gasket999

getting there...

- Messages

- 377

- Location

- Manchester, UK

Hi folks.

I'm starting to make myself a rivet squeezer for 3/16 aluminium aircraft rivets. I've used air hammers in the past, but prefer the control of a little squeezer (plus I work alone, so holding a dolly is a bit tough).

At the ends of the squeezer I'll be using a welded, cut off snap on one leg and either the small hydraulic ram from my puller on the other side (or a simple G-clamp threaded rod) to gently compress the rivet.

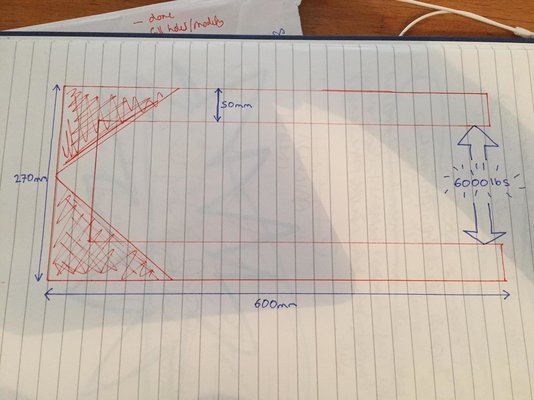

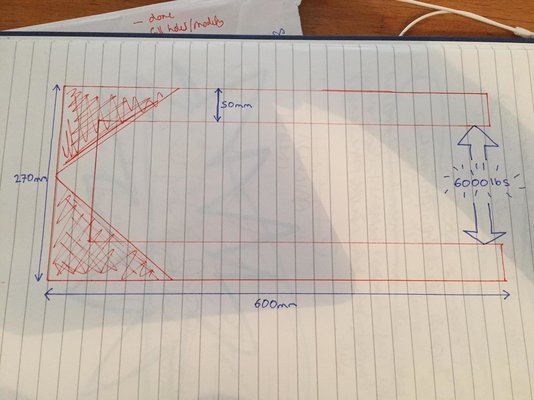

It needs to have quite a long reach for some jobs (I'll brace across for the more frequent shallow reaches) - in 2D I've got it laid out having made it as deep as I could get away with, but I wondered if someone could advise on how thick the tool would need to be to withstand the force?

I'm looking to make the legs out of either 50mm bar or out of 50mm rectangular tube. The X-factor is how thick I would need either material to be.

The bar I have in the workshop is 10mm thick and I could layer it up twice or three times-over to give a 2030mm x 50mm solid piece. I don't have the tube so if this is a better solution I can buy a size/thickness to suit. I can add small gussets at the back, but not too much as it would interfere with the reach.

If anyone could advise - obviously not expecting any calculations - just a rough idea/feel from people who do more fabrication than I do.

I can't find out how much force it takes to properly compress a 3/16 solid aluminium rivet, but some of the commercial squeezers list 6000lbs - which sounds like a lot when you can shape a rivet with light blows from a ball pen hammer. My little SP hydraulic ram will go considerably higher (about 10,000lbs) so I'll have to be disciplined to stop when the rivet is crushed.

Many thanks indeed.

I'm starting to make myself a rivet squeezer for 3/16 aluminium aircraft rivets. I've used air hammers in the past, but prefer the control of a little squeezer (plus I work alone, so holding a dolly is a bit tough).

At the ends of the squeezer I'll be using a welded, cut off snap on one leg and either the small hydraulic ram from my puller on the other side (or a simple G-clamp threaded rod) to gently compress the rivet.

It needs to have quite a long reach for some jobs (I'll brace across for the more frequent shallow reaches) - in 2D I've got it laid out having made it as deep as I could get away with, but I wondered if someone could advise on how thick the tool would need to be to withstand the force?

I'm looking to make the legs out of either 50mm bar or out of 50mm rectangular tube. The X-factor is how thick I would need either material to be.

The bar I have in the workshop is 10mm thick and I could layer it up twice or three times-over to give a 2030mm x 50mm solid piece. I don't have the tube so if this is a better solution I can buy a size/thickness to suit. I can add small gussets at the back, but not too much as it would interfere with the reach.

If anyone could advise - obviously not expecting any calculations - just a rough idea/feel from people who do more fabrication than I do.

I can't find out how much force it takes to properly compress a 3/16 solid aluminium rivet, but some of the commercial squeezers list 6000lbs - which sounds like a lot when you can shape a rivet with light blows from a ball pen hammer. My little SP hydraulic ram will go considerably higher (about 10,000lbs) so I'll have to be disciplined to stop when the rivet is crushed.

Many thanks indeed.

Last edited:

), which means the two arms will spread out by more than 8 inches (And that's ignoring that the back would bend too and the 16000Nm torque at each corner of the frame which I'm pretty sure would exceed the tensile strength of the steel).

), which means the two arms will spread out by more than 8 inches (And that's ignoring that the back would bend too and the 16000Nm torque at each corner of the frame which I'm pretty sure would exceed the tensile strength of the steel).