Tmate

Member

- Messages

- 62

- Location

- U.S. Maryland

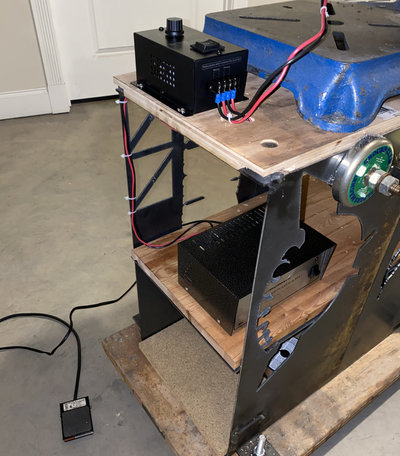

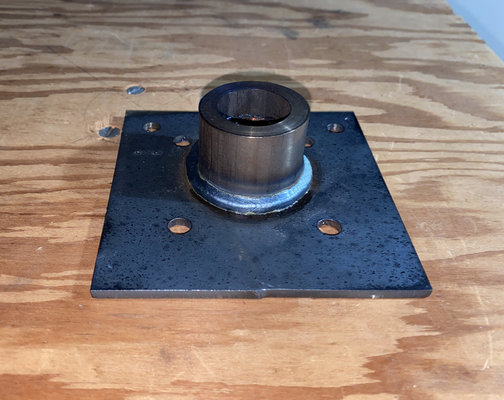

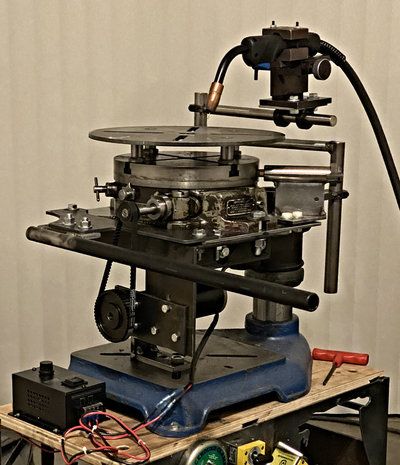

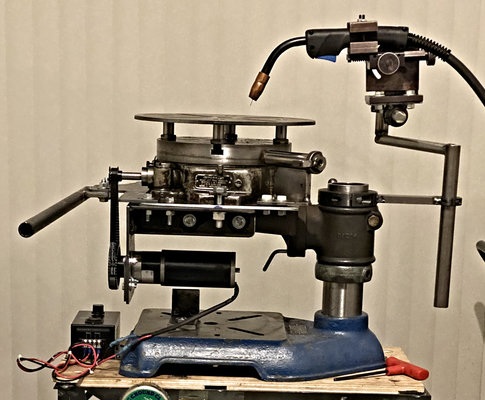

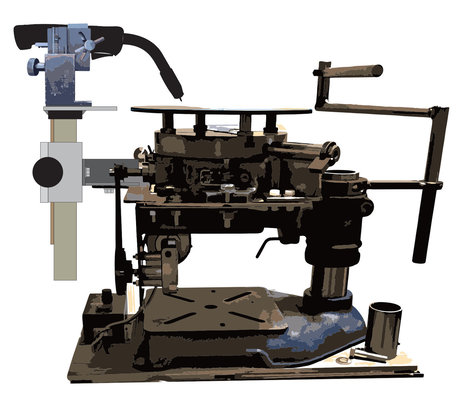

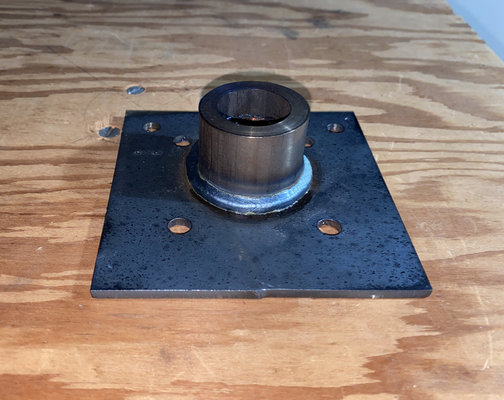

I combined an old Troyke rotary milling table with some drill press parts to make a variable speed welding positioner.

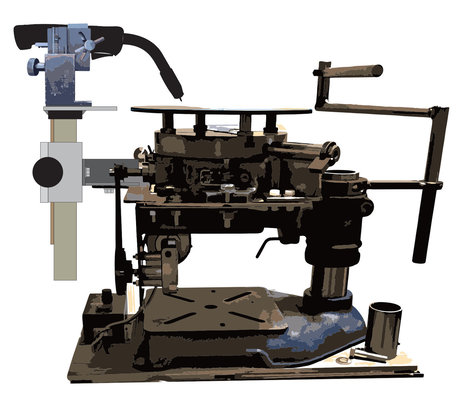

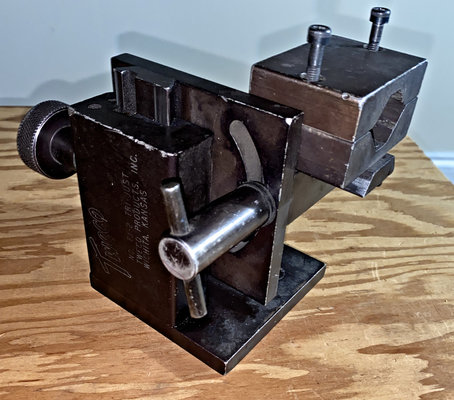

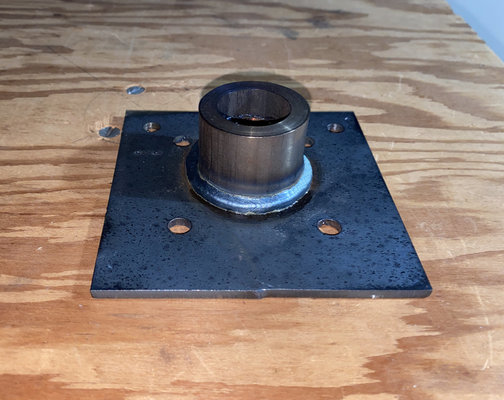

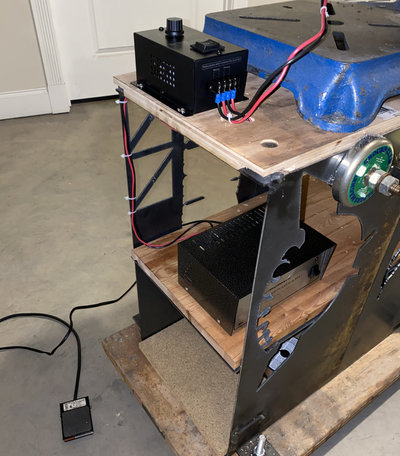

Spring loaded brass rod riding against the table provides the ground. It is insulated via nylon bolts and flat washers. Ground cable gets clamped to upright part of bracket. Three clamping shaft collars and some scrap steel bars make a super-sturdy adjustable hand rest. It uses an 8 amp. 12 volt DC power supply and a separate speed control. Future plans call for an adjustable torch mounting bracket and solenoid trigger control (see sketch).

Spring loaded brass rod riding against the table provides the ground. It is insulated via nylon bolts and flat washers. Ground cable gets clamped to upright part of bracket. Three clamping shaft collars and some scrap steel bars make a super-sturdy adjustable hand rest. It uses an 8 amp. 12 volt DC power supply and a separate speed control. Future plans call for an adjustable torch mounting bracket and solenoid trigger control (see sketch).