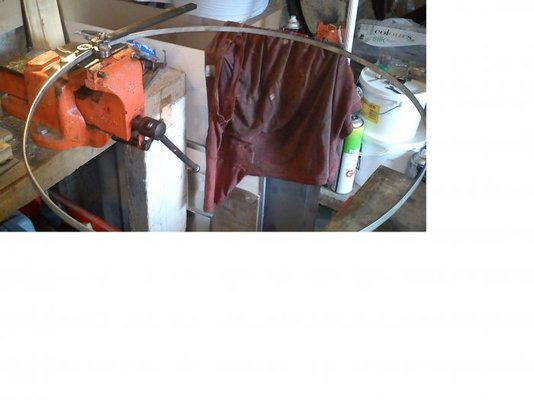

I hacked together a simple RR based on the version I posted last week

Generally good results and answered a lot of questions.

I only wanted something that would form 12x3mm stainless

I used nylon (oilon) for the slave rollers and a bolt head for the driver.

These worked well with no distortion apparent either on the rollers or on the workpiece.

I did the ring shown in 1 pass. I did a 12" ring in 2 passes to avoid strain on the rollers.

Horizontal ring rollers are clumsy in use with the workpiece exerting a lot of torque on the rollers as the ring forms. so you need some sort of support. My tool trolley did that nicely

I didn't knurl the driver roller and found this wasn't necessary for the lightweight stuff I worked on. I could have easily formed 12x6mm stuff without straining anything or slippage of the workpiece

Lessons learned;

1) I forgot to turn some circlip grooves in the inner set of pegs before I welded them in place, so the nylon rollers kept lifting off the pegs with the torque.

2) I should have cut the form in the rollers deeper than the 0.7mm I did. I thought the rollers might clash, but they were nowhere near that.

3) Standing inside the ring helps to get at the torque bar but it means that you are trying to watch two ends behind your back.

4) Vices should be serviced regularly. Although I grease mine fairly often I had never removed the jaws and one bolt was completely siezed and snapped. Now I can't find what thread size fits - my BSW and metric thread gauges dont identify the pitch at all.

Ian

Generally good results and answered a lot of questions.

I only wanted something that would form 12x3mm stainless

I used nylon (oilon) for the slave rollers and a bolt head for the driver.

These worked well with no distortion apparent either on the rollers or on the workpiece.

I did the ring shown in 1 pass. I did a 12" ring in 2 passes to avoid strain on the rollers.

Horizontal ring rollers are clumsy in use with the workpiece exerting a lot of torque on the rollers as the ring forms. so you need some sort of support. My tool trolley did that nicely

I didn't knurl the driver roller and found this wasn't necessary for the lightweight stuff I worked on. I could have easily formed 12x6mm stuff without straining anything or slippage of the workpiece

Lessons learned;

1) I forgot to turn some circlip grooves in the inner set of pegs before I welded them in place, so the nylon rollers kept lifting off the pegs with the torque.

2) I should have cut the form in the rollers deeper than the 0.7mm I did. I thought the rollers might clash, but they were nowhere near that.

3) Standing inside the ring helps to get at the torque bar but it means that you are trying to watch two ends behind your back.

4) Vices should be serviced regularly. Although I grease mine fairly often I had never removed the jaws and one bolt was completely siezed and snapped. Now I can't find what thread size fits - my BSW and metric thread gauges dont identify the pitch at all.

Ian