Pete.

Member

- Messages

- 15,054

- Location

- Kent, UK

As posted previously I bought this small grinder which was in many pieces and had to go scouring around to find all the bits amongst the huge amount of stuff.

It came with this small pile of accessories.

After doing some research I figured it to be a Union Grinder, but every pic I could find of those showed a machine with a rounded-front casting and small switch. Mine has a square front and larger switch.

Here's the Lathes page for the machine: http://www.lathes.co.uk/uniontool&cuttergrinder/

They mention a later variant by Harrison and I've found one pic of one of those that appears to have the same square casting: http://vintagemachinery.org/photoindex/detail.aspx?id=33988 so it appears that mine must be the Harrison variant even though it has not markings or machine plate.

Anyway, I have stripped it down and apart from being very dirty and full of dried up grease and covered in a thin film of rust it's in very good condition. First to go was the top table. I stripped off the centres and removed the two clamp bolts and off it came

The main table was in good nick underneath and came off by removing the right stop and wnding the table off the end.

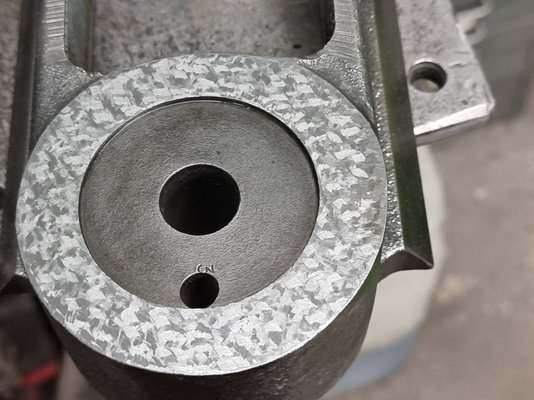

The ways underneath showing signs of scraping which means the machie has had little use.

I then removed the cross table and screw, which just hangs on a pivot bolt on the main casting. I got thoat off, plus the motor from the column which is just held on 2 bolts, then the column wound out of the top leaving just the rise and fall gear which came out by knocking out two taper pins and a couple of grub screws.

Here is the base with the square casting and large swtich shown. If it ever had a nameplate on the front, there's no evidence of it now.

So the plan it do do minor sanding and filling, a bit of scraping, find a way to drive the 250W motor and put it all back together. The motor, thankfully, is 3 phase dual voltage.

Since the pic I have re-connected the windings for 'MESH' connection, which is another term used for 'DELTA', so it can run from 240v supply.

I'm not sure if I'll use a capacitor for a steinmetx connection or fit a small VFD. I have a VFD which is suitable for this small motor but need to find somewhere to hang it. With it only being 250w it might be too under-powered to run from a generated field connection. We will have to see.

It came with this small pile of accessories.

After doing some research I figured it to be a Union Grinder, but every pic I could find of those showed a machine with a rounded-front casting and small switch. Mine has a square front and larger switch.

Here's the Lathes page for the machine: http://www.lathes.co.uk/uniontool&cuttergrinder/

They mention a later variant by Harrison and I've found one pic of one of those that appears to have the same square casting: http://vintagemachinery.org/photoindex/detail.aspx?id=33988 so it appears that mine must be the Harrison variant even though it has not markings or machine plate.

Anyway, I have stripped it down and apart from being very dirty and full of dried up grease and covered in a thin film of rust it's in very good condition. First to go was the top table. I stripped off the centres and removed the two clamp bolts and off it came

The main table was in good nick underneath and came off by removing the right stop and wnding the table off the end.

The ways underneath showing signs of scraping which means the machie has had little use.

I then removed the cross table and screw, which just hangs on a pivot bolt on the main casting. I got thoat off, plus the motor from the column which is just held on 2 bolts, then the column wound out of the top leaving just the rise and fall gear which came out by knocking out two taper pins and a couple of grub screws.

Here is the base with the square casting and large swtich shown. If it ever had a nameplate on the front, there's no evidence of it now.

So the plan it do do minor sanding and filling, a bit of scraping, find a way to drive the 250W motor and put it all back together. The motor, thankfully, is 3 phase dual voltage.

Since the pic I have re-connected the windings for 'MESH' connection, which is another term used for 'DELTA', so it can run from 240v supply.

I'm not sure if I'll use a capacitor for a steinmetx connection or fit a small VFD. I have a VFD which is suitable for this small motor but need to find somewhere to hang it. With it only being 250w it might be too under-powered to run from a generated field connection. We will have to see.