julianthegypsy

Member

- Messages

- 4,394

- Location

- Cirencester

You wouldn't necessarily need to centrifuge it, just heat it to about 95⁰ in a pan and skim it off. You'd get better results if you had a pressure cooker too. Bung all your seeds in with a little bit of water and steam it for ten minutes, then run it through your screw press. That's a crude version of the way palm oil is extracted. If you have a vacuum pump you could vacuum off the last bit of water. If you have a glass flask you can watch it boiling off too, it's quite fun!I made a strange looking test part, very coarse tapered thread in a straight shaft, quite cool.

View attachment 358044

It's an expeller press, for crushing the oil out of nuts and seeds, the final part would be stainless, twice and long and narrower flights/wider flutes, probably more trapezoidal than square threadform too. In use it would slowly rotate in a housing, which I think needs lengthways grooves, seeds would be fed in at the "deep" end, be forced along to the shallow end, crushing them leaving the oil and any water in them to flow back along the grooves and out of a screen, and dry smushed up seed pulp to come out the end.

I probably won't actually build it though, I don't know how I'd machine the grooved housing, I don't know what I'd power it with or how I'd attach it, I doubt a Kitchenaid has the torque and I'd be worried about breaking the juice extractor if it seizes. Plus, I imagine for the oil to be any use in cooking it would need to go through a centrifuge after pressing to separate the oil from any water and any solids that make it through. You can actually buy an oil press to fit a juicer, not cheap though. It's good to know I can machine the auger anyway, I'll keep thinking about designing the rest of it until I get distracted by a new idea, I'll have moved on by tomorrow knowing me.

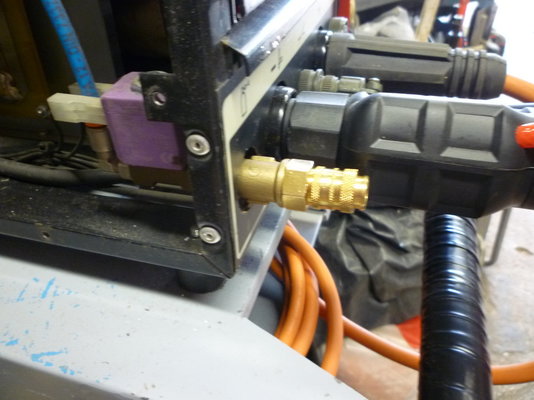

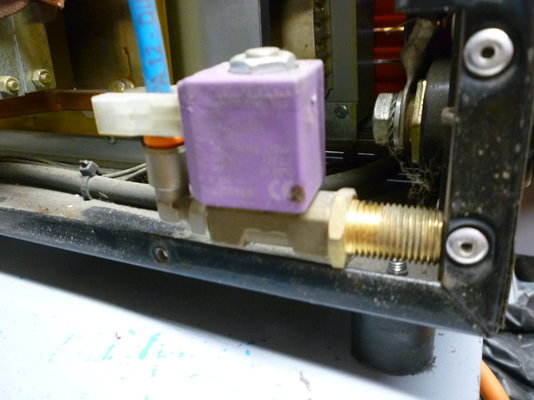

that was friday night so a bit of head scratching . now luckily for me front and rear gas fittings on this machine are 1/4" male bsp so of to the plumbers merchant this morning for these

that was friday night so a bit of head scratching . now luckily for me front and rear gas fittings on this machine are 1/4" male bsp so of to the plumbers merchant this morning for these