WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

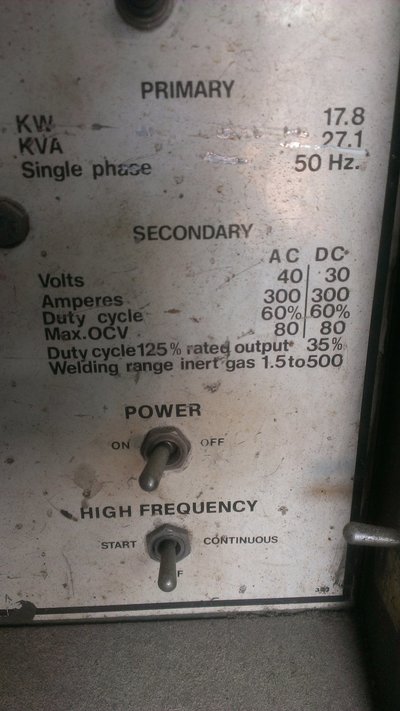

A cooler has been on my list to build for a while, its not a priority as i still have to restore my miller 500A to go with it.

But having seen beer coolers mentioned on a few post recently in relation to torch cooling i thought it would be good to investigate.

I was skeptical to start with as having worked in a pub in the past i couldn't see how one of the small cooler would be much use.

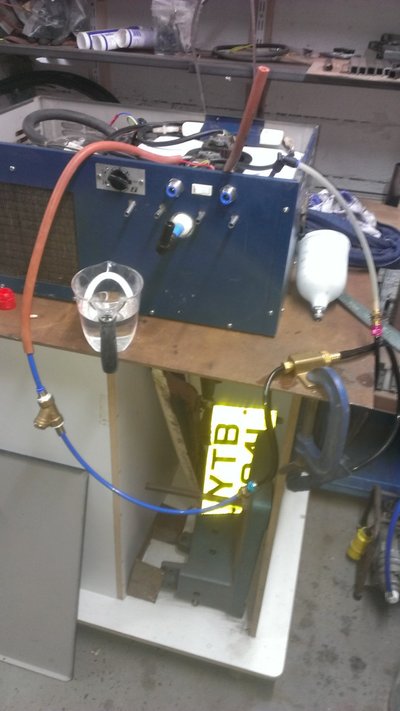

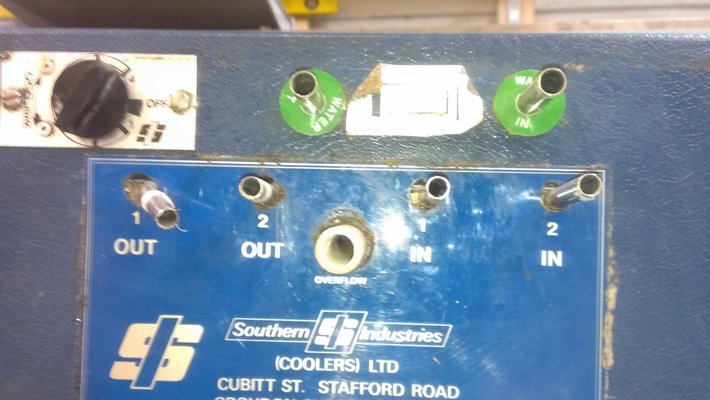

Then Friday i spotted one locally for a good price that had a additional pump fitted, they are normally used to pump cooled water around a insulated jacket to cool casks.

A standard cooler contains no pump just a number off cooling loops to act as heat exchangers. Under normal circumstances the beer is not pumped as the keg is pressurized with Co2.

I have only got as far as opening it up to take a few photos.

At the moment i am not expecting the pump to be of any use, as its just a tiny washing machine pump.

Once i have cleaned it up i will test to see how much pressure and flow we have.

So we have a compressor pump, heat exchanger and fan.

With a plastic double walled insulated tank.

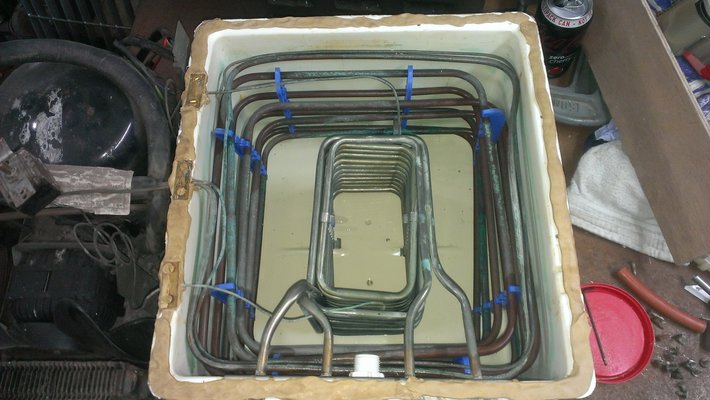

The copper refrigerant coils run round the outside, with the stainless exchanger coils in the middle.

Then in the top sit the pump and an agitator.

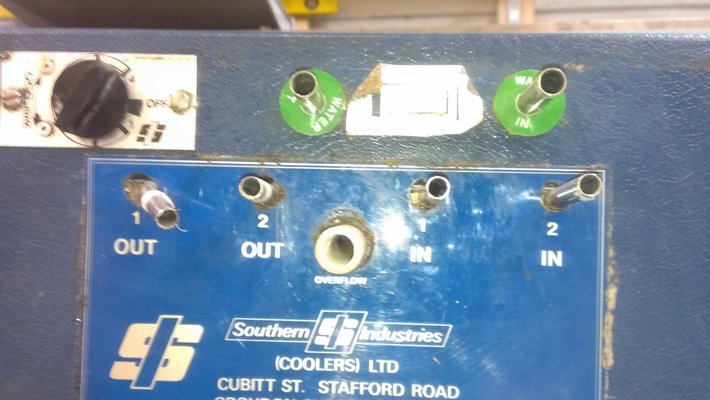

Once i get it cleaned up i will report back and update with the tank capacity and the pump performance.

But having seen beer coolers mentioned on a few post recently in relation to torch cooling i thought it would be good to investigate.

I was skeptical to start with as having worked in a pub in the past i couldn't see how one of the small cooler would be much use.

Then Friday i spotted one locally for a good price that had a additional pump fitted, they are normally used to pump cooled water around a insulated jacket to cool casks.

A standard cooler contains no pump just a number off cooling loops to act as heat exchangers. Under normal circumstances the beer is not pumped as the keg is pressurized with Co2.

I have only got as far as opening it up to take a few photos.

At the moment i am not expecting the pump to be of any use, as its just a tiny washing machine pump.

Once i have cleaned it up i will test to see how much pressure and flow we have.

So we have a compressor pump, heat exchanger and fan.

With a plastic double walled insulated tank.

The copper refrigerant coils run round the outside, with the stainless exchanger coils in the middle.

Then in the top sit the pump and an agitator.

Once i get it cleaned up i will report back and update with the tank capacity and the pump performance.