bluebobtail

Member

- Messages

- 293

Well i finished my nvq level 2 last week, so thought i'd practise some tig work as i'm hoping to go back to college next term to do the tig level 1.

Welding mild steel about 3mm

Using about 75 amps with 1.6 filler

Now i could lay down 3 straight welds with the help of a line on the steel.

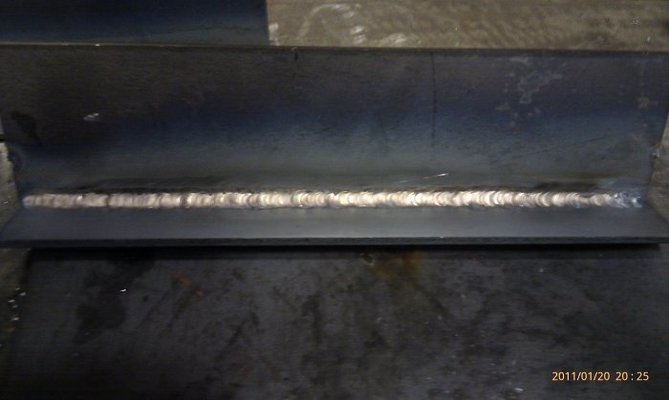

So i turned to the next test piece, a lap joint. Left the amps at 75 and managed to crack it on the third attempt.

Next was the fillet. Now this im struggling on. I tried it at 80 amps and 85 but found there was way to much undercut especially on the vertical edge.

I then tried again dropping it down to 75 again but again undercut on the vertical.

Im adding the filler from the vertical edge but its just as bad.

Should i drop the amps a little more and move slower or shall i add more filler?

Ill post some pics up next week after ive been on thursday night.

Any advice would be appreciated.

Thanks

Ian

Welding mild steel about 3mm

Using about 75 amps with 1.6 filler

Now i could lay down 3 straight welds with the help of a line on the steel.

So i turned to the next test piece, a lap joint. Left the amps at 75 and managed to crack it on the third attempt.

Next was the fillet. Now this im struggling on. I tried it at 80 amps and 85 but found there was way to much undercut especially on the vertical edge.

I then tried again dropping it down to 75 again but again undercut on the vertical.

Im adding the filler from the vertical edge but its just as bad.

Should i drop the amps a little more and move slower or shall i add more filler?

Ill post some pics up next week after ive been on thursday night.

Any advice would be appreciated.

Thanks

Ian