MoreWellie

Forum Supporter

- Messages

- 1,893

- Location

- Warwickshire, UK

I need to attach a replacement 6mm bracket to a land rover axle housing (I believe pressed steel) and have been experimenting with an old axle housing to see whether it is possible with my 150amp mig.

I took an 50mm x 70mm piece of the 6mm plate, stood it on the cleaned axle and ran a fillet along one side only my son then clouted it on the opposite side with a 2lb hammer. It came off with 3 hits (I expected a bit more but he is strong!)

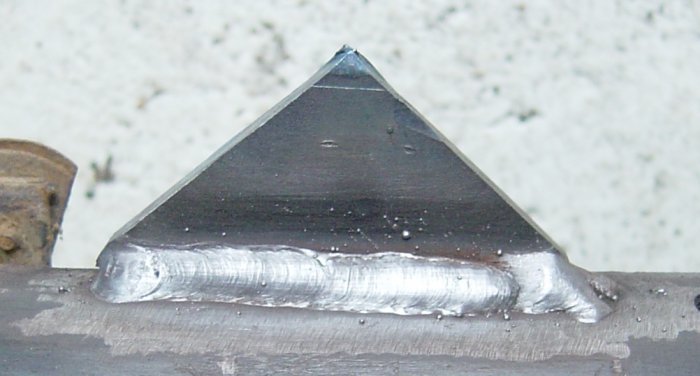

The weld stayed on the axle and the surface broke off the 6mm plate. You can see the weld started at the right hand side and obviously had more penetration at the left

My question is was it good enough or do I need more amps, if yes what would be enough?

We took a chisel to the remaining weld and tried to knock it off the axle but weren't able to. Funny as I expected it to stick better to the plate and break off the axle. It does worry me a bit that I cannot see much (if any) discolouration around the weld on the axle

I took an 50mm x 70mm piece of the 6mm plate, stood it on the cleaned axle and ran a fillet along one side only my son then clouted it on the opposite side with a 2lb hammer. It came off with 3 hits (I expected a bit more but he is strong!)

The weld stayed on the axle and the surface broke off the 6mm plate. You can see the weld started at the right hand side and obviously had more penetration at the left

My question is was it good enough or do I need more amps, if yes what would be enough?

We took a chisel to the remaining weld and tried to knock it off the axle but weren't able to. Funny as I expected it to stick better to the plate and break off the axle. It does worry me a bit that I cannot see much (if any) discolouration around the weld on the axle