You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sealey Pro Mig

- Thread starter paul6843

- Start date

cumbriasteve

Moderator

- Messages

- 9,645

- Location

- Cumbria UK

Welcome to the forum

Some idea of your welding requirements will help with advice, I am not up to speed with Sealey but if you do a search you should find loads of posts which may help

Some idea of your welding requirements will help with advice, I am not up to speed with Sealey but if you do a search you should find loads of posts which may help

Do you have a dedicated supply for the 190? It will need quite a bit more power than the 230v 13Amp domestic plug and socket can supply.

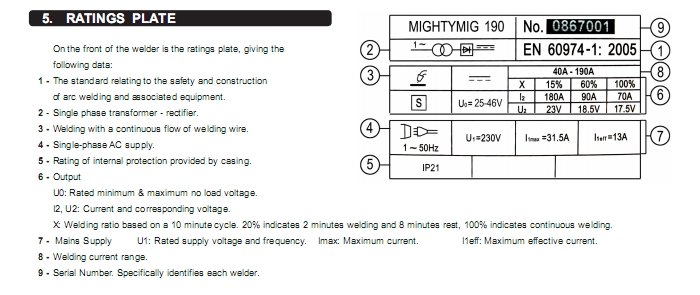

It also only goes down to 40 Amps output, so making it more difficult to use on thin panels, car bodywork, etc. See pic of the ratings plate, from the manual:

It also only goes down to 40 Amps output, so making it more difficult to use on thin panels, car bodywork, etc. See pic of the ratings plate, from the manual:

Thanks for the info.

I have a deicated 30amp supply for the mig. The work I intend to use the mig for is finishing my logsplitter project and making new gates for my garage. Car body repair is not high on my list of things todo unless my kids have other ideas . Metal thickness to be used can range from 0.5-10mm.

. Metal thickness to be used can range from 0.5-10mm.

I have a deicated 30amp supply for the mig. The work I intend to use the mig for is finishing my logsplitter project and making new gates for my garage. Car body repair is not high on my list of things todo unless my kids have other ideas

. Metal thickness to be used can range from 0.5-10mm.

. Metal thickness to be used can range from 0.5-10mm.With 40A low output, you are looking at around 1.2 mm m/s upwards for a reasonable skill level, but if you've had plenty experience you may be able to go a bit lower, using heat sinks behind the job, etc.

If you want to go down to 0.5 mm m/s regularly forget this machine; it will just blow the steel away, even with heat sinks the arc is likely to be too powerful. I used to use a Sealey 150 Pro in workshop use, it went down to 35A, and it really needed getting used to for bodywork repairs. On thin stuff we used all sorts of long-handled back spoons and heat sinks to take the heat away. Higher up the range it did a good job, reliable, no complaints.

At the top end an output of 15% at 180A will be struggling to do much 10 mm welding, unless you do multiple runs. Personally I'd rather have something with a top end of 250 - 270A for regular welding at this thickness. Or get the arc welder out instead and make multiple runs.

The Sealey 190 should be a decent enough mid-range machine, but it neither goes down low enough at one end, or high enough at the other, for the range of steel thicknesses you list. I think I would be looking around for a proper 'Pro' machine s/h for awhile before going for the 190, especially as you have welding experience which comes in handy when you're testing a machine.

If you want to go down to 0.5 mm m/s regularly forget this machine; it will just blow the steel away, even with heat sinks the arc is likely to be too powerful. I used to use a Sealey 150 Pro in workshop use, it went down to 35A, and it really needed getting used to for bodywork repairs. On thin stuff we used all sorts of long-handled back spoons and heat sinks to take the heat away. Higher up the range it did a good job, reliable, no complaints.

At the top end an output of 15% at 180A will be struggling to do much 10 mm welding, unless you do multiple runs. Personally I'd rather have something with a top end of 250 - 270A for regular welding at this thickness. Or get the arc welder out instead and make multiple runs.

The Sealey 190 should be a decent enough mid-range machine, but it neither goes down low enough at one end, or high enough at the other, for the range of steel thicknesses you list. I think I would be looking around for a proper 'Pro' machine s/h for awhile before going for the 190, especially as you have welding experience which comes in handy when you're testing a machine.