You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Dr.Al

Forum Supporter

- Messages

- 2,698

- Location

- Gloucestershire, UK

Nice work. How on earth do you go about measuring / figuring out the bend locations for that?An awkward handrail,steep and variable radius,25solid round.View attachment 465038View attachment 465039View attachment 465040View attachment 465041View attachment 465042View attachment 465043View attachment 465044View attachment 465045View attachment 465046

Arc Tourist

Member

- Messages

- 5,052

- Location

- Wales

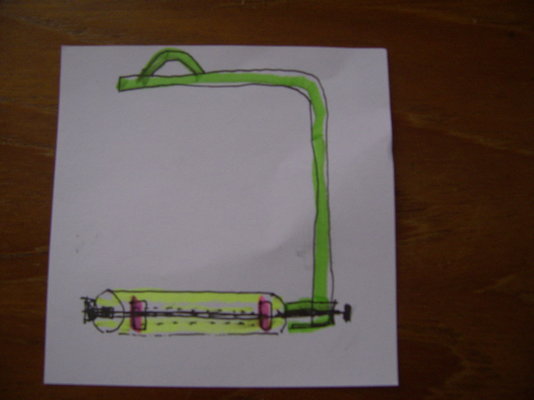

Great Idea. More work, but he only addition I can visualise would a sleeve with bearings over the horizontal stem, which would work for older large lathes with "threaded" mounts. The chuck jaws could be clamped onto the sleeve making the chuck easier to spin off, or on. Here's a rough sketch............................................... but this should work as a prototype.

View attachment 465133

.

That’s not too bad,the hard part is estimating,I quoted £1080+vat,it came out £1284+ vat,so I’ll probably meet them half way.Nice work. How on earth do you go about measuring / figuring out the bend locations for that?

Brad93

Member

- Messages

- 19,425

- Location

- Essex, United Kingdom

Mr. @pressbrake1 has already recommended this to me. When i get the plasma working and make Mk2 I will make the bar rotate.Great Idea. More work, but he only addition I can visualise would a sleeve with bearings over the horizontal stem, which would work for older large lathes with "threaded" mounts. The chuck jaws could be clamped onto the sleeve making the chuck easier to spin off, or on. Here's a rough sketch

.

View attachment 465149

Newlands

Member

- Messages

- 785

- Location

- Sussex, UK

Thicknessing sander. A project I started last year which has stagnated, but I've picked it up again at last, working on the adjustable table. Nominally 150mm wide, it's meant for thicknessing timber down to around 3-6mm to use on my CO2 laser. Quite pleased with how the screw jack turned out, even managed to find a bit of plastic of some sort to make the adjusting knob. Going to make a start on the drum next week, the bit of ally that in there is just a blank waiting to be turned up and mounted on the shaft. Anyone else suffer from projects that go stale and are hard to get going again, or is it just me?

- Messages

- 13,576

- Location

- England

Been a productive day!

Had two pens I had to get done for next weekend as I'm working away Sunday till Saturday.

Pink one is for my eldest ready to start Uni next week.

Green is an order, and the bullet one I just fancied doing, so that one will go in the case for stock.

Pens made whilst paint/glue drying on the Station Master sign.

Had two pens I had to get done for next weekend as I'm working away Sunday till Saturday.

Pink one is for my eldest ready to start Uni next week.

Green is an order, and the bullet one I just fancied doing, so that one will go in the case for stock.

Pens made whilst paint/glue drying on the Station Master sign.

Brad93

Member

- Messages

- 19,425

- Location

- Essex, United Kingdom

Started looking at making this unknown steady fit my TOS. I've got this 2" thick lump of SG iron to make the adapter base from. Centre height is bang on at the minute so i need to relieve the cast iron lump and reduce the base thickness of the steady somewhat to get it to all work out on centre height.

I need to draw it out to make sure the remaining thicknesses will be sufficient from a strength point of view

I need to draw it out to make sure the remaining thicknesses will be sufficient from a strength point of view

Memmeddu

Member

- Messages

- 5,749

- Location

- Italia Sardegna

Mostly painted all the parts for the restoration project minus one which I tried various methods to fill a broken part and I'm most likely going to take it with me at work on Monday an Tig weld it.

I hate to not have the equipment to do things by my own.

I'm not entirely sure if I'm actually going to weld it or just use a die grinder and make it pretty as it doesn't have any critical use.

I hate to not have the equipment to do things by my own.

I'm not entirely sure if I'm actually going to weld it or just use a die grinder and make it pretty as it doesn't have any critical use.

W.olly

Member

- Messages

- 3,895

- Location

- Radcliffe, Manchester

Sort of made it but connected these to together. Bit harder to tune up than the smaller ones i had a while ago. and they were different makes. Saying that these have different motors and motor pulley.

still all good now, Just need a shed over them.

Today i thought be good if i can fit the drain to the front, just need to find the thread sized and fittings and use a copper pipe to taps. should work. Making it easier than pulling them out every other day to drain the tanks.

still all good now, Just need a shed over them.

Today i thought be good if i can fit the drain to the front, just need to find the thread sized and fittings and use a copper pipe to taps. should work. Making it easier than pulling them out every other day to drain the tanks.

sako243

Member

- Messages

- 4,415

- Location

- My mansion in Wales

Following on from this they moved their first bale of straw last week and worked well. What was normally a 45 minutes of faff was down to about 10 minutes if you discount the slow travel to the stable as the horse decided it tasted rather good.One half of the bale spike

View attachment 462514

Just a quick bodge with the holes being plasma cut out of my DIY pallet fork headstock. The weld in bushes go through a 10mm plate on the front, the narrow side of a 80x40x3mm RHS and then another 10mm plate holding on the quick attach hooks, the bush is also welded on one side to the 20mm thick hook that forms part of the quick attach mechanism.

Only going to be used to pick up a handful of 4ft round hay bales and 8x4x4ft straw bales a year so doesn't need to be particularly strong. The headstock is slowly being used, abused and repaired but it's comfortable lifting 2t pallets.

Still not trivial but I am trying to slot a 8x4x4ft bale through a 6x4ft wide gap. Basically push bale in as far as possible then wedge in place with 6x2s and then swing JCB around to "precisely" push it into place.

Edit: oh and to get it in the bale has to be at 45° to the vertical

addjunkie

Member

- Messages

- 14,309

- Location

- Northumberland. Reet oot in the sticks

Change to wood pellet bedding!Following on from this they moved their first bale of straw last week and worked well. What was normally a 45 minutes of faff was down to about 10 minutes if you discount the slow travel to the stable as the horse decided it tasted rather good.

Still not trivial but I am trying to slot a 8x4x4ft bale through a 6x4ft wide gap. Basically push bale in as far as possible then wedge in place with 6x2s and then swing JCB around to "precisely" push it into place.

Edit: oh and to get it in the bale has to be at 45° to the vertical

View attachment 465191

Threads on the drain plug normally 1/4" or 3/8" bsp. They are loctited in so a bit of heat is needed to unscrew them.Sort of made it but connected these to together. Bit harder to tune up than the smaller ones i had a while ago. and they were different makes. Saying that these have different motors and motor pulley.

still all good now, Just need a shed over them.

Today i thought be good if i can fit the drain to the front, just need to find the thread sized and fittings and use a copper pipe to taps. should work. Making it easier than pulling them out every other day to drain the tanks.

View attachment 465169

View attachment 465170

I used push in air fittings and nylon air pipe for the extension out through a wall finishing with a 1/4" ball valve.

addjunkie

Member

- Messages

- 14,309

- Location

- Northumberland. Reet oot in the sticks

I reckon there about the same price as straw for us, but far less volume to repurpose after use. We cant-use shavings or sawdust as it ruins alpaca fleece, pellets don't. But on cost comparison pellets cheaper by the pallet, than shavings and as you buy them as fuel no 20% vatFar more expensive, well at least shavings even with free sawdust from the local woodyard.

sako243

Member

- Messages

- 4,415

- Location

- My mansion in Wales

Actually thinking about it we did use some as an absorbant mat underneath the shavings. We don't have an issue with "repurposing" as one of our nearby neighbours runs a flower business so they take everything Kitty produces as manure. Just before we offered it to them they'd just had to pay a huge amount for 6t of compost. The day after I show up wit 6t of free manure for them  .

.

The bale of straw was £80 (not many local places down here make straw so it's all imported from England) but I think we were paying more than that in pellets and shavings by comparison. We didn't have to buy by the pallet as our local farmers co-op would give us the pallet rate for what we needed.

.

.The bale of straw was £80 (not many local places down here make straw so it's all imported from England) but I think we were paying more than that in pellets and shavings by comparison. We didn't have to buy by the pallet as our local farmers co-op would give us the pallet rate for what we needed.

Dr.Al

Forum Supporter

- Messages

- 2,698

- Location

- Gloucestershire, UK

A very simple mitred-and-splined oak box, again made using my travel tool chest while on holiday in Brittany. The splines (made of red oak) are quite hard to see, but they'll probably be more obvious once I've oiled the box (which will probably happen when I get back home).

As well as the splines, I also used red oak for the lining (again I expect the colour contrast to be more obvious once oiled):

As well as the splines, I also used red oak for the lining (again I expect the colour contrast to be more obvious once oiled):

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

That puppy must have felt very relieved after dropping that out his back end .

That puppy must have felt very relieved after dropping that out his back end .DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

Only pull the first wellie half way off so you are still able to stand inside the calf covering bit , put that foot on the muddy jack and fully remove the other boot . having obviously got a pair of easy to put on croc's handy close by on clean ground .Far superior to the one I made. Same problem though. Dirty wellies, pull off one using the other foot to hold it down. Now you have dirt on the platform. How do you pull off the other boot without getting your sock dirty?

Or am I wrong as usual?