Nerkus

New Member

- Messages

- 5

- Location

- Spain

Hi mates,

I'm work in a worshop and our speciality is pharmaceutical equipments and today we a "little problem " .... <-- joke.

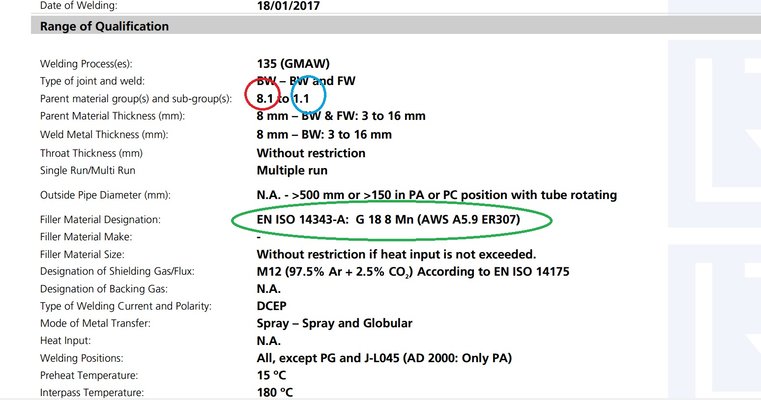

One welder was welding with Cronigon 15 - stainless steel 304L with steel S275JR ... MIG system and filler weld 307.

The weld doesn't have porosity....amazing and not fisures...how much critical is this weld? Could it broke? The equipment works -1/+3 bar and this weld is the stiffeners with jacket.

Thank you so much and sorry by my English.

I'm work in a worshop and our speciality is pharmaceutical equipments and today we a "little problem " .... <-- joke.

One welder was welding with Cronigon 15 - stainless steel 304L with steel S275JR ... MIG system and filler weld 307.

The weld doesn't have porosity....amazing and not fisures...how much critical is this weld? Could it broke? The equipment works -1/+3 bar and this weld is the stiffeners with jacket.

Thank you so much and sorry by my English.

I dont like this comment... could be a problem

I dont like this comment... could be a problem