normspanners

Member

- Messages

- 8,842

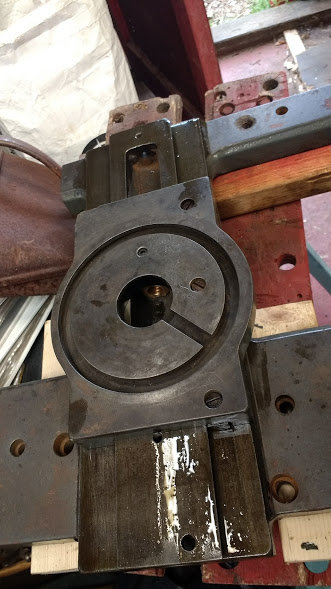

I had a DSG with cross slide issues BUT one thing is--- that is a left hand thread and a guy I did a 'swapsy job' for him on his car he was a turner and he said no problem I can make all that for you, Itll take me a few weeks though so rather than take it and copy he made it from measurements,----- great meant I could still use the lathe whilst it was being done he rang for a few more measurements as the weeks passed and he came down and fitted it. All was fine and it fitted perfectlyLooks like a new nut is in order have a lump of bronze but unsure of the flavour I am thinking this should really be aluminium bronze in this application.

But what is the TPI I was expecting 250 graduations but the dial is marked as 240?

but when we turned the cross thread to screw it in----- it went out !!

but when we turned the cross thread to screw it in----- it went out !! well I thought as he had made it and spent ages on it and seeing that it worked fine with no play, I thought ok a little change of automatic hand movement required,

well I thought as he had made it and spent ages on it and seeing that it worked fine with no play, I thought ok a little change of automatic hand movement required, a little sticky arrow helped and I got used to it------ BUT------ it was hell when I went to use a 'normal' lathe

a little sticky arrow helped and I got used to it------ BUT------ it was hell when I went to use a 'normal' lathe  my brain went into meltdown !!!

my brain went into meltdown !!! and when I upgraded it was hell coz I couldnt then tell, what was 'normal'.

and when I upgraded it was hell coz I couldnt then tell, what was 'normal'.

it cost quite a few TC tips and jobs.