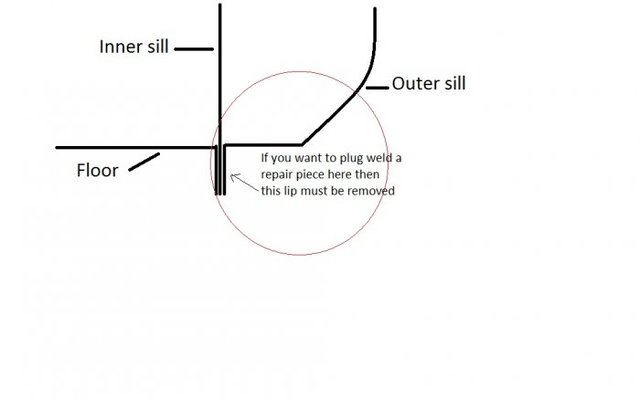

Most car sills comprise a box section formed by two C sections arranged to face one another with a projecting lip top & bottom which is spot welded.

Q - I have often wondered if replacing a small section or the entire bottom can you just seam weld a plate across, with plug welded double L-angle to replicate the lip?

A simple plate would not be as stiff, unless of substantially increased thickness .

Thanks.

Q - I have often wondered if replacing a small section or the entire bottom can you just seam weld a plate across, with plug welded double L-angle to replicate the lip?

A simple plate would not be as stiff, unless of substantially increased thickness .

Thanks.

......i've been thinking anything other than a full sill is classed as a patch ....so whilst using plugs to position ,i've also seam welded the bottom edge...I've had no problems with mot tests either...

......i've been thinking anything other than a full sill is classed as a patch ....so whilst using plugs to position ,i've also seam welded the bottom edge...I've had no problems with mot tests either...