knoba

...break a leg!

- Messages

- 863

- Location

- Sussex, England

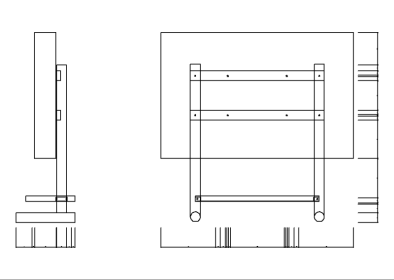

What's the best way to go about captivating m6 nuts in16swg 50mm round hollow section 304 stainless steel? The tubes are 1m long and the threads are, supposed to be, in the middle.

I'm using a MIG and stain-shield with a purge line, I've tried drilling 4mm holes either side of the main7mm bolt hole to aid penetration, but the welds look like they've only just caught the nuts...

Is there some mystery technique for doing this kinda thing?

I'm using a MIG and stain-shield with a purge line, I've tried drilling 4mm holes either side of the main7mm bolt hole to aid penetration, but the welds look like they've only just caught the nuts...

Is there some mystery technique for doing this kinda thing?

(Triumphs, Type 1's and the master cylinder job on a Morris minor come to mind for some reason! - God... I'm getting old!) But, I know what you mean and thank you! it's a good idea that expands the available arrangements greatly. :thumbs:

(Triumphs, Type 1's and the master cylinder job on a Morris minor come to mind for some reason! - God... I'm getting old!) But, I know what you mean and thank you! it's a good idea that expands the available arrangements greatly. :thumbs: