Well i started a new project for my spare time, but since im new to welding i am unsure about what material to use for the project , therefore unsure about which weld equipment to buy. The point is to build a frame more like the Ariel Atom frame. i've looked into ERW steel tube (sizes: 2.5" .065 wall, 2" .083wall, and back's support, is 2.5" .120) wall or Duralumin (an aluminum alloy which is very strong".

Therefore, the question is for those experienced which would be a better material for a frame, taking into consideration weight and security ( aprox acceleration of this project when finished 0-60 3.5-4 sec, top speed 150+ mph). and second which is a better weld process for the material chosen (TIG or MIG or ARC)

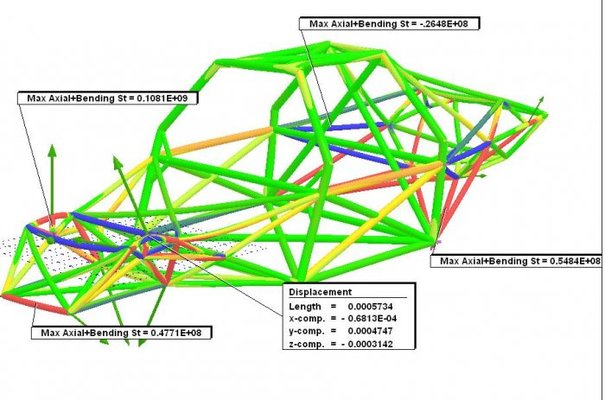

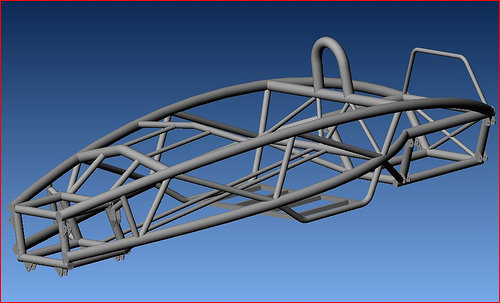

Thanks to everyone who can help. i got this frame off of the internet so is somewhat like this what i plan to build

Therefore, the question is for those experienced which would be a better material for a frame, taking into consideration weight and security ( aprox acceleration of this project when finished 0-60 3.5-4 sec, top speed 150+ mph). and second which is a better weld process for the material chosen (TIG or MIG or ARC)

Thanks to everyone who can help. i got this frame off of the internet so is somewhat like this what i plan to build

This is a subject of much debate and the outcome of most of them is "steel will last but aluminium will stress and crack especially under heavy use" Also the aluminium section needed to supply the necessary strength will weigh as much as steel by the time it's all reinforced and braced adequately.

This is a subject of much debate and the outcome of most of them is "steel will last but aluminium will stress and crack especially under heavy use" Also the aluminium section needed to supply the necessary strength will weigh as much as steel by the time it's all reinforced and braced adequately. Having more expertise available is the best resource and as the original poster says he's prepared to practice. A lot of the welds are going to be very similar (tube/tube of the same material) so it's probably feasible. You have the SVA test in the UK anyway don't you? Reassuring to see you can't just build a car from pipe, sling a V8 in it and career all over town.

Having more expertise available is the best resource and as the original poster says he's prepared to practice. A lot of the welds are going to be very similar (tube/tube of the same material) so it's probably feasible. You have the SVA test in the UK anyway don't you? Reassuring to see you can't just build a car from pipe, sling a V8 in it and career all over town.

) - I'm now very happy to do car sill replacement, wing repairs, MOT work, gates, etc.

) - I'm now very happy to do car sill replacement, wing repairs, MOT work, gates, etc.