Kram

Member

- Messages

- 7,726

- Location

- Sussex

Looks relatively easy, I'm not sure why its not standard, it'd be cheaper to make and only cost them maybe half hour more design to make it small and a cover

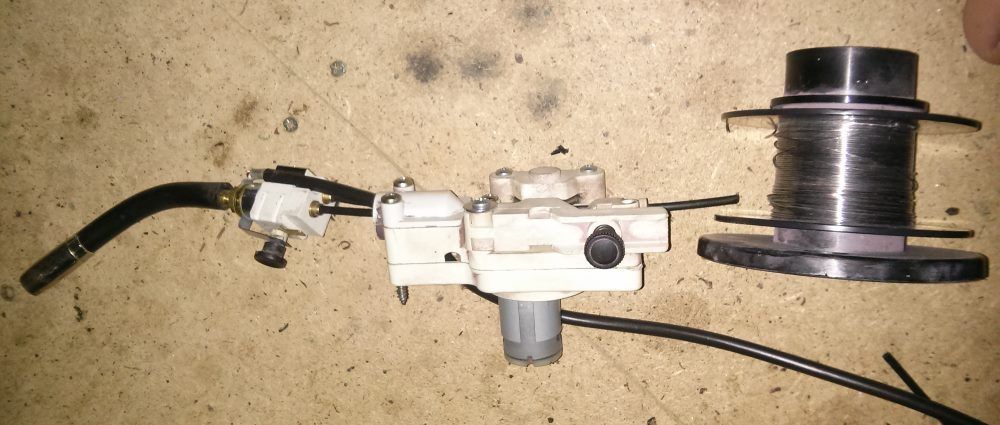

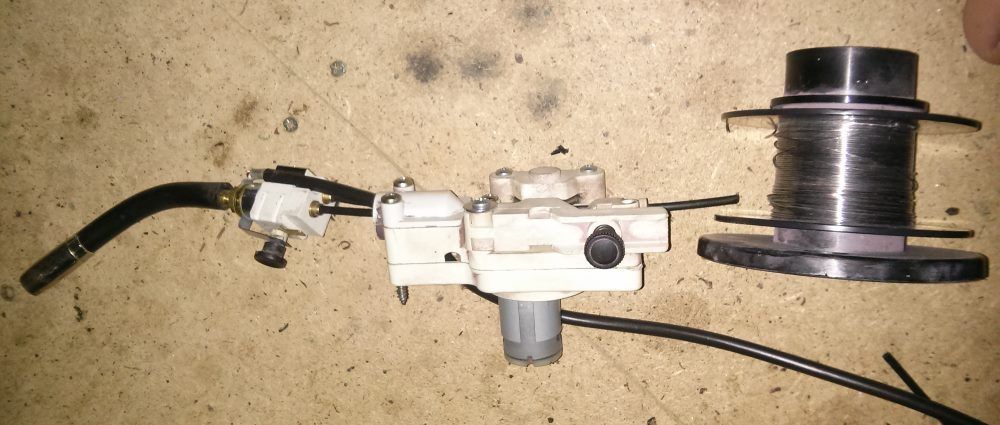

Changes needed are to extend the motor wires which are low voltage (12/24v?) and mount the spool and feed holder to the torch. And a cover. Lots of improvements are possible my plan:

my plan:

Spool on torch

Front case connector for wires (swappable +/-, switch wire), removable mains plug goes in back of case

Connector on torch for gas hose, as I mostly use gasless.

Half width, lighter (0.6mm) aluminium case

Stupid question, how the hell do you remove the liner or gas hose from the torch switch?!? the brass bit turns, but neither pull out

Once its working, Ill make a much smaller feed/torch. I'm tempted to add a stepper motor for consistent speed / higher torque.

Im going to try aluminium soon after this is done, and thought it'd be cheaper than a new liner. Plus I dont like wasting the last two meters on a spool..

Changes needed are to extend the motor wires which are low voltage (12/24v?) and mount the spool and feed holder to the torch. And a cover. Lots of improvements are possible

my plan:

my plan:Spool on torch

Front case connector for wires (swappable +/-, switch wire), removable mains plug goes in back of case

Connector on torch for gas hose, as I mostly use gasless.

Half width, lighter (0.6mm) aluminium case

Stupid question, how the hell do you remove the liner or gas hose from the torch switch?!? the brass bit turns, but neither pull out

Once its working, Ill make a much smaller feed/torch. I'm tempted to add a stepper motor for consistent speed / higher torque.

Im going to try aluminium soon after this is done, and thought it'd be cheaper than a new liner. Plus I dont like wasting the last two meters on a spool..

..)

..)