Hi Folks,

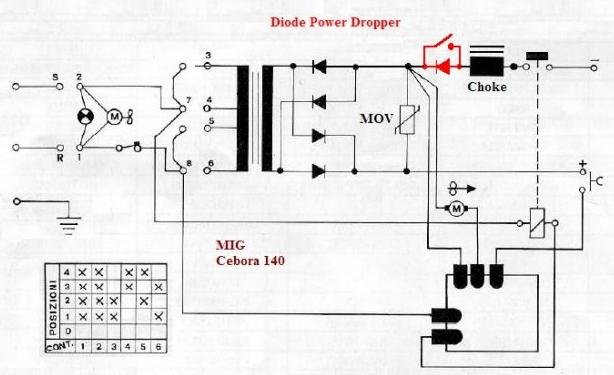

I use a very old Cebora 140 MIG and have disaster after disaster welding thin steel sheet. 1.6 mm is ok for me but thinner is a molten mess. So I decided to have a go at adding a power diode in the negative output rail to see if a small voltage drop of about 0.7 volt dc would reduce the minimum power setting to a usable power level for me welding 1 mm steel sheet with the old Cebora. I realise that more proficient MIG welders some how weld even thinner than 1 mm and that modern MIGs with more dials and buttons than a 747 probably can weld very very thin metals.

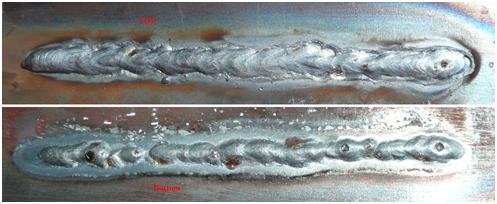

So after adding the power diode consisting of 6 diodes (from the junk box) in parallel (35 amp 100 volt working) to get a sufficient power rating but not ideal by any means I gave it a try and the 1st shaky result is in the attached pic. The steel is 1 mm thick and the weld is approx 95 mm long. Obviously a lot more practice is required but for me I can now MIG weld 1 mm steel but it looks so yucky. Practice, practice, practice.

Cheers,

Crackle

I use a very old Cebora 140 MIG and have disaster after disaster welding thin steel sheet. 1.6 mm is ok for me but thinner is a molten mess. So I decided to have a go at adding a power diode in the negative output rail to see if a small voltage drop of about 0.7 volt dc would reduce the minimum power setting to a usable power level for me welding 1 mm steel sheet with the old Cebora. I realise that more proficient MIG welders some how weld even thinner than 1 mm and that modern MIGs with more dials and buttons than a 747 probably can weld very very thin metals.

So after adding the power diode consisting of 6 diodes (from the junk box) in parallel (35 amp 100 volt working) to get a sufficient power rating but not ideal by any means I gave it a try and the 1st shaky result is in the attached pic. The steel is 1 mm thick and the weld is approx 95 mm long. Obviously a lot more practice is required but for me I can now MIG weld 1 mm steel but it looks so yucky. Practice, practice, practice.

Cheers,

Crackle