I generally use my welder for 2-3mm steel.. I have done thin work, but never worried about finish. But today i decided to have a crack at cutting a hole in some 0.8mm sheet and then welding in a patch.

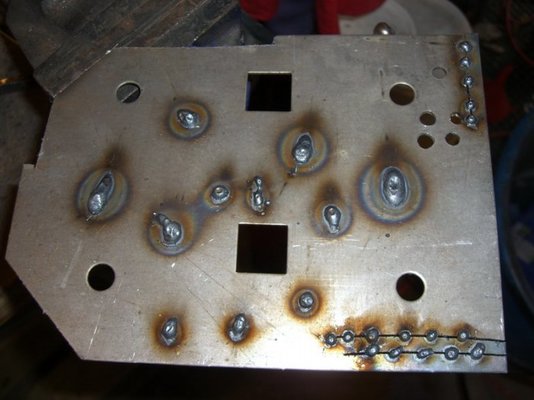

I cut the hole.. Made a patch.. And tacked it in place.. Then started welding it, using overlapping "spots" with 1 second pauses between welds.

The first 8 spots went well.. Very well.. But then i started blowing through.. My assumption was that the area was too hot, so i moved to the other side of the patch and blew holes in that too..

It was almost like my welder had incresed its current mid way through... I started to randomly try to work out what was wromg and before long i had run out of space...

Before i try again, does anyone have any idea what went wrong?

Jon

I cut the hole.. Made a patch.. And tacked it in place.. Then started welding it, using overlapping "spots" with 1 second pauses between welds.

The first 8 spots went well.. Very well.. But then i started blowing through.. My assumption was that the area was too hot, so i moved to the other side of the patch and blew holes in that too..

It was almost like my welder had incresed its current mid way through... I started to randomly try to work out what was wromg and before long i had run out of space...

Before i try again, does anyone have any idea what went wrong?

Jon