I recently purchased a vertical harrison miling machine, the machine was wired for 400 volts, I connected it up to my 400 volt chinese 2.2kw vfd and the machine would only run in the lower gears and lacked any power in the high gears, I just figured my vfd was crap so I decided to try a hunyang 220 volt vfd of higher kw rating, 4 kw to be precise.

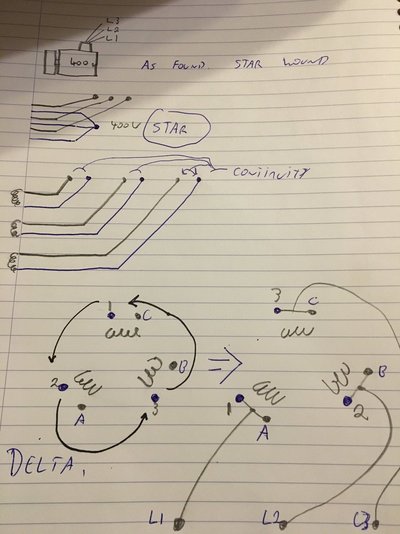

after a struggle I removed the main motor of the machine, the machine was clearly wired for star 400v connection but I also noted the motor was a 6 pole 990rpm motor of heavy construction, there were 6 wires, non of which were labeled as far as I could see, 3 black wires and 3 red wires. the 3 black wires were bolted together for the star connection and the 3 reds left the motor for l1,l2 and l3.

in my lack of wisdom I thought , just change the connection for delta , so with a multimeter set for continuity I isolated 3 pairs of wires with continuity, the coils I thought.

here is where I believe I may have messed up, the u v w wires,

I had no way, well my brain couldnt figure out which was which so in my mind I made a triangle out of the pairs of connected coils and then rotates the connections of the black uvw wires 1 place or 120 degrees and connected these new pairs to my l1,l2,l3.

I connected up my vfd to the 3 selected wires and my motor ran smoothly and at 50 hz it attained the rated rpm as I checked this with a tacho, now not the smartest but this was on a vfd I didnt care for I switched two of the black uvw wires deliberately to make a fault and sure enough the motor wouldn't run or if it did it was rough, so happy with my efforts I reinstalled my motor to my mill and connected it up to my 220 v 4kw huanyang vfd, same if not slightly worse , no power in higher two gears and after much messing about with vfd settings and torque boost settings its still the same and here I am begging your wisdom and guidance, pictures to follow soon thanks for your help!

after a struggle I removed the main motor of the machine, the machine was clearly wired for star 400v connection but I also noted the motor was a 6 pole 990rpm motor of heavy construction, there were 6 wires, non of which were labeled as far as I could see, 3 black wires and 3 red wires. the 3 black wires were bolted together for the star connection and the 3 reds left the motor for l1,l2 and l3.

in my lack of wisdom I thought , just change the connection for delta , so with a multimeter set for continuity I isolated 3 pairs of wires with continuity, the coils I thought.

here is where I believe I may have messed up, the u v w wires,

I had no way, well my brain couldnt figure out which was which so in my mind I made a triangle out of the pairs of connected coils and then rotates the connections of the black uvw wires 1 place or 120 degrees and connected these new pairs to my l1,l2,l3.

I connected up my vfd to the 3 selected wires and my motor ran smoothly and at 50 hz it attained the rated rpm as I checked this with a tacho, now not the smartest but this was on a vfd I didnt care for I switched two of the black uvw wires deliberately to make a fault and sure enough the motor wouldn't run or if it did it was rough, so happy with my efforts I reinstalled my motor to my mill and connected it up to my 220 v 4kw huanyang vfd, same if not slightly worse , no power in higher two gears and after much messing about with vfd settings and torque boost settings its still the same and here I am begging your wisdom and guidance, pictures to follow soon thanks for your help!

but the power from these vfds is no comparison whatsoever but honestly my 2.2kw vfd runs the mill equally if not better than my 4 kw vfd so im at a loss, I was never trying to start the mill at 100 hz either sorry for the miss communication, I just went out and ran the mill there in lower gear and yes warmed up fully it can run the mill in its top gear but I used to be able to spin a 2'' shell mill at 2800 rpm and just smash through aluminium etc but even at 2000 rpm this mill wouldnt cut butter with a 2'' shell mill

but the power from these vfds is no comparison whatsoever but honestly my 2.2kw vfd runs the mill equally if not better than my 4 kw vfd so im at a loss, I was never trying to start the mill at 100 hz either sorry for the miss communication, I just went out and ran the mill there in lower gear and yes warmed up fully it can run the mill in its top gear but I used to be able to spin a 2'' shell mill at 2800 rpm and just smash through aluminium etc but even at 2000 rpm this mill wouldnt cut butter with a 2'' shell mill