Hello all

I'm Mike from Cedar Hill TX and I want to learn to weld. I am a master tinkerer, handyman extrordinaire, and all-around good guy. I restore old cars, antique jukeboxes, etc and have yet to master the fine art of welding. I can always "get by" but my work is never pretty, and most assuredly will require lots of grinding after the fact.

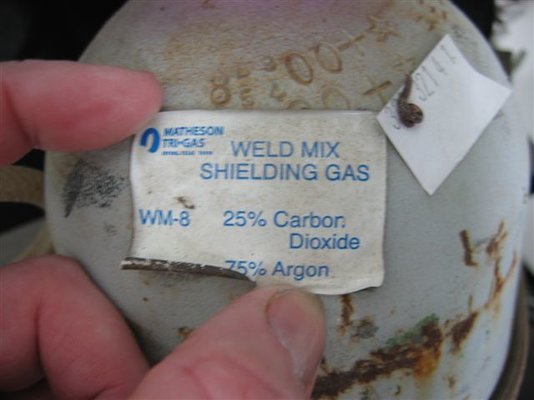

In my arsenal of weaponry I have a 110v SIP HandyMIG 80 and a 220v Century 160. The HandyMIG is gasless. I have quite a bit of metal work ahead of me on my current project. It would really help to improve my welding skills as I will be replacing some floor pans and a trunk floor in an old 1970 Mustang.

The trunk floor is first, I have removed the old floor and have the new part fitted and prepped. Most all of it will plug weld in place. the repop panel is made of a cheap metal and is about .035 thick and is very soft. I have made sure all attaching surfaces are ground clean and shiny. The attaching structiure will be the same thickness or thicker than the floor.

I really want this to look nice. I plan to use the Century welder on this with gas. Thoughts on machine settings, wire type, weld thru primer? I have some .024 wire that looks like copper loaded in it right now. Appreciate any advice you guys might offer.

Great site!

I'm Mike from Cedar Hill TX and I want to learn to weld. I am a master tinkerer, handyman extrordinaire, and all-around good guy. I restore old cars, antique jukeboxes, etc and have yet to master the fine art of welding. I can always "get by" but my work is never pretty, and most assuredly will require lots of grinding after the fact.

In my arsenal of weaponry I have a 110v SIP HandyMIG 80 and a 220v Century 160. The HandyMIG is gasless. I have quite a bit of metal work ahead of me on my current project. It would really help to improve my welding skills as I will be replacing some floor pans and a trunk floor in an old 1970 Mustang.

The trunk floor is first, I have removed the old floor and have the new part fitted and prepped. Most all of it will plug weld in place. the repop panel is made of a cheap metal and is about .035 thick and is very soft. I have made sure all attaching surfaces are ground clean and shiny. The attaching structiure will be the same thickness or thicker than the floor.

I really want this to look nice. I plan to use the Century welder on this with gas. Thoughts on machine settings, wire type, weld thru primer? I have some .024 wire that looks like copper loaded in it right now. Appreciate any advice you guys might offer.

Great site!