You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taper Turning Attachment.

- Thread starter Mr shiney

- Start date

doubleboost

Member

- Messages

- 3,871

- Location

- Newcastle upon Tyne England

It goes in the tail stock

Should really use a "ball centre"

Turns tapers between centres

Should really use a "ball centre"

Turns tapers between centres

MattF

Forum Supporter

- Messages

- 17,659

- Location

- South Yorkshire

There should be a pin of the same diameter as those holes in the front plate. Align the respective hole on that front plate with the single hole on the rear plate and insert the pin to locate both pieces, then tighten the bolts up to lock it tight. That needs to be parallel to the bed ways when you use it, btw.

MattF

Forum Supporter

- Messages

- 17,659

- Location

- South Yorkshire

Any identifying marks on it? It'll probably be a black art to set up reliably at the best of times, as it'll likely need to be a specific distance from the headstock too, so if there's owt on there you can find the source from for chasing for instructions, it'd be easier.

Pete.

Member

- Messages

- 14,868

- Location

- Kent, UK

You can set it up with a dial indicator. Say for instance you want to turn a Jarno taper, that's 1 in 20. First you measure the length of bar you want to turn, lets say it's 200mm. 1:20 over 200mm is 10mm, half that is 5mm (because when you turn a taper you're turning both sides so whatever you off-set by is doubled) so bring your tailstock fitting up to the headstock centre and set the points as close to 5mm apart as you can measure with a ruler.

Once you have done that mount the bar between the centres. Now set a dial gauge on the toolpost exactly level at exactly centre height. Bring it in to touch the work, set a stop on the bed to stop the carriage in the same place every time. Once the dial tip is touching you move the carriage along a set amount and watch the dial gauge turn. If you have 200mm of bar then sweep along 200mm and the dial should move 5mm. If it moves more, your angle is too great so move the centre back towards middle a bit. If it moves less, your angle is too shallow so add some off-set. YOu don't have to use the whole length of the bar but the longer your sweep, the closer your angle will be.

Once you have done that mount the bar between the centres. Now set a dial gauge on the toolpost exactly level at exactly centre height. Bring it in to touch the work, set a stop on the bed to stop the carriage in the same place every time. Once the dial tip is touching you move the carriage along a set amount and watch the dial gauge turn. If you have 200mm of bar then sweep along 200mm and the dial should move 5mm. If it moves more, your angle is too great so move the centre back towards middle a bit. If it moves less, your angle is too shallow so add some off-set. YOu don't have to use the whole length of the bar but the longer your sweep, the closer your angle will be.

Pete.

Member

- Messages

- 14,868

- Location

- Kent, UK

BTW I don't know what use the holes are. Seems daft to me because they will only work with one exact length of workpiece. If you use a longer or shorter piece of material, or een if the centres are drilled deeper, the holes will give the wrong taper.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 18,010

- Location

- East Yorkshire

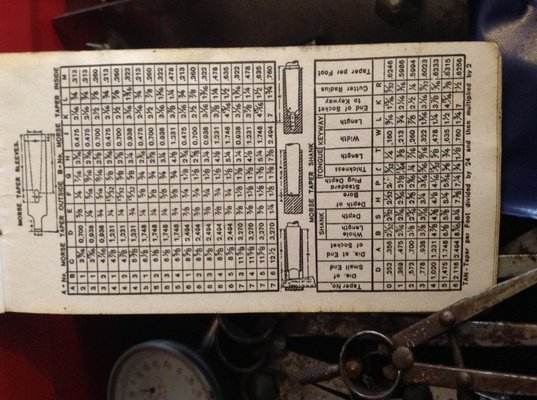

Do you happen to have the ratio for the MT tapers?

Each MT taper is different. google is your friend

OK, courtesy of Wikipedia and reproduced here in accordance with Wikipedia terms and giving full credit.

http://en.wikipedia.org/wiki/Machine_taper

Morse Taper numberTaperAB (max)C (max)D (max)E (max)FGHJK

0 1:19.212 9.045 56.559.510.564133.91° 29' 26"

1 1:20.047 12.06 56265.513.58.751.23.55.21° 25' 43"

2 1:20.020 17.78 075801613.561.656.31° 25' 50"

3 1:19.922 23.82 594992018.57257.91° 26' 16"

4 1:19.254 31.26 7117.51242424.582.56.511.91° 29' 15"

5 1:19.002 44.399149.51562935.71036.515.91° 30' 26"

6 1:19.180 63.34 821021840511348191° 29' 36"

7 1:19.231 83.05 8285.75294.134.9--19.05-191° 29' 22"

http://en.wikipedia.org/wiki/Machine_taper

Morse Taper numberTaperAB (max)C (max)D (max)E (max)FGHJK

0 1:19.212 9.045 56.559.510.564133.91° 29' 26"

1 1:20.047 12.06 56265.513.58.751.23.55.21° 25' 43"

2 1:20.020 17.78 075801613.561.656.31° 25' 50"

3 1:19.922 23.82 594992018.57257.91° 26' 16"

4 1:19.254 31.26 7117.51242424.582.56.511.91° 29' 15"

5 1:19.002 44.399149.51562935.71036.515.91° 30' 26"

6 1:19.180 63.34 821021840511348191° 29' 36"

7 1:19.231 83.05 8285.75294.134.9--19.05-191° 29' 22"

I have a zeus book but find the old world measurements a little difficult to get my head around!!!

I have a zeus book but find the old world measurements a little difficult to get my head around!!!