krs

New Member

- Messages

- 2

- Location

- berlin

Hello, I've been welding with a Selco for several years.

I bought this welder used. From the very beginning, it didn't weld with an electrode. When welding with an electrode, it would cut off the welding current immediately after the electrode touched the material. (After that, I could hear a slight clicking sound in the welder, which stopped when I switched to the TIG function.)

So I only used the TIG function, and the welder welded very well. Recently, while cleaning, I noticed that the K1 jumper was soldered. I desoldered the K1 jumper and simply continued using the welder in the TIG function. A month ago, I also used the MMA function and, surprisingly, it welded. I was happy.

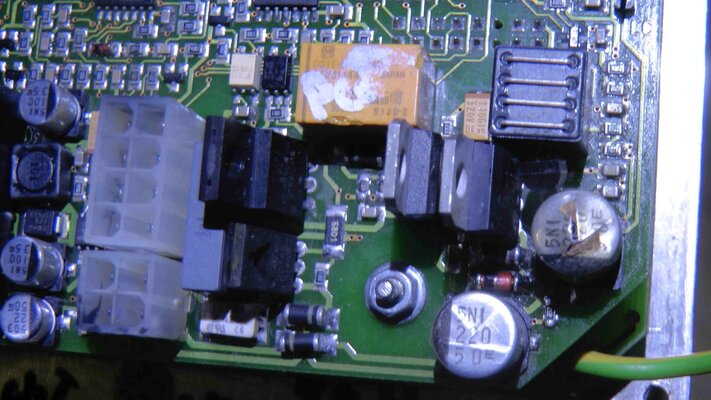

After maybe 10 MMA welds, surprise, something popped inside. On the control panel (lower right side of the panel), a 220uf/50V SMD capacitor (C67) was damaged.

I had a second panel to replace it, so I installed it. After a few minutes of welding, the same thing happened. A 220uf/50V SMD capacitor (C67) was damaged on the panel.

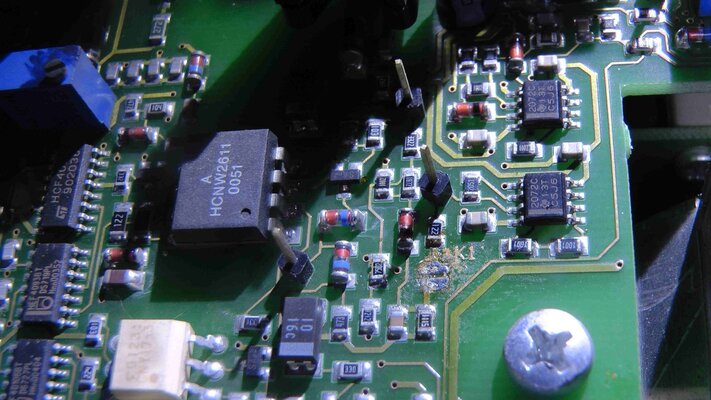

I measured it with a multimeter, and in the second case, the red Zener diode (Z2 - I think it's 5.1V) was also damaged (next to the capacitor), as were the L7815cv voltage regulator (IC20) and the 5V regulator (IC21).

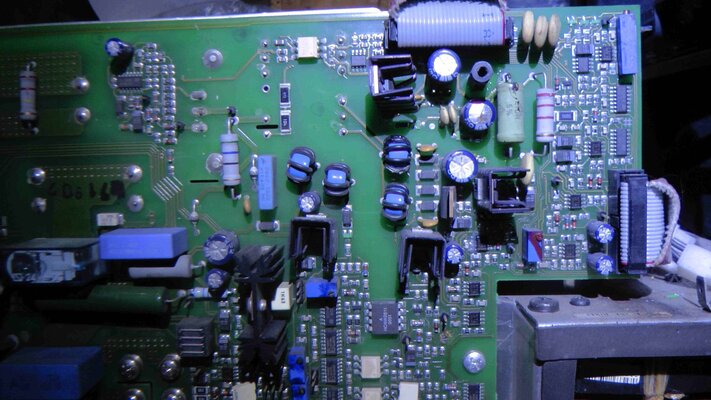

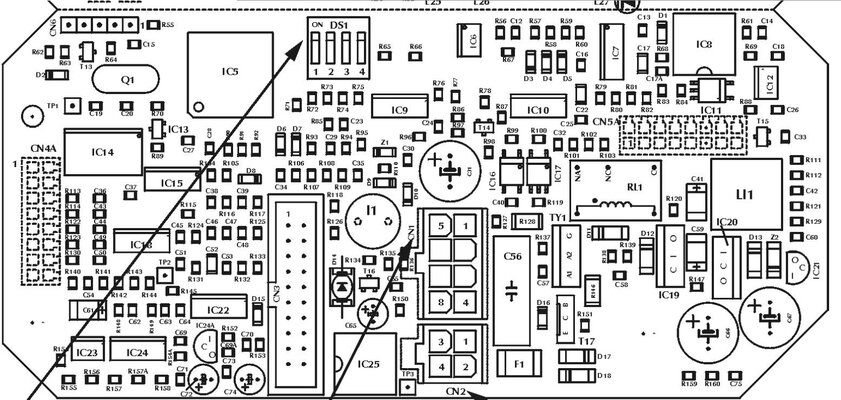

Next, on the motherboard in the additional voltage section. (upper right side of the board) the C33 capacitor - 100uf/63v (next to the green 270ohm resistor) was damaged.

My question is...

Was the cause of the panel failure the THT 100uf/63v capacitor on the motherboard (next to the green 270ohm resistor)?

Should I replace all the damaged components with new ones and try welding them? Or should I look for the cause of the damage somewhere else?

Motherboard version no. 4

(If anyone needs it, I had several of these welders with different motherboard versions and have photos)

Regards

Peter

I bought this welder used. From the very beginning, it didn't weld with an electrode. When welding with an electrode, it would cut off the welding current immediately after the electrode touched the material. (After that, I could hear a slight clicking sound in the welder, which stopped when I switched to the TIG function.)

So I only used the TIG function, and the welder welded very well. Recently, while cleaning, I noticed that the K1 jumper was soldered. I desoldered the K1 jumper and simply continued using the welder in the TIG function. A month ago, I also used the MMA function and, surprisingly, it welded. I was happy.

After maybe 10 MMA welds, surprise, something popped inside. On the control panel (lower right side of the panel), a 220uf/50V SMD capacitor (C67) was damaged.

I had a second panel to replace it, so I installed it. After a few minutes of welding, the same thing happened. A 220uf/50V SMD capacitor (C67) was damaged on the panel.

I measured it with a multimeter, and in the second case, the red Zener diode (Z2 - I think it's 5.1V) was also damaged (next to the capacitor), as were the L7815cv voltage regulator (IC20) and the 5V regulator (IC21).

Next, on the motherboard in the additional voltage section. (upper right side of the board) the C33 capacitor - 100uf/63v (next to the green 270ohm resistor) was damaged.

My question is...

Was the cause of the panel failure the THT 100uf/63v capacitor on the motherboard (next to the green 270ohm resistor)?

Should I replace all the damaged components with new ones and try welding them? Or should I look for the cause of the damage somewhere else?

Motherboard version no. 4

(If anyone needs it, I had several of these welders with different motherboard versions and have photos)

Regards

Peter