Endacy

Member

- Messages

- 278

Radial drill - three phase to single phase conversion - lots of pictures

The problem - my new radial drill was three phase

The issues: 415v contactors, knackered electrics, motor is coupled to a gearbox - no belt.

My solution...

Here is the drill, the motor was removed at this point and is sitting on the bed, it goes right at the top vertically mounted.

Here is the English Electric three phase motor. Lovely condition and well made. 240/415v three phase only. 3/4" shaft size, 36mm length from mounting face. 3/4hp.

The motor bolted to this 15mm plate, which in turn bolted to the top of the gearbox:

I am replacing the motor with a single phase one, didn't like the idea of an inverter, especially as a local company said they could kill older motors. But they did try to sell me a £250 replacement motor instead.

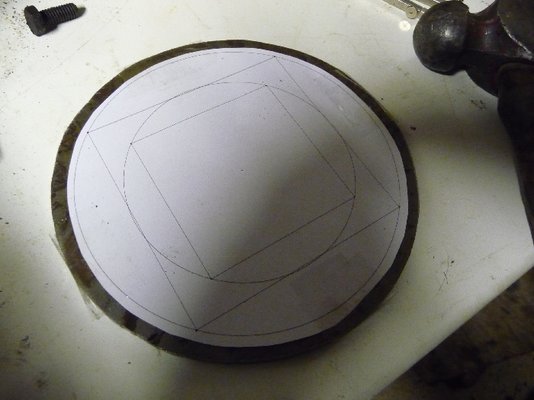

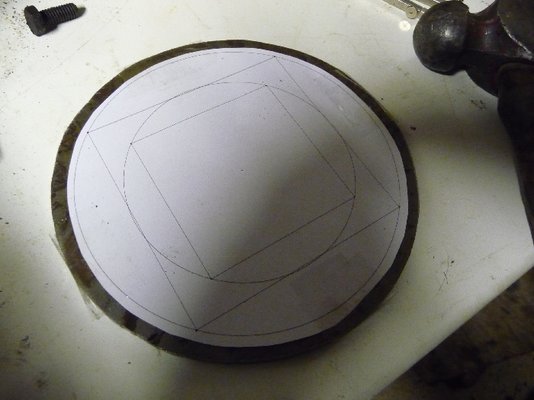

Anyway here is the template I made for a 80 frame B14 face mount, I drew this in adobe illustrator. The corners of the squares are the centres of the holes to be drilled. Outer holes match the old motor mounting holes in the 15mm plate, inner holes on a 100mm PCD. The plate underneath is a 5mm steel circle I cut out with a jigsaw. Long job that. The centre of the plate is punched and lined up with a centre mark on my template to centre it all up.

LOTS of jigsawing and drilling and filing and filing and filing, and I created a conversion plate from the template. New motor arrived from a seller on ebay, just under £80 with postage, B14 face mount instead of foot mount.

New motor, to be bolted to plate on left, to be bolted to plate on right, to be bolted to gearbox:

Some wiring going on, old stuff was ruined, £10 on some plastic conduit and 4 fittings from B&Q:

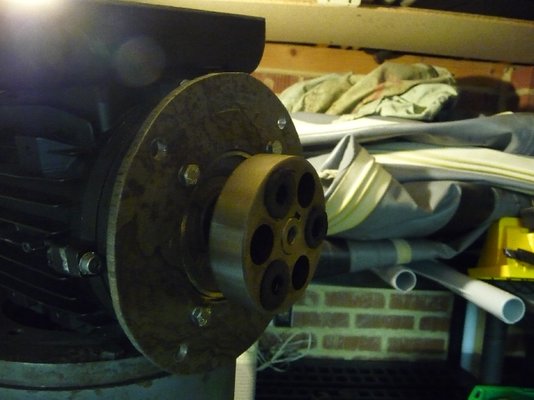

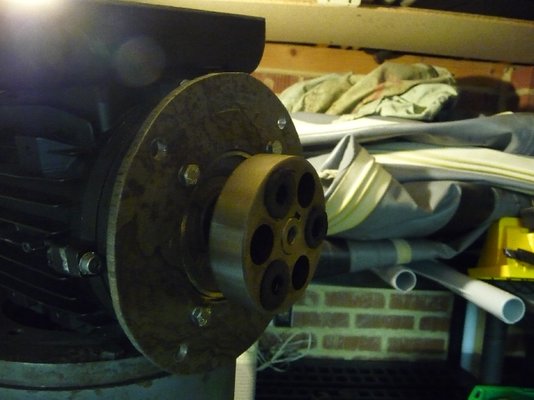

This is the part that attaches to the motor, it has a 3/4" internal diamater, which is close enough to 19mm so as not to matter. Imperial keyways are smaller though so I had a local company re-cut the keyway to a metric 6mm, and fit two grub screws because it was an interference fit on the imperial shaft, but loose on the metric one:

View inside top of the gearbox, with other half of pin and bush coupling. 15mm plate also bolted back on ready:

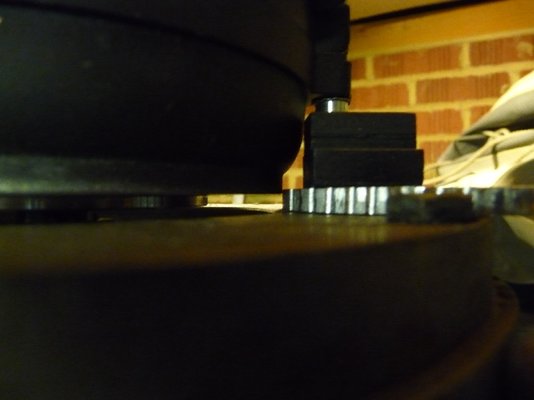

Coupling on the new motor:

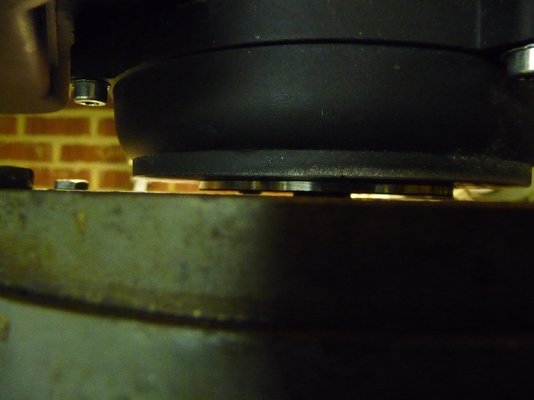

Plonked onto the gearbox coupling and my planning has worked, the 80 frame motor has a shaft length of 40mm from the mounting face, old one was 36mm (ish) giving me the clearance for my new conversion plate:

Offcut of the steel plate on the right showing the difference in height with the motor sitting on it's coupling:

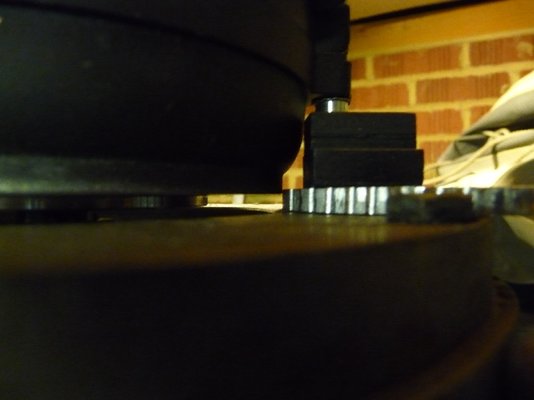

No worries as the motor will be around 1mm high, i'll use one of these 1mm washers I made myself (!) from 1mm aluminium sheet, placed under the coupling on the gearbox to raise it up:

Showing where the new conversion plate will go:

In the end there was no need for the washers, I left the gearbox side as it was and moved the coupling slightly on the motor shaft:

Motor and home made plate:

Motor on gearbox:

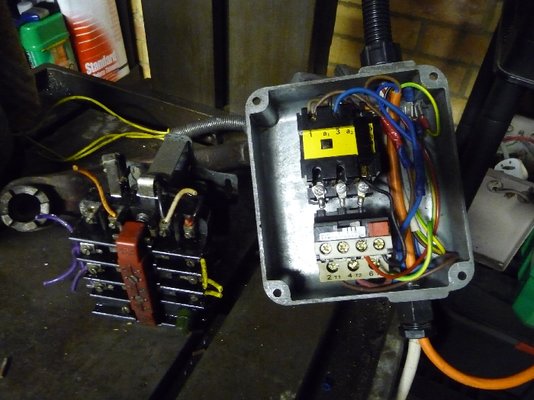

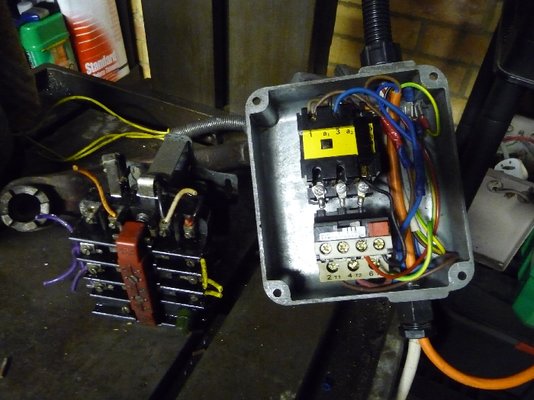

Old contactor on left, new and in places modified modern contactor and overload:

Vice on the old bench drill:

Vice on the new drill:

Done! All electrics renewed but used the original start / stop switches. New tee nuts on the table to bolt work down. Just need to put new gearbox oil in and it's finished.

The problem - my new radial drill was three phase

The issues: 415v contactors, knackered electrics, motor is coupled to a gearbox - no belt.

My solution...

Here is the drill, the motor was removed at this point and is sitting on the bed, it goes right at the top vertically mounted.

Here is the English Electric three phase motor. Lovely condition and well made. 240/415v three phase only. 3/4" shaft size, 36mm length from mounting face. 3/4hp.

The motor bolted to this 15mm plate, which in turn bolted to the top of the gearbox:

I am replacing the motor with a single phase one, didn't like the idea of an inverter, especially as a local company said they could kill older motors. But they did try to sell me a £250 replacement motor instead.

Anyway here is the template I made for a 80 frame B14 face mount, I drew this in adobe illustrator. The corners of the squares are the centres of the holes to be drilled. Outer holes match the old motor mounting holes in the 15mm plate, inner holes on a 100mm PCD. The plate underneath is a 5mm steel circle I cut out with a jigsaw. Long job that. The centre of the plate is punched and lined up with a centre mark on my template to centre it all up.

LOTS of jigsawing and drilling and filing and filing and filing, and I created a conversion plate from the template. New motor arrived from a seller on ebay, just under £80 with postage, B14 face mount instead of foot mount.

New motor, to be bolted to plate on left, to be bolted to plate on right, to be bolted to gearbox:

Some wiring going on, old stuff was ruined, £10 on some plastic conduit and 4 fittings from B&Q:

This is the part that attaches to the motor, it has a 3/4" internal diamater, which is close enough to 19mm so as not to matter. Imperial keyways are smaller though so I had a local company re-cut the keyway to a metric 6mm, and fit two grub screws because it was an interference fit on the imperial shaft, but loose on the metric one:

View inside top of the gearbox, with other half of pin and bush coupling. 15mm plate also bolted back on ready:

Coupling on the new motor:

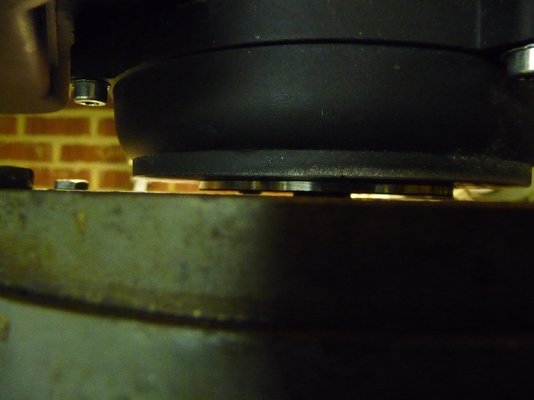

Plonked onto the gearbox coupling and my planning has worked, the 80 frame motor has a shaft length of 40mm from the mounting face, old one was 36mm (ish) giving me the clearance for my new conversion plate:

Offcut of the steel plate on the right showing the difference in height with the motor sitting on it's coupling:

No worries as the motor will be around 1mm high, i'll use one of these 1mm washers I made myself (!) from 1mm aluminium sheet, placed under the coupling on the gearbox to raise it up:

Showing where the new conversion plate will go:

In the end there was no need for the washers, I left the gearbox side as it was and moved the coupling slightly on the motor shaft:

Motor and home made plate:

Motor on gearbox:

Old contactor on left, new and in places modified modern contactor and overload:

Vice on the old bench drill:

Vice on the new drill:

Done! All electrics renewed but used the original start / stop switches. New tee nuts on the table to bolt work down. Just need to put new gearbox oil in and it's finished.

Last edited: