I am sure that some of you here use lifting gear professionally, so hope you do not mind me picking your brains.

Back in March time'ish the climbers (who have all been trained by recognised bodies), bought in some metal straps for lifting operations, Typically sub 50kg, things like antennas, microwave dishes etc to the tops of towers.

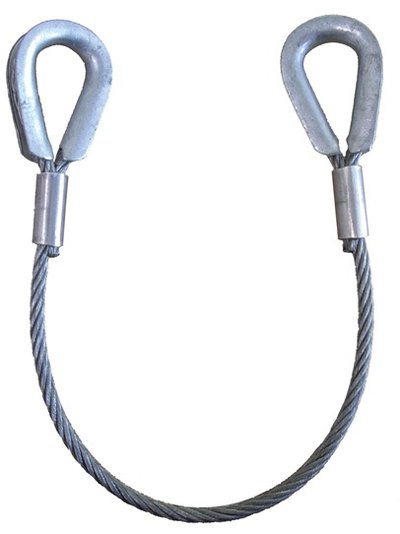

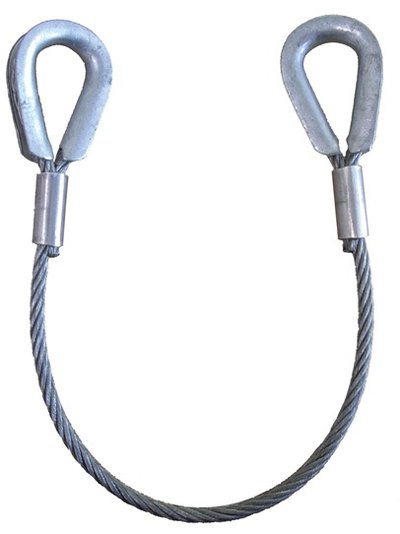

We hire in things like capstan winches when needed but keep our own ropes, a few pulleys and these slings in particular the slings are steel wire with eyelets and crimp bands

Similar style to the image above.

Now for some reason I have always thought that these would need load testing, but I think that is down to my ignorance. I have some documentation making it's way to me, but believe it should be inspections checking for kinks, necking, broken strands, rust, etc on them and that it is not required to load test. Is this correct?

They are typically stored in the building, dry and out of harms way, would have certification when bought etc.

I am about to raise a non conformity, probably on myself as I have missed these items, the lads do visual inspections, but I need to formalise our record keeping and a formal procedure for the checks/inspections, on these, any ropes, pulleys etc.

At the moment there is just an entry into a ticket system to say they need inspecting and an climber says they have inspected

As said the lads have been trained and passed tests on use etc, they tell me that inspections are all that is needed, but I am keen that we do not fall behind on the record keeping, so before my documentation arrives at work some time I thought it worth a question as to what is industry norm.

Adrian

Back in March time'ish the climbers (who have all been trained by recognised bodies), bought in some metal straps for lifting operations, Typically sub 50kg, things like antennas, microwave dishes etc to the tops of towers.

We hire in things like capstan winches when needed but keep our own ropes, a few pulleys and these slings in particular the slings are steel wire with eyelets and crimp bands

Similar style to the image above.

Now for some reason I have always thought that these would need load testing, but I think that is down to my ignorance. I have some documentation making it's way to me, but believe it should be inspections checking for kinks, necking, broken strands, rust, etc on them and that it is not required to load test. Is this correct?

They are typically stored in the building, dry and out of harms way, would have certification when bought etc.

I am about to raise a non conformity, probably on myself as I have missed these items, the lads do visual inspections, but I need to formalise our record keeping and a formal procedure for the checks/inspections, on these, any ropes, pulleys etc.

At the moment there is just an entry into a ticket system to say they need inspecting and an climber says they have inspected

As said the lads have been trained and passed tests on use etc, they tell me that inspections are all that is needed, but I am keen that we do not fall behind on the record keeping, so before my documentation arrives at work some time I thought it worth a question as to what is industry norm.

Adrian