hotponyshoes

Member

- Messages

- 7,809

- Location

- Somerset. Uk

Probably better asking this on here than a catering forum!

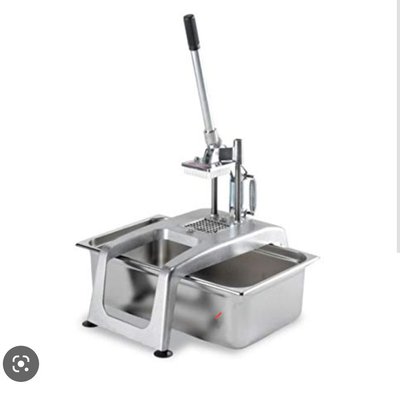

I've obtained a cutter thing for making chips.

It's hand powered so not exactly a high speed or precision tool

Basically you pull the handle and the top bit moves up and down the 2 shafts in the picture.

Now these have worn quite badly and, although it's not a precision tool there is enough slop that the spud pusher die catches on the blades if you don't hold the handle in just the right position which makes it slow to use which defeats the whole point of having it.

The 2 shafts are some sort of magnetic steel. Inside the alloy housing are bushes (I'm guessing bronze) that are probably pressed into place.

The shafts themselves are not so much of an issue as I don't think they have worn much. They is a bit of corrosion but I reckon I could polish them both up ok.

Then maybe just press the bushes out and replace them with new ones?

But, the O/D of the shafts is about 15.4mm.

The O/D of the bushes is maybe 18mm

The I/D of the bushes is about 15.8mm depending where you read it.

Length of the bushes is about 60mm.

Is it likely that a 60mm x 18mm/15.5mm bush would be a standard stock part?

And if it was, would 0.1mm be a suitable clearance for this sort of thing?

Or are they more likely to be imperial sized?

(It's a modern European machine though)

I'm fairly optimistic that I can get the old bushes out. I can heat the whole alloy block if required or cut them etc and should be able to press the new ones in if I can find them.

The other thing I though of doing is trying to ream the bushes out to 16mm (or whatever size reamer I can find) then get some new bar (maybe stainless) but the bars have a step and a thread and I need 2 of them so there will be a bit of machining involved plus the bushes have worn oval and I'm not convinced they won't pick up and start spinning if I try reaming them?

I've obtained a cutter thing for making chips.

It's hand powered so not exactly a high speed or precision tool

Basically you pull the handle and the top bit moves up and down the 2 shafts in the picture.

Now these have worn quite badly and, although it's not a precision tool there is enough slop that the spud pusher die catches on the blades if you don't hold the handle in just the right position which makes it slow to use which defeats the whole point of having it.

The 2 shafts are some sort of magnetic steel. Inside the alloy housing are bushes (I'm guessing bronze) that are probably pressed into place.

The shafts themselves are not so much of an issue as I don't think they have worn much. They is a bit of corrosion but I reckon I could polish them both up ok.

Then maybe just press the bushes out and replace them with new ones?

But, the O/D of the shafts is about 15.4mm.

The O/D of the bushes is maybe 18mm

The I/D of the bushes is about 15.8mm depending where you read it.

Length of the bushes is about 60mm.

Is it likely that a 60mm x 18mm/15.5mm bush would be a standard stock part?

And if it was, would 0.1mm be a suitable clearance for this sort of thing?

Or are they more likely to be imperial sized?

(It's a modern European machine though)

I'm fairly optimistic that I can get the old bushes out. I can heat the whole alloy block if required or cut them etc and should be able to press the new ones in if I can find them.

The other thing I though of doing is trying to ream the bushes out to 16mm (or whatever size reamer I can find) then get some new bar (maybe stainless) but the bars have a step and a thread and I need 2 of them so there will be a bit of machining involved plus the bushes have worn oval and I'm not convinced they won't pick up and start spinning if I try reaming them?