Ross365

Member

- Messages

- 2,104

- Location

- UK

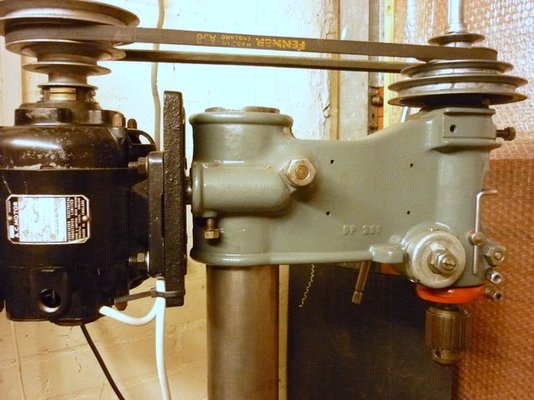

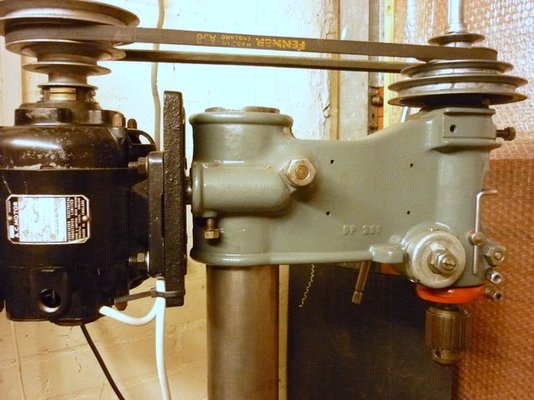

This is my bellowed Tauco pillar drill (made in the USA by Delta in WWII) which I bought on eBay and restored. Recently, I was doing a bit of drilling, and at totally the wrong time, the belt started slipping. I realised that I’d never really figured out the best way to tension the belt, i.e. move the motor away from the drill.

The first pic bellow shows a side view of the drill and the second one shows the possible use of wedges (in orange) to push the motor (supported on each side by a 1” diameter steel guide, marked up in green) away from the drill.

Can anyone tell me if there is a method of tightening the belt that was advised by the manufacture or is otherwise in common use?

Thanks

The first pic bellow shows a side view of the drill and the second one shows the possible use of wedges (in orange) to push the motor (supported on each side by a 1” diameter steel guide, marked up in green) away from the drill.

Can anyone tell me if there is a method of tightening the belt that was advised by the manufacture or is otherwise in common use?

Thanks