Geodawg

Member

- Messages

- 66

- Location

- Glasgow

Hi guys,

been sitting on the side lines and read a lot of stuff that is pointing me in the right direction. But there's one question I hope you can put me right on. I have a SEALEY MIGHTYMIG 150 Professional Gas/No-Gas machine which I got a while back for a very good price, with the intention of learning enough to allow me to patch my van (ongoing project).

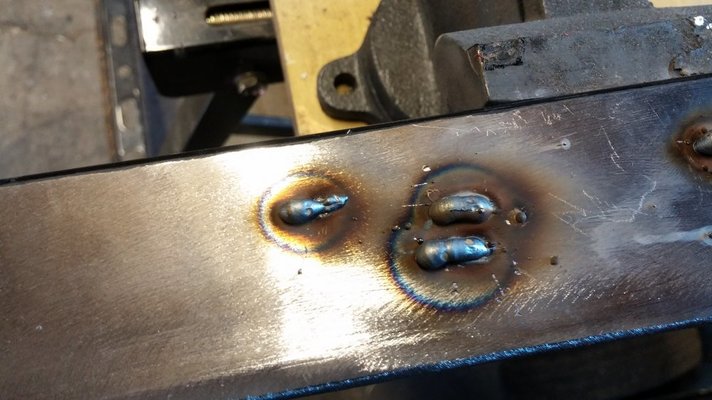

The machine came with a 0.6 tip and a 0.9 tip and 0.9 flux core wire. I've been playing with the 0.9 and not too impressed with my results so far (not put off) but was wondering if I can use 0.8 flux core with the 0.9 tip? I'm also thinking of converting to gas and going down the 'BOC Volkszone deal' route. In your opinion would I be better getting the same size tips as wire. and since the majority of the stuff I plan to do will be patches for the van (thin metal), should I go for a 0.6 or 0.8 tip and wire?

thanks for any advice you can offer.

Geo

been sitting on the side lines and read a lot of stuff that is pointing me in the right direction. But there's one question I hope you can put me right on. I have a SEALEY MIGHTYMIG 150 Professional Gas/No-Gas machine which I got a while back for a very good price, with the intention of learning enough to allow me to patch my van (ongoing project).

The machine came with a 0.6 tip and a 0.9 tip and 0.9 flux core wire. I've been playing with the 0.9 and not too impressed with my results so far (not put off) but was wondering if I can use 0.8 flux core with the 0.9 tip? I'm also thinking of converting to gas and going down the 'BOC Volkszone deal' route. In your opinion would I be better getting the same size tips as wire. and since the majority of the stuff I plan to do will be patches for the van (thin metal), should I go for a 0.6 or 0.8 tip and wire?

thanks for any advice you can offer.

Geo

I'll drop Sealey an email see if the do a spare. If they don't, do you have any advice on a replacement torch?

I'll drop Sealey an email see if the do a spare. If they don't, do you have any advice on a replacement torch?