- Messages

- 14,817

- Location

- UK

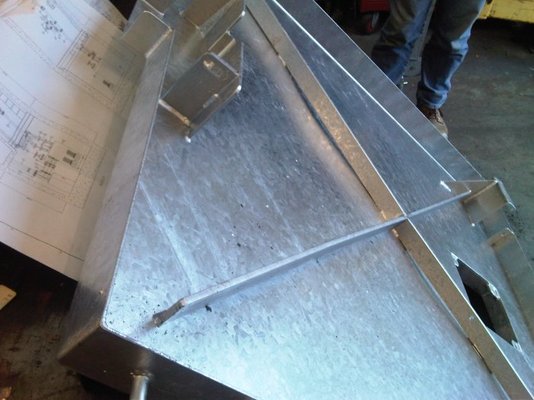

Big lid come back from the galvanisers this morning, 1700mm ish square with a 90mm turndown. Fabbed from 4mm plate. Has stiffeners welded on the inside corner to corner. Lid is diamond pressed corner to corner. Obviously the heat from the galvanising process has mad a mess of it. The 4mm has pulled away from the stiffeners where its not welded, creating a load of 'bubbles' on the sections between the corner to corner creases. Cutting the welds between the plate and the stiffeners does not release anything.

Need to get this sorted asap, as we have a load more riding on this 'sample'.

Time is also of the essence.

Reckon if the stiffeners are cut off, and the creases are re-pressed that it will straighten it up. The stiffeners would then have to be rewelded back in to stop the thing wobbling around.