JOEPRO

Member

- Messages

- 5,190

- Location

- UK

So when the part is removed from evaporust, what further work needs to be done.

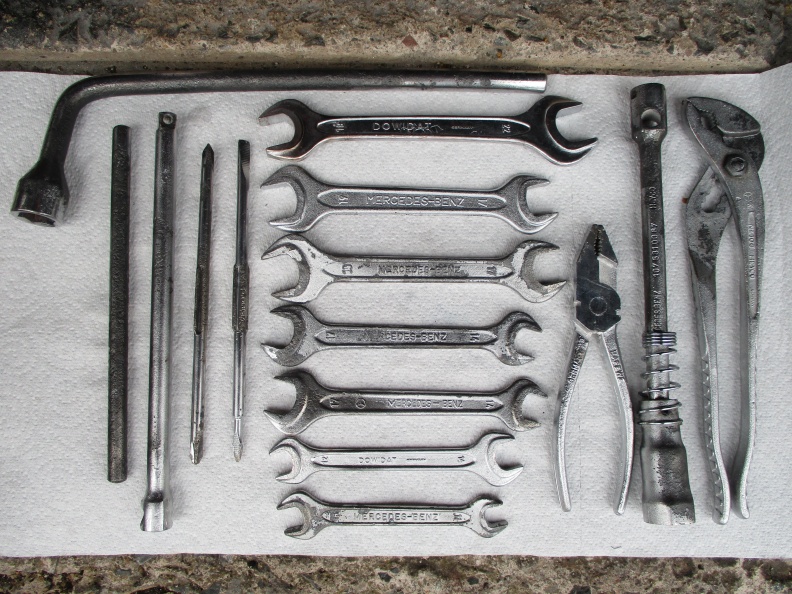

My go-to is electrolysis but after removal from the tank I still wire brush or pressure wash (or both) the part. I also spray with WD40 to stop flash rusting or brush with phosphoric acid, so still a process after removal from the tank.

A good part of the electrolysis treatment is it does not affect clean steel and as such have used it on stub axles without worry of the clean bearing surfaces being effected - how does evaporust work on parts like that?

Another good thing with electrolysis is I have used a 200ltr drum to clean a land rover axle case (one end at a time) so that would require a significant volume of liquid.

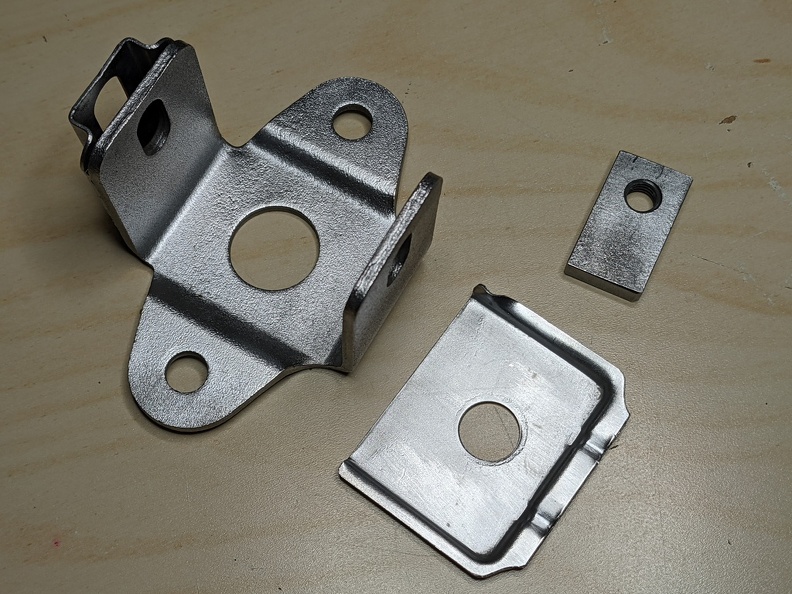

It will be interesting to hear the full cleaning process of the evaporust, but that part certainly does look nice and clean.

There is very little on the evaporust front.

The part should not have oil or grease on it. Otherwise just drop it in and leave it in the solution.

Remove and I washed the part in utility sink and dried thoroughly with compressed air. That was it. No wire brushing etc required at all the rust is completely gone and the fluid is odourless kind of like diesel consistency.