WikingWelder

New Member

- Messages

- 3

I 'm teaching myself to tigweld, finding a lot of help in the Internet.

Unfortunately I didn't learn, what I was taught

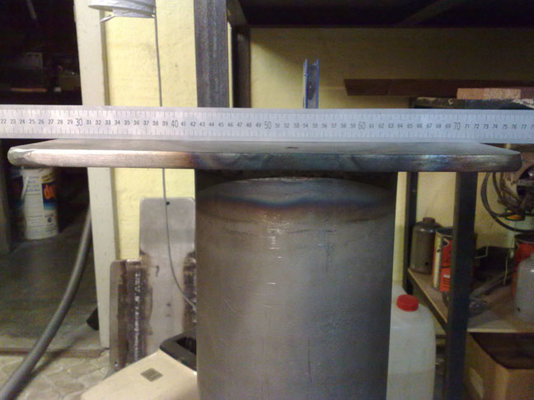

I'm making a stand for my tabledrill, welding a 10"x13"x 5/8" plate of mild steel to a 9" pipe with a 1/4" wall thickness

I got too excited and kept on welding, instead of backtracing and changing spots, and the plate got too hot and warped :-(

Kicking myself doesn't seem to help, so I've decided to try and reheat it on the other side. I intend to use a gas torch with a narrow flame on the opposite side of the weld. I was hoping someone could give me a pointer as to how hot I should make it. I do have an infrared thermo reader, or I can use a redhot scale.

Unfortunately I didn't learn, what I was taught

I'm making a stand for my tabledrill, welding a 10"x13"x 5/8" plate of mild steel to a 9" pipe with a 1/4" wall thickness

I got too excited and kept on welding, instead of backtracing and changing spots, and the plate got too hot and warped :-(

Kicking myself doesn't seem to help, so I've decided to try and reheat it on the other side. I intend to use a gas torch with a narrow flame on the opposite side of the weld. I was hoping someone could give me a pointer as to how hot I should make it. I do have an infrared thermo reader, or I can use a redhot scale.

Last edited: