Dutch Welder

Member

- Messages

- 411

- Location

- Oss, The Netherlands

With you being a miracle worker the railing work should be a simple finger snap and a silent muttering of abracadabra and it should fix itself mate.

Hmmm.... I'm not sure about that mateWith you being a miracle worker the railing work should be a simple finger snap and a silent muttering of abracadabra and it should fix itself mate.

thin stainless isn't my strong point - and I don't have the boat it is supposed to be going on. The marine engineer I'm doing this for will test fit tomorrow and mark any adjustments. I've tacked it up for now...

thin stainless isn't my strong point - and I don't have the boat it is supposed to be going on. The marine engineer I'm doing this for will test fit tomorrow and mark any adjustments. I've tacked it up for now...Absolute poppy cock!thin stainless isn't my strong point -

please be carefull what you type into google images ,magicwave and not as i thought magicwand.

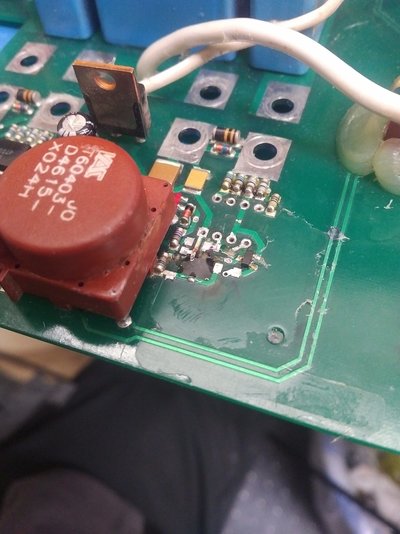

Depends what they are Jim, and the nature of the failure but I'm always game for looking at stuff...Would you like some more PCBs to play with Hugh?

It's only a massagerwell it is in the fronius section not the hitachi. (don't google that).

That sounds like an easy fix - I'm particularly good at surface mount inspection - send it over and I'll take a lookI’ve got a maddening fault on an EWM wire feeder board. If you flex it it works, if it is left in it’s normal at rest position it doesn’t. I’ve replaced it with a new one but it would be nice to have it fixed up as a spare as the feeder board in the old Phoenix machines seem to be the pcb I’ve replaced most over the years. Hardly surprising though, feeders get a hard life on the fleet.

You lucky person - I've had a couple of times to rework 0201s, 0402 is the norm for us unless it's power supply related.0603 is the norm for me at work building prototype boards, we use a little 0402 but try to avoid it as we are not space constrained although we run 6 layer on our main card.

I think 0402 is the industry standard these days - we're certainly behind the curve when it comes to layout (our software, our processes, our sizes) but it does us no harm sticking with the larger size stuffYou lucky person - I've had a couple of times to rework 0201s, 0402 is the norm for us unless it's power supply related.

Layout guys loved me though - gave them a big PCB area to work with (A4ish) and then asked them to cram pretty much all 2000+ components into one corner as it was the only one we had clearance height wise