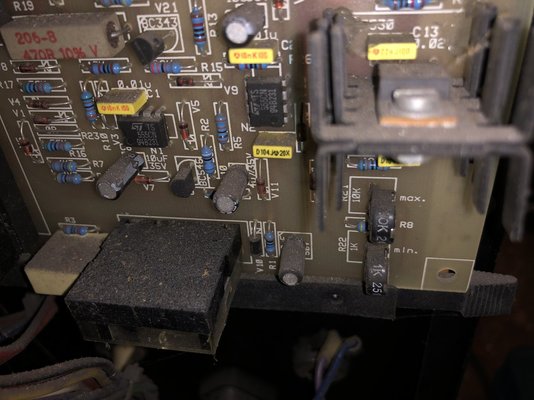

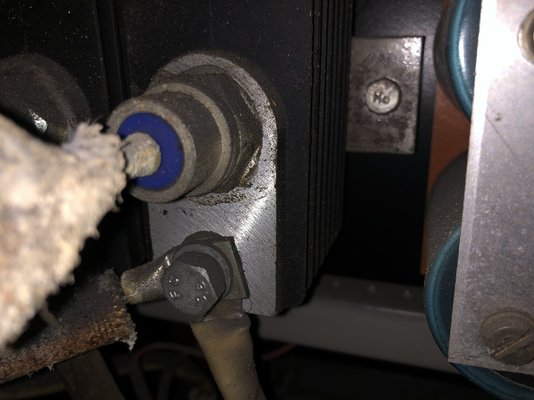

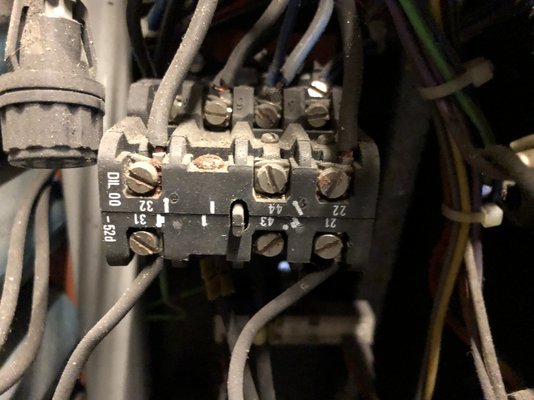

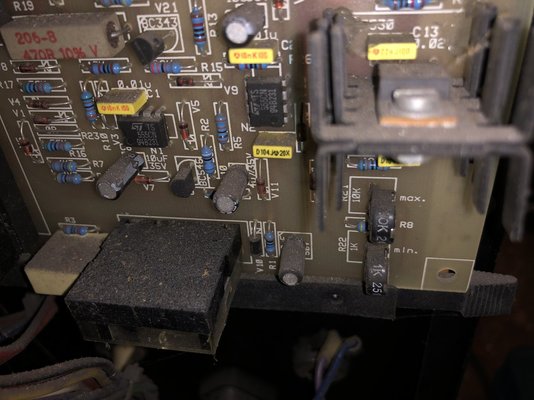

I took the side off my very old Murex 165 Tradesmig last night and realised it's pretty dirty in there. Thing is, I don't know if this is cosmetic or if it could harm the machine.

It works okay, but I'm suffering from intermittent arc strike. Pretty much every other weld results in a failed arc and burn back. It also seems irritatingly sensitive to minor changes in position - it goes from welding fine to utter rubbish. This could be my amateur technique but it happens so often I wonder if there's something up with it. I've changed the liner, the wire, the tip, the shroud and it's still bad.

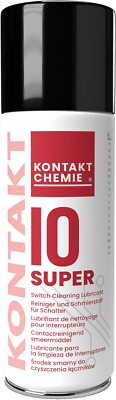

Worth cleaning this lot out?

Cheers

Dan

I took the side off my very old Murex 165 Tradesmig last night and realised it's pretty dirty in there. Thing is, I don't know if this is cosmetic or if it could harm the machine.

It works okay, but I'm suffering from intermittent arc strike. Pretty much every other weld results in a failed arc and burn back. It also seems irritatingly sensitive to minor changes in position - it goes from welding fine to utter rubbish. This could be my amateur technique but it happens so often I wonder if there's something up with it. I've changed the liner, the wire, the tip, the shroud and it's still bad.

Worth cleaning this lot out?

Cheers

Dan